了解数控加工工艺及其成本

数控加工 is an essential manufacturing process across various industries, including automotive, aerospace, and construction. It enables the creation of a wide range of products, from car chassis and surgical equipment to aircraft engines. This process utilizes several techniques to shape custom parts or products by removing material from the workpiece. Below are the most common CNC machining operations, along with their costs and considerations.

I. CNC Drilling

CNC drilling involves advancing a rotary drill bit perpendicular to the workpiece surface to produce vertically aligned holes. The diameter of these holes matches that of the drill bit. Drilling capabilities include counterboring, reaming, and tapping. The cost of CNC drilling depends on factors such as material type, hole size, and complexity of the drilling pattern.

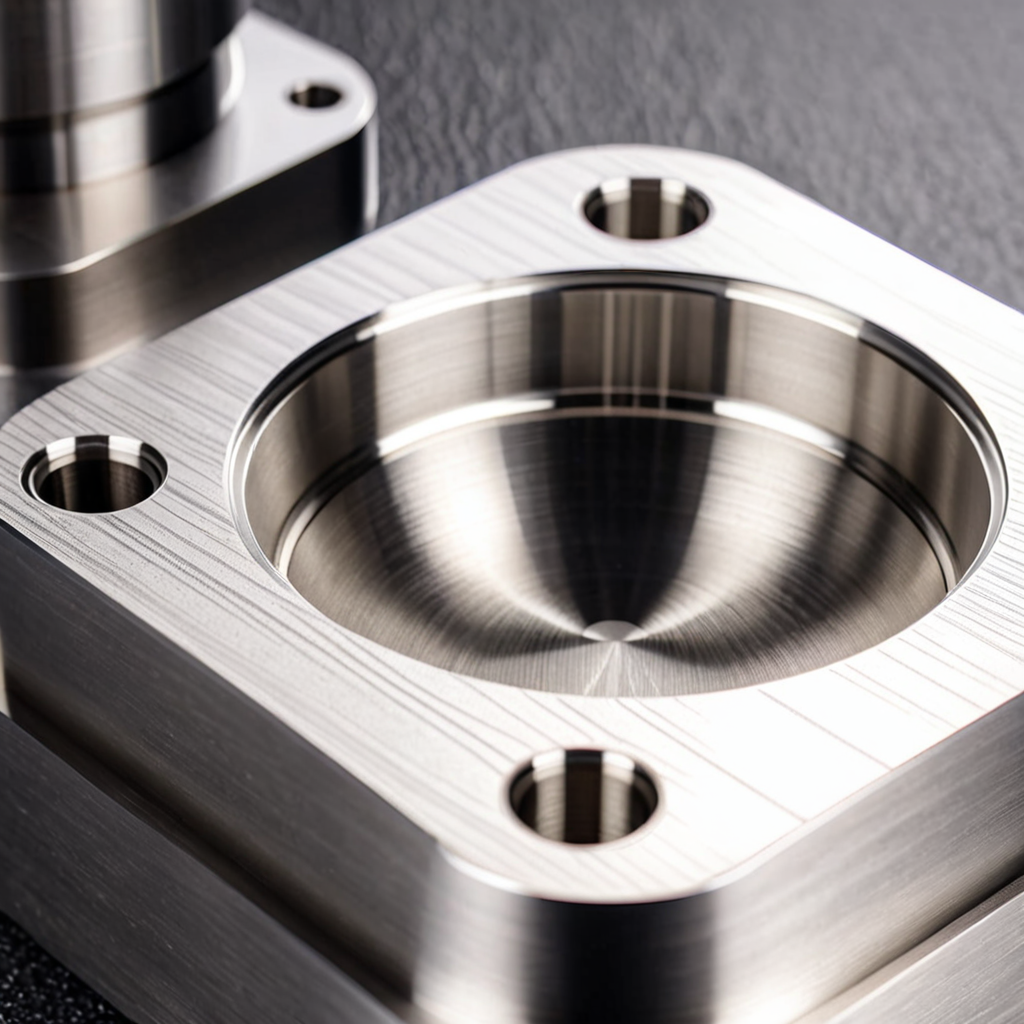

II. CNC Milling

CNC milling is where the CNC machine feeds the workpiece in the same direction as the cutting tool’s rotation. This differs from manual milling, where the workpiece moves opposite to the tool’s rotation. Milling operations include:

- Face Milling: Cuts flat, shallow surfaces and flat-bottomed cavities.

- Peripheral Milling: Cuts deep cavities such as slots and threads.

The cost of CNC milling is influenced by the material’s machinability, the complexity of the design, and the precision required. Milling often involves significant setup and tooling costs, making it suitable for both prototypes and production runs.

