精湛的部件工艺,非凡的专业技术铸就。

我们的每项服务都经过精雕细琢,以满足您独特的原型设计和生产要求。我们的技术敏锐度延伸至最先进的方法,包括数控加工的精密艺术、注塑成型的变革魔力、钣金制造的建筑优雅等等。请委托我们为您的原型或部件注入生命力。

- 服务 3000 多家公司

- 生产了 200,000 + 个独特零件

- 合作的供应商超过 300 家

- 首页

- 我们的能力

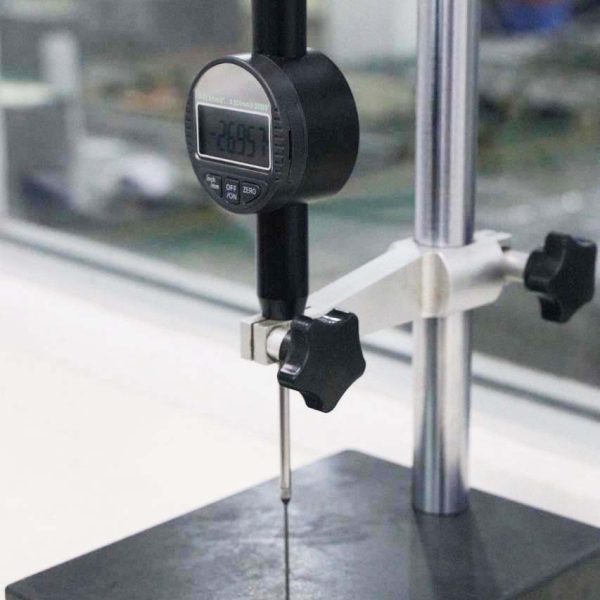

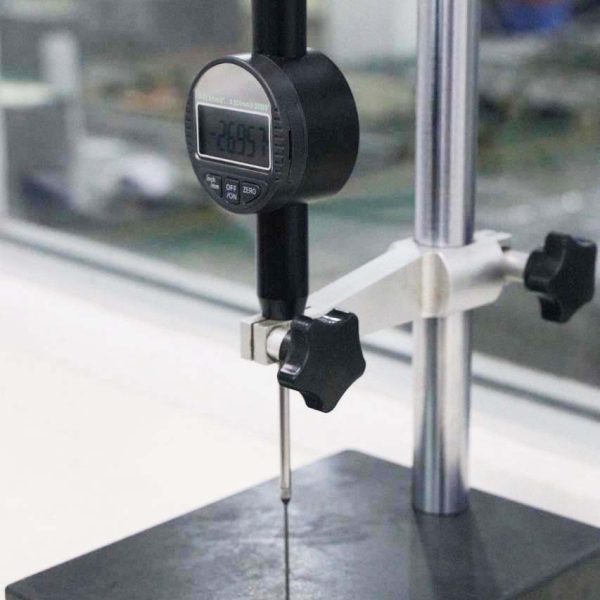

矢志不渝,打造精品。

凭借 14 年的集体智慧,我们经验丰富的工程师团队对设计蓝图进行了一丝不苟的审查和改进。他们致力于优化卓越的性能、经济的解决方案和无缝的模具生产。我们对每项设计都进行了细致的检查,并对许多关键环节进行了严格把关,以确保生产出真正质量上乘、工艺精湛的模具。

重点更突出,专业性无与伦比。

- 壁厚

- 美学

- 收缩

- 尺寸稳定性

- 压力

- 费用

- 功能性

铝质

铝这种金属具有出色的强度重量比。对于飞机托架和外壳的高负载要求来说,铝是一个不错的选择。铝还具有良好的延展性、刚度、耐腐蚀性和可加工性。其轻质特性使其适用于机身蒙皮、机翼弦杆、机翼蒙皮等航空结构应用。

价格 $

交货时间: < 10 天

公差: ±0.125毫米(±0.005英寸)

最大零件尺寸: 200 x 80 x 100 厘米

钛

钛具有多种材料特性,是高要求应用领域的理想金属。这些特性包括出色的耐腐蚀性、耐化学性和耐极端温度性。此外,钛还具有出色的强度重量比。

这些特性使钛合金成为机身和飞机发动机的最佳选择。

价格 $$$

交货时间: < 10 天

壁厚 0.75 毫米

公差: ±0.125毫米(±0.005英寸)

最大零件尺寸: 200 x 80 x 100 厘米

不锈钢

钢是另一种可用于生产现代汽车零部件的金属。这种金属经久耐用,性能高效。它还有利于生产高质量的零件。它耐腐蚀、重量轻,能生产出美观的零件。这种金属可用于生产汽车制动器、发动机、排气系统、车轮等。

价格 $

交货时间: < 10 天

壁厚 0.75 毫米

公差: ±0.125毫米(±0.005英寸)

最大零件尺寸: 200 x 80 x 100 厘米

铜

铜在汽车工业的舒适性、效率和安全性方面发挥着巨大作用。铜是一种优良的导电体,具有很高的延展性和可塑性。它适用于汽车的大部分电子元件,包括汽车线束、散热器、启动电机、交流发电机和制动管。

价格 $

交货时间: <10天

公差: ±0.125毫米

最大部件尺寸: 200 x 80 x 100 厘米

镁

镁重量轻,具有出色的可铸造性和较高的比强度,因此可用于汽车行业。镁可用于生产发动机缸体、变速箱、离合器壳体、车轮和发动机支架以及油盘。

价格 $

准备时间 <10天

公差: ±0.125毫米

最大部件尺寸: 200 x 80 x 100 厘米

热塑性塑料

汽车行业使用的热塑性塑料种类很多,包括高密度聚乙烯、聚丙烯、丙烯酸、聚碳酸酯、PPS、ABS 和 PC-ABS。这些热塑性塑料具有优异的性能,从高抗冲击性到耐高温能力,不一而足。聚苯乙烯(PPS)。例如,它具有出色的尺寸稳定性、耐温性和抗硬性。热塑性塑料可用于汽车内饰、电池框架和汽车保险杠。

为您量身定制 指挥.

凭借我们扎实的制造技术,您可以根据自己的生产要求决定生产数量和其他步骤。

快速原型制作

小批量生产

大批量生产

航空航天制造能力

从原型设计和设计验证到功能测试和产品发布,我们的专业制造服务贯穿整个生产周期。我们以快速的周转和低廉的成本提供高质量、高精度、适于飞行的部件。凭借我们的质量控制流程,您一定能获得符合您独特要求的部件。

实实在在的人,随时准备提供帮助。

即使在订单完成后,我们也会提供卓越的支持,让您有信心将产品推向市场。拥有十多年行业经验和丰富产品专业知识的专业技术人员将协助您排除故障并优化产品使用。

技术支持

项目管理