数控车削服务

At GCH, we offer efficient CNC turning services that cater to all your needs, from rapid prototyping to large production runs. Ensure you receive high-quality CNC-turned parts equipped with the precise features you require, all at competitive pricing and swift lead times.

- 0.02 mm Tight Tolerance

- 交付时间最快 3-5 天

- Automatic DFM Report

30t-1800t

即时报价

12

表面处理

0 件

订购数量

0.025 毫米

公差

Our CNC Turning Services

Take advantage of the on-demand CNC turning service and get reliable metal and plastic turned parts for your unique projects. With advanced technologies and expert technicians, GCH produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities allow us to deliver turned parts with high accuracy, regardless of the complexity. You will get durable parts from flats to radial and axial holes, slots, and grooves as fast as one day.

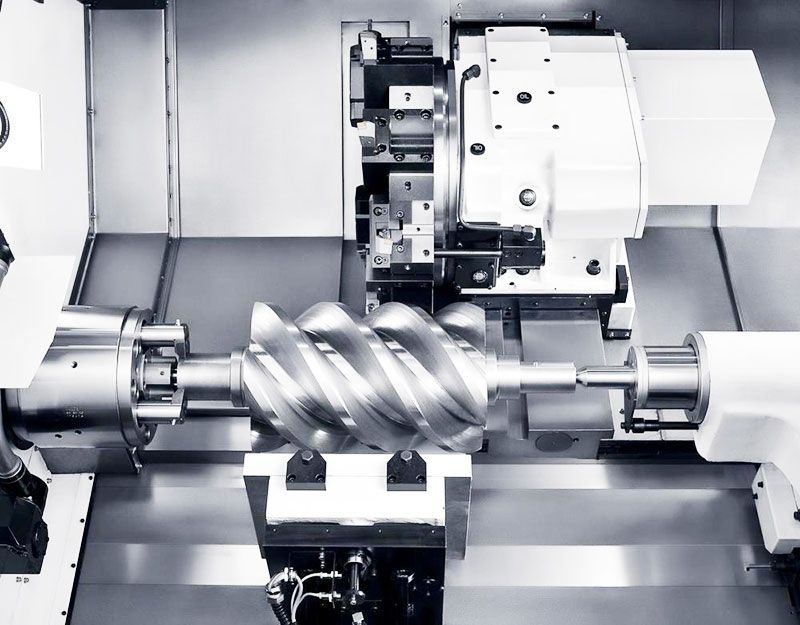

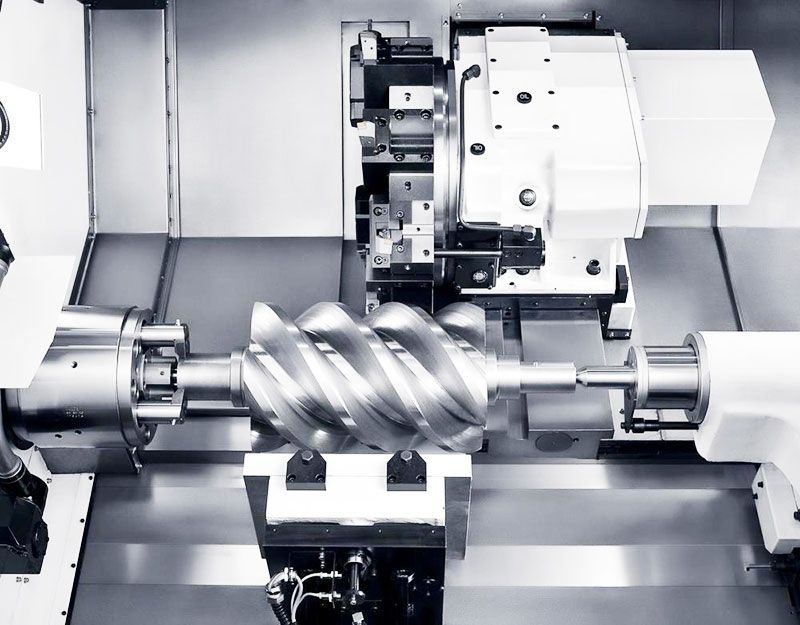

CNC Lathes

Our precision CNC turning lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats. Full automation of these versatile machines allows us to produce hundreds of similar dimensions easier, faster, and cost-effectively.

