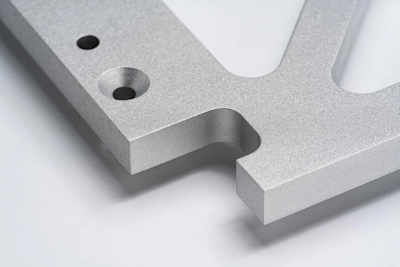

In today’s competitive manufacturing industry, precision CNC turning services have become one of the core technologies for achieving high-precision component machining. Whether it’s small electronic components or complex parts in aerospace, CNC turning can meet the extremely high demands for detail and accuracy in manufacturing.

Advantages of CNC Turning

High Precision and Consistency

The greatest advantage of CNC turning is its ability to ensure that each part has extremely high precision, with errors typically controlled within ±0.001 inches. This is crucial for industries with strict part accuracy requirements, such as aerospace and medical devices.

提高生产效率

Automated CNC systems mean continuous operation around the clock, significantly increasing production efficiency. With multi-axis CNC turning, parts can be machined in multiple steps in one setup, reducing operation time and manual intervention.

Strong Adaptability

CNC turning can handle a variety of metal materials, such as aluminum, stainless steel, and titanium, as well as plastics and composite materials. Whether it’s small-batch custom CNC turning or mass production, CNC technology can flexibly respond.

Cost Control

Although the initial investment in CNC equipment is relatively high, its efficient machining capabilities and precision can significantly reduce waste and scrap rates in production, thereby controlling overall manufacturing costs.

What is CNC Turning?

In simple terms, CNC turning is a machining method that removes material by controlling the lathe with a computer system. Unlike traditional manual turning, 数控车削服务 allow cutting tools to move on multiple axes, which not only enhances the precision of part machining but also greatly improves production efficiency. This technology is particularly suitable for machining shafts or round parts that require high precision, such as automotive parts, aircraft components, and miniature parts in electronic devices.

Industries of Application

汽车行业

In the automotive industry, CNC turning is widely used for manufacturing engine components, transmission parts, and various complex shaft parts. Since automotive parts need to work under high temperatures and pressures, CNC lathe services ensure the durability and precision of these parts.

Aerospace Field

Components of aircraft and spacecraft often require extremely high precision, and even minor errors can lead to serious safety issues. CNC turning not only can manufacture complex geometric shapes but also ensures that each CNC turning part meets strict quality standards.

Medical Equipment

For the medical industry, safety and precision are paramount. Precision CNC turning has unparalleled advantages in manufacturing high-precision medical devices, surgical tools, and implants.

电子行业

CNC turning technology also occupies an important position in the electronics industry. Many small and complex electronic components require CNC turning processing, such as heat sinks and connectors.

GCH Process: Expert in CNC Turning

As a leading CNC machining company in the industry, GCH Process not only has the most advanced CNC equipment but also has a team of experienced engineers. We can handle various complex part machining needs, covering 数控车削服务 from 3-axis to 5-axis, ensuring that each part meets the highest precision standards.

We understand the unique needs of different projects, so we provide customized solutions. Whether it’s small-batch prototype processing or mass production, GCH Process always focuses on the customer, ensuring that every order is delivered on time and meets strict quality requirements. With our advanced equipment and meticulous quality control, we have become the preferred CNC machining supplier for many industries worldwide.

Future Development Trends

With the continuous advancement of technology, 数控车削服务 are moving towards a more intelligent and precise direction. The introduction of artificial intelligence and machine learning will further improve machining efficiency and precision. In addition, the promotion of green manufacturing concepts has also prompted CNC turning technology to continuously innovate in terms of energy efficiency and material utilization.

结论

数控车削服务 provide unprecedented flexibility and precision for modern manufacturing. Whether in the automotive, aerospace, or electronics and medical equipment fields, CNC turning provides an ideal solution for manufacturing complex and high-precision parts. For any company looking to enhance product quality through precision manufacturing, choosing 数控车削服务 is undoubtedly a wise decision. With the continuous advancement of technology, we can expect CNC turning to play a more significant role in a broader range of fields in the future, promoting the manufacturing industry towards a more efficient and precise direction.