The automotive industry is in the midst of a revolution, driven by advancements in technology and the demand for higher performance, safety, and customization. At the heart of this transformation is CNC (Computer Numerical Control) machining, a manufacturing process that has redefined the production of automotive components. Custom CNC automotive parts are now more critical than ever, offering unparalleled precision, versatility, and innovation. In this comprehensive guide, we’ll explore the role of custom CNC automotive parts in modern vehicles, their benefits, applications, and why they are essential for meeting the diverse needs of the automotive industry.

Why Custom CNC Automotive Parts are Essential

1. Meeting Unique Requirements

Every vehicle has specific requirements based on its design, function, and performance goals. Custom CNC automotive parts are tailored to meet these unique needs, ensuring optimal performance and reliability.

2. Precision Engineering

CNC machining guarantees that every part is manufactured with exacting precision. This level of accuracy is crucial for automotive applications, where even minor deviations can compromise safety and performance.

3. 材料多样性

Custom CNC automotive parts can be made from a wide range of materials, including aluminum, steel, titanium, and high-performance plastics. This versatility allows manufacturers to choose the best material for each application.

4. Enhanced Performance

By optimizing designs and materials, custom CNC automotive parts can enhance vehicle performance, whether in terms of speed, fuel efficiency, or durability.

5. 可持续性

CNC machining minimizes material waste and can incorporate recycled materials, making custom automotive parts an eco-friendly option for the automotive industry.

Key Applications of Custom CNC Automotive Parts

1. Engine Components

Custom CNC automotive parts like engine blocks, pistons, and cylinder heads are critical for ensuring the efficiency and reliability of vehicle engines. CNC machining allows for complex geometries and precise tolerances, enhancing engine performance.

2. Transmission Systems

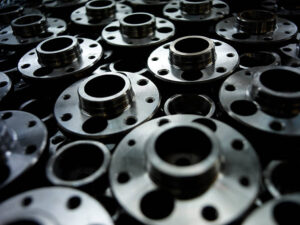

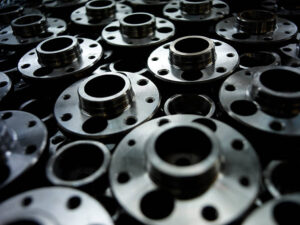

Gears, shafts, and housings for transmissions require high precision and durability. Custom CNC components ensure smooth operation and increased longevity.

3. Suspension and Steering

Custom CNC automotive parts such as control arms, steering knuckles, and shock absorbers are designed to improve vehicle handling and stability.

4. Brake Systems

Brake rotors, calipers, and pads are essential for vehicle safety. Custom CNC machining ensures these components are perfectly balanced and free from defects.

5. Interior and Exterior Parts

Custom CNC automotive parts are used to create personalized interior trim, dashboard components, and exterior body panels, enhancing the aesthetic appeal of vehicles.

6. Electric Vehicle (EV) Components

The rise of electric vehicles has created demand for custom CNC parts such as battery housings, motor mounts, and charging connectors.

Advantages of Custom CNC Automotive Parts

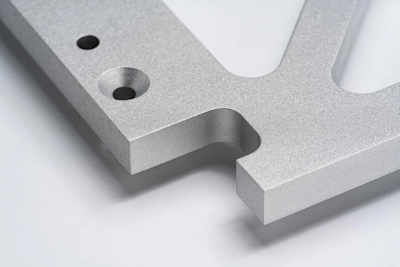

1. Unmatched Precision

CNC machining ensures that every part meets exact specifications, with tolerances as tight as a few micrometers. This precision is essential for the reliable operation of automotive systems.

2. 一致性和可重复性

Custom CNC automotive parts are produced with consistent quality, even in high-volume production runs. This uniformity is crucial for maintaining safety and performance standards.

3. 复杂几何图形

CNC machines can create intricate shapes and designs that are impossible to achieve with traditional manufacturing methods. This capability is particularly valuable for producing complex automotive components.

4. 快速原型和生产

CNC machining allows for quick prototyping and mass production of custom parts. This speed is essential for meeting the fast-paced demands of the automotive industry.