Gallery of CNC Turning Parts

Why Choose Our CNC Turning Services

GHC is your leading CNC turning company, consistently delivering highly reliable CNC turning services for several industries. Our com

高精度和小公差

快速原型和生产

我们加快您从原型设计到生产的产品开发过程。我们的快速周转可将设计转化为原型,从而加快迭代速度,缩短产品上市时间。我们的数控加工可扩展至任何产量。

先进制造设施

在 GCH,我们的综合设备包括精密 CNC 铣削、车削和电火花加工。从原型到批量生产,我们采用最先进的材料和技术。我们的专业技术人员孜孜不倦地追求最佳产品质量。

通过 IATF16949:2016 认证

GCH 拥有专业的工程师,随时准备优化您的设计、降低成本并提高质量。请相信我们的团队,他们将为您提供卓越的建议和无与伦比的工程支持,确保项目取得一流的成果。

从原型设计到生产

CNC turning is a highly precise and adaptable manufacturing process that utilizes computer-controlled lathes to shape and refine components, making it ideal for rapid prototyping and on-demand production. At GCH, we offer specialized CNC turning services tailored to meet the unique needs of various industries.

快速原型制作

Quickly transform your CAD designs into final CNC-turned prototypes with GCH. Test and refine your concepts, minimize costly turning errors, and accelerate your product’s time-to-market with our precision turning services.

Bridge Production

With GCH’s Bridge Production, smoothly transition from prototype to full-scale CNC turning production. Our process ensures consistent quality, mitigates risks associated with scaling, and delivers precision at every stage of your project.

想要将您的设计变为现实?

开始吧

今日新项目

请立即联系我们的工程师,我们将根据您的需求迅速帮助您确定最佳解决方案。

CNC Truning Tolerances

GCH is dedicated to delivering precision with our CNC turning tolerance standards. We commit to exact measurements, ensuring clients receive consistent, high-quality results optimized for search visibility. Our standard tolerances for CNC-turned metals adhere to ISO 2768-m, and for plastics, we follow ISO 2768-c.

| 类型 | 宽容 |

| 线性维度 | +/- 0.025 毫米 +/- 0.001 英寸 |

| 孔径(未扩孔) | +/- 0.025 毫米 +/- 0.001 英寸 |

| 轴直径 | +/- 0.025 毫米 +/- 0.001 英寸 |

| 部件尺寸限制 | 950 * 550 * 480 毫米 37.0 * 21.5 * 18.5 英寸 |

Materials for CNC Truning Parts

At GCH, our CNC turning service offers a wide range of materials, ensuring precision and durability. This extensive selection provides our clients with the best options for their unique projects, enhancing product quality and performance.

铝质

铝这种金属具有出色的强度重量比。对于飞机托架和外壳的高负载要求来说,铝是一个不错的选择。铝还具有良好的延展性、刚度、耐腐蚀性和可加工性。其轻质特性使其适用于机身蒙皮、机翼弦杆、机翼蒙皮等航空结构应用。

价格 $

交货时间: < 10 天

公差: ±0.125毫米(±0.005英寸)

最大零件尺寸: 200 x 80 x 100 厘米

钛

钛具有多种材料特性,是高要求应用领域的理想金属。这些特性包括出色的耐腐蚀性、耐化学性和耐极端温度性。此外,钛还具有出色的强度重量比。

这些特性使钛合金成为机身和飞机发动机的最佳选择。

价格 $$$

交货时间: < 10 天

壁厚 0.75 毫米

公差: ±0.125毫米(±0.005英寸)

最大零件尺寸: 200 x 80 x 100 厘米

不锈钢

钢是另一种可用于生产现代汽车零部件的金属。这种金属经久耐用,性能高效。它还有利于生产高质量的零件。它耐腐蚀、重量轻,能生产出美观的零件。这种金属可用于生产汽车制动器、发动机、排气系统、车轮等。

价格 $

交货时间: < 10 天

壁厚 0.75 毫米

公差: ±0.125毫米(±0.005英寸)

