Rapid prototyping serves as a foundational strategy in contemporary product development, revolutionizing the way teams iterate and validate design concepts prior to full-scale manufacturing. This methodology involves the creation of 3-dimensional prototypes that closely emulate the final product, allowing for thorough testing and refinement of critical attributes such as form, functionality, and user experience.

Understanding the Essence of Rapid Prototyping

At its core, 快速成型 empowers product teams to swiftly generate iterative prototypes based on real-time user feedback and data-driven analysis. Unlike traditional manufacturing processes that necessitate significant time and resources to produce physical models, 快速成型 expedites the validation cycle, ensuring that product designs align closely with market demands from the outset.

Operational Mechanisms of Rapid Prototyping

The operational framework of 快速成型 revolves around the agile creation of prototypes that closely mirror the envisioned end product. By soliciting early feedback from users engaging with these prototypes, product teams can validate assumptions and detect potential design flaws in the nascent stages of development. This iterative approach mitigates the risk of delivering products that fail to meet user expectations and accelerates the pathway to market readiness.

Advanced Techniques in Rapid Prototyping

Diverse techniques augment the efficacy of 快速成型, ranging from high-fidelity simulations to foundational wireframe models. High-fidelity prototypes simulate real-world interactions with precision, integrating actual data and functionalities to provide comprehensive insights into user behavior and preferences. Conversely, wireframes serve as preliminary models to conceptualize workflow and fundamental UX principles, ideal for initial validation and iterative refinement phases.

Strategic Importance for Product Managers

For product managers, 快速成型 confers a strategic advantage by mitigating risks associated with unproven concepts and features. By engaging real users early in the development lifecycle, managers can validate product hypotheses and prioritize features based on direct user feedback. This proactive approach accelerates time-to-market and ensures that final products resonate authentically with end-user needs and expectations.

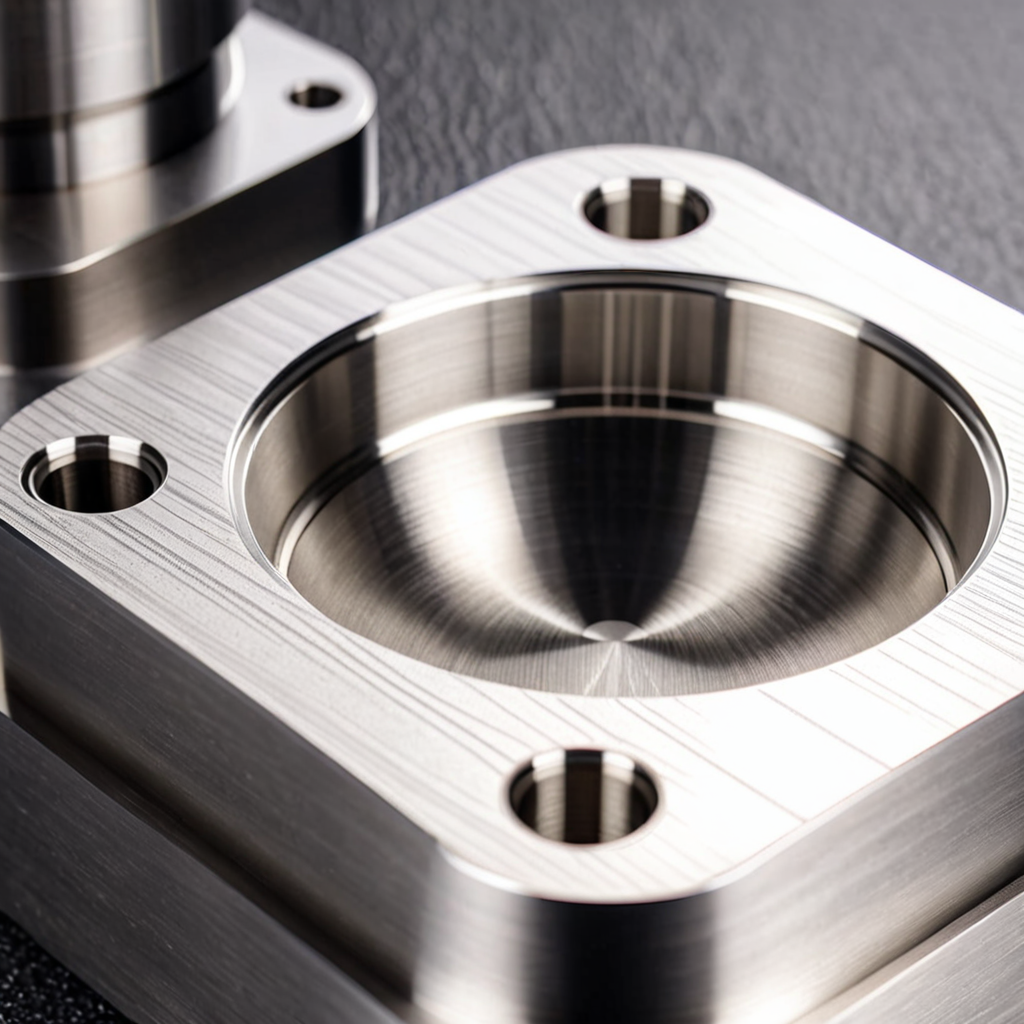

GCH Process: Leading the Way in Rapid Prototyping Services

At GCH, our proprietary 快速成型服务 process stands at the forefront of innovation. Leveraging advanced technologies and industry expertise, we streamline prototyping timelines and enhance product quality. Our commitment to iterative refinement and user-centric design ensures that every prototype not only meets but exceeds market expectations. By integrating GCH 流程 into your product development cycle, you can navigate complex design challenges with confidence, delivering superior products to market swiftly and effectively.

结论

In conclusion, 快速成型 emerges as a pivotal methodology in modern product development, fostering innovation and operational efficiency. By embracing 快速成型, product teams navigate complex design challenges with agility, ensuring that final products meet the highest standards of usability and functionality. This iterative process enhances product quality, reduces development costs, and expedites innovation cycles, ultimately delivering superior products to market.