III. CNC Turning

In CNC turning, the machine feeds the cutting tool in a linear motion along the rotating workpiece’s surface, removing material around the circumference until the desired diameter is achieved. This process is ideal for shaping cylindrical parts with features like slots, cones, and threads. The turning process includes boring, facing, grooving, and threading. CNC turning costs are affected by the material, part complexity, and required tolerances.

IV. Electrical Discharge Machining (EDM)

EDM shapes parts using electric sparks. Current discharges between two electrodes, removing material from the workpiece. When the gap between electrodes narrows, the electric field strength causes a current flow, discharging material from both electrodes. EDM is particularly useful for hard metals and complex shapes. The cost of EDM is higher than traditional machining due to its slower process and the need for specialized equipment.

Selecting Materials for CNC Machining

CNC machining works with various materials, including metals, plastics, and composites. The choice of material significantly impacts the machining cost, determined by factors such as material properties and specifications.

CNC Metals

Metals are often chosen for their strength, hardness, and thermal resistance. Common CNC metals include:

- 铝 Ideal for custom parts and prototypes.

- 不锈钢: Easily welded, machined, and polished.

- Mild Steel: Used for machine parts, jigs, and fixtures.

- Alloy Steel: Improved hardness, toughness, and wear resistance.

- 工具钢: Suitable for dies, stamps, and molds.

- Brass: Low friction, often used for aesthetic purposes.

CNC Plastics

Plastics are valued for their lightweight and diverse properties:

- ABS: Common for prototypes before mass production.

- Nylon (PA): Known for mechanical properties, impact strength, and chemical resistance.

- Polycarbonate: Optically transparent, used in fluid devices and automotive glazing.

- POM (Delrin): Chosen for high precision, rigidity, and dimensional stability.

- PTFE (Teflon): Excellent electrical insulator and temperature resistance.

- HDPE: Suitable for outdoor use and piping.

- PEEK: High strength-to-weight ratio, suitable for medical and engineering applications.

CNC Composite Materials

Composites combine materials with different properties to create stronger, lighter, or more flexible products. Common composites include:

- Reinforced Plastic: Uses fibers like carbon or fiberglass to enhance strength and versatility.

- Carbon Fiber: Conductive, high modulus, and tensile strength, excellent for high-temperature resistance.

- Fiberglass: Nonconductive, ideal for electrical or broadcast applications.

- Resins: Hold materials together in composites, providing strength and flexibility.

Industries Utilizing CNC Machining

CNC machining is pivotal across various sectors, each with unique requirements:

航空航天工业

CNC machining is essential for high-tolerance, complex geometries, and advanced materials. Companies like Boeing and Airbus leverage composites for lighter, fuel-efficient aircraft, reducing CO2 emissions and meeting regulatory standards.

Medical Industry

The medical sector relies on precision and speed for customized devices. CNC machining produces implants, orthoses, MRI machines, and surgical instruments. Companies like Galen Robotics use CNC machining to develop precision tools for non-invasive surgery.

Transportation Industry

The transportation sector demands durable and robust components. CNC machining creates parts for high-speed trains, brakes, engine parts, and tools, ensuring precision and longevity.

Oil and Gas Industry

Petrochemical applications require precisely machined parts for large machines in refineries and drilling platforms. Components must withstand harsh environments, making CNC machining crucial for reliability and performance.

Military and Defense Industry

Military applications demand robust, regulation-compliant parts. CNC machining produces pins, casings, artillery, and aircraft components. The defense sector frequently updates CNC technology to maintain cutting-edge capabilities.

电子行业

Electronics manufacturing relies on CNC machining for small, precise components. This includes custom enclosures, printed circuit boards, and smartphone casings. CNC machining offers high precision without chemical processes, enhancing efficiency.

Maritime Industry

Marine components must be water-resistant and durable. CNC machining creates parts for electrical devices, ship components, and anti-torpedo systems, ensuring longevity and resistance to corrosion.

Market Trends and Challenges in CNC Machining

The global CNC machining market was valued at $67.78 billion in 2019 and is projected to reach $103.43 billion by 2025. Key trends include:

Factory Automation

Automation enhances speed and accuracy, reducing production time and minimizing errors. Companies invest in R&D to improve tool design and integrate IoT for real-time machine status monitoring.

New Technologies

The automotive industry adopts IoT, AI, Machine Learning, and Robotics for efficient production. Innovations like self-calibrating CNC machines enhance productivity and reduce setup times.

Renewable Energy Production

CNC machining supports renewable energy systems, aiding in the creation of solar panels, wind turbines, and other alternative energy sources. Companies like ANCA leverage renewable energy for cost savings and environmental benefits.

结论

CNC machining is a versatile and essential manufacturing process across multiple industries. Understanding the costs associated with different CNC processes, material choices, and market trends helps businesses optimize their production and stay competitive. For precise, high-quality machining services, consider partnering with GCH, known for their expertise and commitment to excellence.