最大零件尺寸: 200 x 80 x 100 厘米

铜

铜在汽车工业的舒适性、效率和安全性方面发挥着巨大作用。铜是一种优良的导电体,具有很高的延展性和可塑性。它适用于汽车的大部分电子元件,包括汽车线束、散热器、启动电机、交流发电机和制动管。

价格 $

交货时间: <10天

公差: ±0.125毫米

最大部件尺寸: 200 x 80 x 100 厘米

镁

镁重量轻,具有出色的可铸造性和较高的比强度,因此可用于汽车行业。镁可用于生产发动机缸体、变速箱、离合器壳体、车轮和发动机支架以及油盘。

价格 $

准备时间 <10天

公差: ±0.125毫米

最大部件尺寸: 200 x 80 x 100 厘米

为什么选择 GCH

我们采取的方法旨在满足您的定制需求。我们旨在为工程专家和项目经理提供从设计到生产的长期原型包胶解决方案。GCH 将具有成本效益的模具与技术驱动的包覆成型服务相结合,有助于制造出高质量的零件。

无起订量

无最低订货量要求,有助于将塑料成型件从设计到生产的快速周转,并支持按需成型制造需求,降低注塑成型成本。

公差小、质量高

我们的注塑成型工艺包括重要的设计考虑因素,以提高成型性和美观性。GCH 可提供不同尺寸和复杂程度的注塑成型零件。我们的标准公差由 ISO 2768 标准规定,有助于我们满足严格的公差要求。

高效率

我们拥有经过认证的国内工厂和强大的供应链系统,能够加快产品开发周期,并为您尽快生产注塑件架起桥梁。

注塑成型专家

与我们在注塑行业拥有 10 多年经验的专家合作,高效地完成从原型设计到生产的周转。

How Custom CNC Truning Works?

The CNC turning process begins by feeding raw materials such as metals or plastics into a CNC lathe. The machine then spins the material while precision cutting tools shape it into the desired form. Upon completion, the finished component is removed, ready for further use or assembly in production-grade applications.

