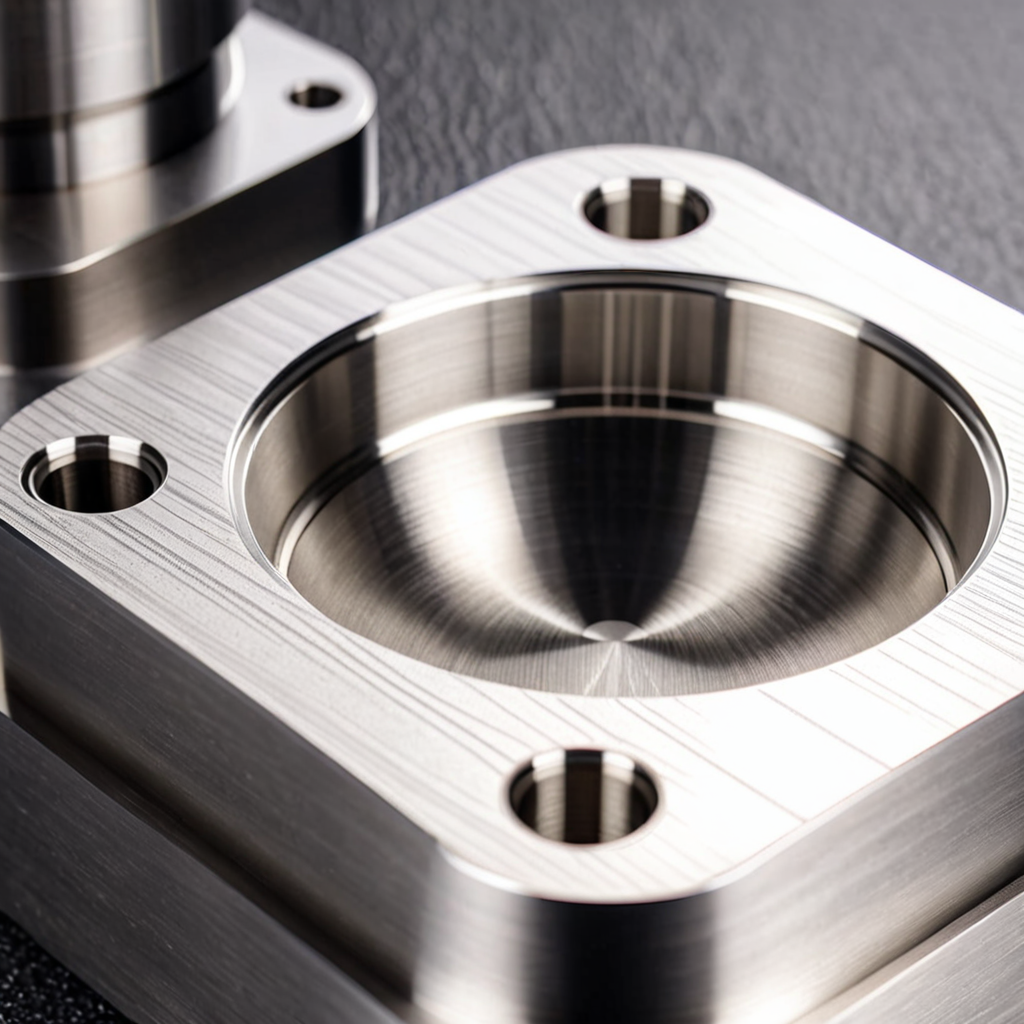

GCH Process excels in providing custom CNC machining parts for engineers, product developers, and designers through a comprehensive network of vetted suppliers. Our AS9100D-certified machine shops are equipped to handle any design, simple or intricate. We offer services ranging from rapid machining and small-batch production to high-volume manufacturing, all managed seamlessly from start to finish. Upload your CAD file to our Instant Quoting Engine℠ for immediate pricing, lead times, and design-for-manufacturability feedback on your custom CNC parts. Our capabilities include machining both metals and plastics with production and shipping options tailored to meet your specific needs and development stage.