5. Enhanced Surface Finish

CNC machining provides excellent surface finishes, reducing the need for additional post-processing. This not only saves time but also improves the performance and aesthetics of automotive parts.

The CNC Machining Process for Custom Automotive Parts

1. Design and Prototyping

The process begins with CAD (Computer-Aided Design) software, where engineers create detailed 3D models of the custom parts. Prototypes are machined to test the design and make necessary adjustments.

2. 材料选择

The appropriate material is chosen based on the part’s function and requirements. Common materials used in custom CNC automotive parts include aluminum, steel, titanium, and high-performance plastics.

3. 数控铣床

CNC milling is used to create complex shapes and features by removing material from a workpiece. It is ideal for producing components like engine blocks and transmission housings.

4. 数控车削

CNC turning is used for cylindrical parts such as shafts and rods. The workpiece rotates while a cutting tool shapes it to the desired dimensions.

5. Finishing Operations

After machining, custom parts undergo finishing processes such as grinding, polishing, and coating to improve their surface finish and durability.

6. 质量控制

Each part is inspected using advanced measurement tools to ensure it meets the required specifications and tolerances. This step is critical for maintaining the quality and reliability of custom CNC automotive parts.

Choosing the Right CNC Machining Partner for Custom Automotive Parts

Selecting the right CNC machining partner is crucial for achieving high-quality results. Here are some factors to consider:

1. 行业经验

Choose a company with a proven track record in CNC machining automotive parts. Experience in the automotive industry ensures they understand the specific requirements and challenges.

2. Quality Certifications

Ensure the company holds relevant certifications, such as ISO 9001 and IATF 16949, which are specific to the automotive industry.

3. Advanced Technology

The company should use state-of-the-art CNC machines and software to ensure precision and efficiency.

4. Material Expertise

Verify that the company has experience working with the materials required for your custom parts.

5. Turnaround Time

A reliable partner should offer quick turnaround times without compromising on quality.

6. Customer Support

Good communication and support are essential for a smooth collaboration. Choose a company that is responsive and transparent.

Future Trends in Custom CNC Automotive Parts

1. Electric Vehicles (EVs)

The rise of electric vehicles is driving demand for lightweight and high-performance custom CNC parts. Innovations in battery housings, motor mounts, and charging connectors are key areas of focus.

2. 增材制造集成

The combination of CNC machining with additive manufacturing (3D printing) is opening up new possibilities for creating complex and lightweight automotive parts.

3. Smart Factories

The adoption of IoT (Internet of Things) and AI (Artificial Intelligence) in manufacturing is transforming CNC machining. Smart factories enable real-time monitoring and optimization of production processes.

4. Sustainable Practices

Automotive manufacturers are increasingly focusing on sustainability. CNC machining companies are adopting eco-friendly practices, such as recycling materials and reducing energy consumption.

5. Customization and Personalization

As consumer demand for customized vehicles grows, CNC machining will play a key role in producing personalized automotive parts.

Case Studies: Custom CNC Automotive Parts in Action

Case Study 1: High-Performance Engine Pistons

A racing team partnered with a CNC machining company to produce custom aluminum pistons. The precision and durability of the CNC-machined pistons contributed to improved engine performance and reliability.

Case Study 2: Lightweight EV Battery Housings

An electric vehicle manufacturer used CNC machining to produce custom aluminum battery housings. The innovative design reduced vehicle weight while maintaining structural integrity.

Case Study 3: Custom Dashboard Panels

A luxury car manufacturer leveraged CNC machining to produce custom interior dashboard panels. The precision and aesthetics of the CNC-machined parts enhanced the vehicle’s overall appeal.

结论

Custom CNC automotive parts are at the forefront of modern vehicle manufacturing, offering precision, innovation, and performance that are essential for meeting the diverse needs of the automotive industry. From engine components and transmission systems to EV parts and interior trim, CNC machining ensures that every part meets the highest standards of quality and reliability.

As the automotive industry continues to evolve, custom CNC automotive parts will remain a cornerstone of innovation, driving advancements in electric vehicles, sustainability, and customization. By choosing the right CNC machining partner, automotive manufacturers can stay ahead of the competition and deliver superior products to their customers.