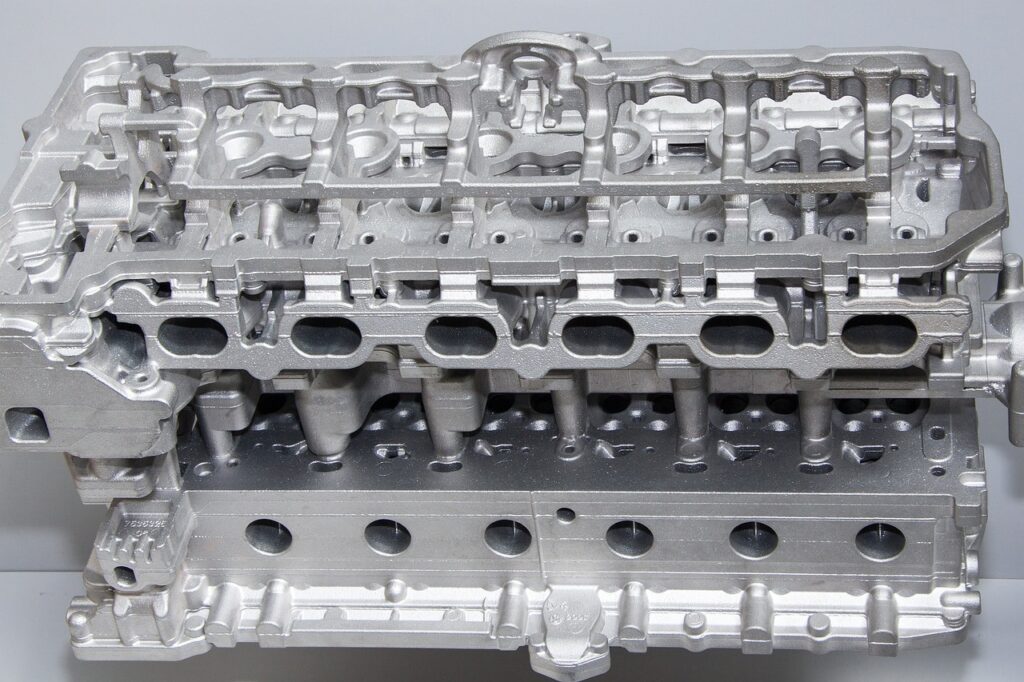

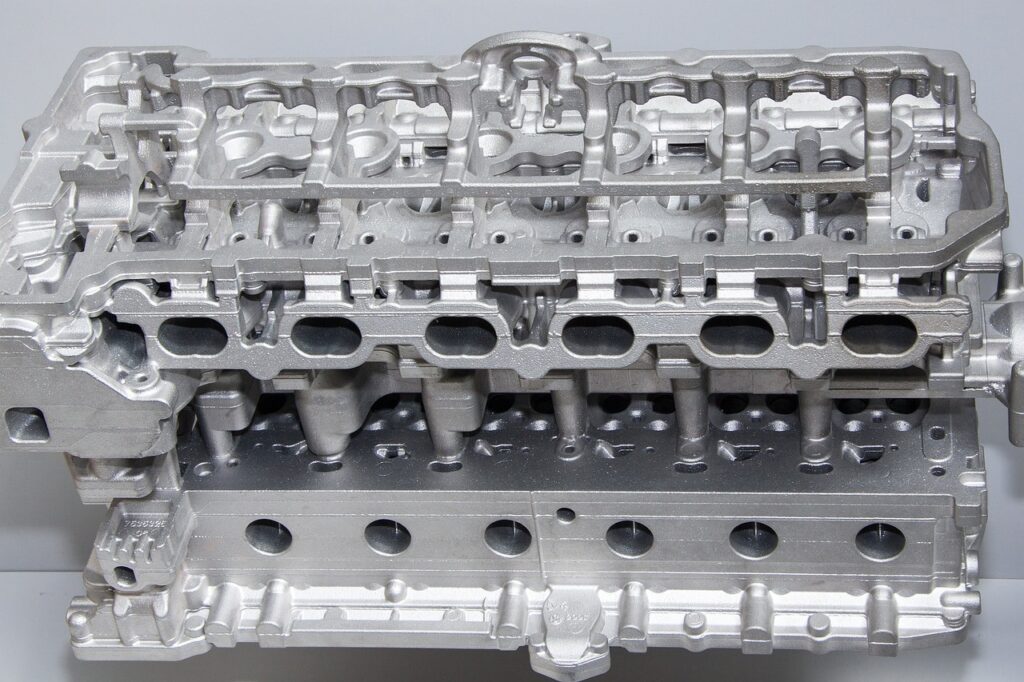

CNC Turning for Various Applications

Dive into GCH’s extensive gallery showcasing some of our completed CNC-turned parts. See firsthand the precision and quality of our work, and feel confident that we can produce your CNC turning project to meet your strict specifications.

常见问题

常见问题

The CNC turning process is mostly ideal for cylindrical-shaped raw materials. However, several manufacturers also use it for hexagonal and square-shaped workpieces. It is a popular method for making machine parts for microfluidic tools, signage components, surgical instruments, automotive frames, and aerospace parts.

We can turn parts with diameters ranging from 0.5mm to 65mm for stock bars. Our turning capabilities can reach up to 3000 mm for billets.

Yes, our CNC turning services include plastic parts manufacturing. We can produce small or large batch prototypes and production parts from various engineering-grade plastics. Choose from our extensive range of plastic materials and upload your design file to get custom plastic components.

The major difference between CNC milling and CNC lathe is in their machining process. CNC milling involves rotating the cutting tools against a stationary bar stock or workpiece. In contrast, a CNC lather works by rotating the bar stock or workpiece against a stationary tool. CNC milling is more suitable for machining irregular and flat surfaces, while CNC lathes work best for cylindrical or conical parts.

最新文章

Top Materials Used In CNC Machining: A Comprehensive Guide

Precision CNC machining services for high-quality, custom parts. Expert manufacturing for industrial applications.

The Latest Trends In CNC Machining Technology You Should Know

“Precision CNC machining manufacturer offering high-quality custom parts, rapid prototypes, and production services for aerospace, automotive, medical, and industrial applications.”

Navigating the Precision Frontier: CNC Machining Trends Shaping 2025

Computer Numerical Control (CNC) machining stands as a cornerstone of modern manufacturing, underpinning the production