Quality Assurance and Certifications

At GCH Process, quality is paramount. We adhere to certified quality management systems, including ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D. We are also ITAR registered. Our quality assurance services include inspections, hardware traceability, material certifications, and Certificates of Conformance (CoCs). With dedicated support teams, we ensure timely delivery of high-quality custom CNC machining parts.

Understanding CNC Machining

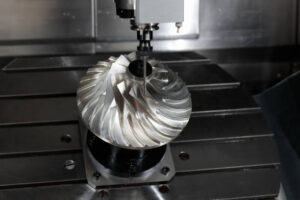

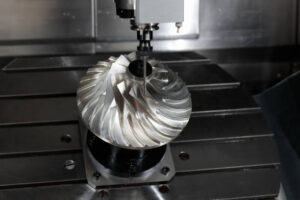

CNC, or computer numerical control machining, automates high-speed cutting tools to shape designs from metal or plastic stock. Common CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. Depending on the process, the workpiece may stay stationary while the tool moves, the tool may stay stationary while the workpiece moves, or both may move simultaneously.

Machinists operate CNC machines by programming tool paths based on the geometry of the final parts, as provided by a CAD model. CNC machines can precisely cut almost any metal alloy and rigid plastic, making custom CNC machining parts ideal for industries like aerospace, medical, robotics, electronics, and industrial applications. GCH Process provides custom CNC quotes for over 40 materials, including aluminum, stainless steel, titanium, PEEK, and Teflon.

Custom CNC Machining Services

定制数控铣削服务

GCH Process offers rapid production of CNC milled prototypes and parts, certified to AS9100D, ISO 9001:2015, ISO 13485, and IATF 16949:2016 standards. Free standard shipping is available on all US orders.

Custom CNC Turning Service

We swiftly deliver CNC turned prototypes and parts, maintaining the same high standards and shipping benefits as our milling services.

Custom CNC Routing Services

Receive quick-turn prototypes and production parts with our Online CNC Routing Service, offering free standard shipping on all US orders.

High Volume Custom CNC Machining Parts

GCH Process efficiently handles high-volume custom CNC machining parts, backed by comprehensive certifications and free standard shipping on all US orders.

What We Guarantee

- 质量保证: Our rigorous quality management system ensures every part meets stringent standards.

- On-Time Delivery: We offer reliable delivery times with expedited shipping options.

- 全面支持: Our support teams assist throughout the process, from initial design to final delivery.

- Flexibility: We provide flexible production options for prototypes or large-scale production runs.

- Transparency: Our Instant Quoting Engine℠ offers clear pricing, lead times, and manufacturability feedback.

常见问题

What materials can GCH Process machine?

We can machine a diverse range of materials, including aluminum, stainless steel, titanium, PEEK, Teflon, and more.

How do I get a quote for my custom CNC machining parts?

Upload your CAD file to our Instant Quoting Engine℠ for pricing, lead time, and manufacturability feedback.

What are the typical lead times for custom CNC machining parts?

Lead times vary based on part complexity and quantity. Our Instant Quoting Engine℠ provides an estimated lead time with your quote.

Can you handle complex geometries and tight tolerances?

Yes, our advanced CNC capabilities and skilled machinists can handle complex geometries and tight tolerances.

What quality certifications do you have?

Our quality management system is certified to ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D. We are also ITAR registered.

CNC Machining Process Steps

- Design Upload: Submit your CAD model via our Instant Quoting Engine℠.

- Quote Generation: Receive an instant quote with pricing, lead time, and manufacturability feedback.

- Order Placement: Confirm your order and provide any additional specifications.

- Production: Certified machine shops manufacture your custom CNC parts with precision.

- 质量保证: Thorough inspections ensure parts meet your specifications.

- Shipping: Parts are shipped with free standard shipping on all US orders.

Experience the precision, reliability, and quality of GCH Process for all your custom CNC machining parts needs.