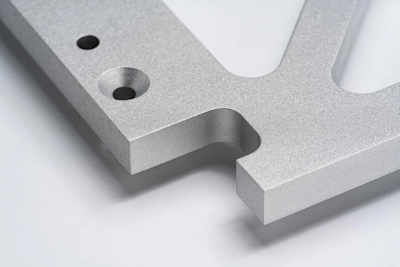

在制造业中,CNC(计算机数控)机床是简化定制零件生产流程的宝贵工具。虽然许多爱好者的车库里都有小型数控机床,但对于更大、更复杂的项目,往往需要求助于像 GCH 这样的专业服务机构。在本文中,我们将探讨以下影响因素 数控铣削成本 以及您在下一个项目中应该考虑的事项。

影响数控铣削成本的关键因素

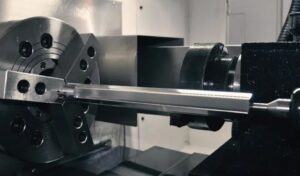

1.机器尺寸: 数控机床的尺寸对其成本影响很大。小型台式数控铣床的成本远远低于工作包络面为 5'x5'x5' 的大型铣床。大型机床需要更多的材料和部件,这就增加了制造的复杂性和成本。所需零件的尺寸将决定所需的机床尺寸。

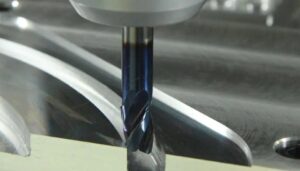

2.机器的复杂性: 具有多轴运动和自动化功能的高级数控机床价格更高。例如,配有 20 位自动换刀装置的机床可提供极大的便利,但也增加了总成本。

3.机器精度: 提供高精度和高准确度的机床价格不菲。业余数控机床的精度可能达到 +/- 0.010",而公差为 +/- 0.0003 "或更高的工业机床的价格则要高得多,这通常是出于精密工程的需要。

4.机器速度: 配备大功率电机和强大控制系统的高速数控机床成本较高。尽管初始投资较高,但这些机器往往能提高生产率,随着时间的推移,有可能抵消额外的成本。

5.材料兼容性: 能够加工各种材料(金属、塑料、木材)的机器通常比仅限于加工特定材料的机器更昂贵。

6.品牌和声誉: 知名品牌因其公认的可靠性和支持而价格较高。投资知名品牌可以让您高枕无忧,而且往往具有更高的转售价值。

7.附加功能 自动换刀装置、冷却系统和专用软件等可选附加功能会增加成本。这些功能虽然增加了成本,但往往能提高效率和精度。

数控机床的类型及其成本

不同的数控机床根据其功能和应用的不同,成本也各不相同:

- 入门级台式数控铣床: $150 – $500

- 业余级数控铣床: $1,000 – $3,000

- 业余级 CO2 激光器: $1,000 – $3,000

- 小型企业等离子桌: $1,000 – $5,000

- 专业数控机床: $50,000 – $100,000

- 入门级三轴铣床: $50,000 – $100,000

- 工业用高清等离子台: $40,000 – $120,000

- 工业光纤激光器: $100,000 - 超过 $500,000

- 生产型三轴数控铣床: $100,000 – $500,000

- 生产型 5 轴数控铣床: 超过 $500,000

这些机器的价格反映了尺寸、功率、切割速度、精度和附加功能等因素。

数控铣削的额外成本

除了机器本身,还应考虑其他一些成本:

- 工具和配件: 这些工具可能包括润滑剂、冷却剂、麻花钻、铣床和测量工具。

- 人员配备和培训: 操作员的工资和培训费用也应考虑在内。

- 维护和修理: 定期维护对机器的使用寿命和性能至关重要。

- 软件 确保与现有系统的兼容性以及必要的软件许可证费用。

应该购买还是外包?

对于许多小型企业来说,将数控铣床外包给 GCH 这样的专业供应商比购买一台机床更经济。外包无需大量的资本投资和持续维护。GCH 提供一系列数控铣削服务,能够高效处理复杂和大批量的项目。

购买二手数控机床

购买二手数控机床是一种具有成本效益的选择,尤其是对于超过 $10,000 的机床而言。MachineTools 等网站提供了一个买卖二手机械的市场。在购买二手设备时,彻底的检查和评估对确保您的投资是正确的至关重要。

结论

了解与数控铣床相关的成本对于做出明智的决策至关重要。通过考虑机床尺寸、复杂性、精度、速度、材料兼容性、品牌声誉和附加功能,您可以更好地衡量所需投资。无论您是决定购买一台数控机床,还是外包给 GCH 这样的专业服务公司,评估这些因素都将帮助您实现制造需求的最佳效果。

如需数控铣削项目的进一步帮助,请访问 GCH 网站,了解我们的服务并获得即时报价。