导言

Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, offering unparalleled precision and efficiency. As a seasoned 数控加工制造商, GCH has been at the forefront of this technological evolution. This article delves into the history and advancements of CNC machining, highlighting its impact on modern manufacturing.

Early Beginnings

CNC machining traces its origins to the 1940s when John T. Parsons and MIT collaborated to develop a method for creating complex aircraft parts. This innovation laid the groundwork for modern CNC machining, transforming the capabilities of CNC machining manufacturers worldwide.

The Evolution of CNC Technology

The 1950s and 1960s saw significant advancements in CNC technology. The introduction of computerized control systems allowed CNC machining manufacturers to produce parts with unmatched accuracy. By the 1970s, CNC machines were integrated with CAD (Computer-Aided Design) software, further enhancing the precision and efficiency of the manufacturing process.

During these decades, CNC machines evolved from simple punch tape systems to more sophisticated systems using numerical control with computer technology. This transition allowed for greater flexibility and automation, enabling CNC machining manufacturers to produce highly complex geometries and improve overall production capabilities.

The Integration of CNC and CAM

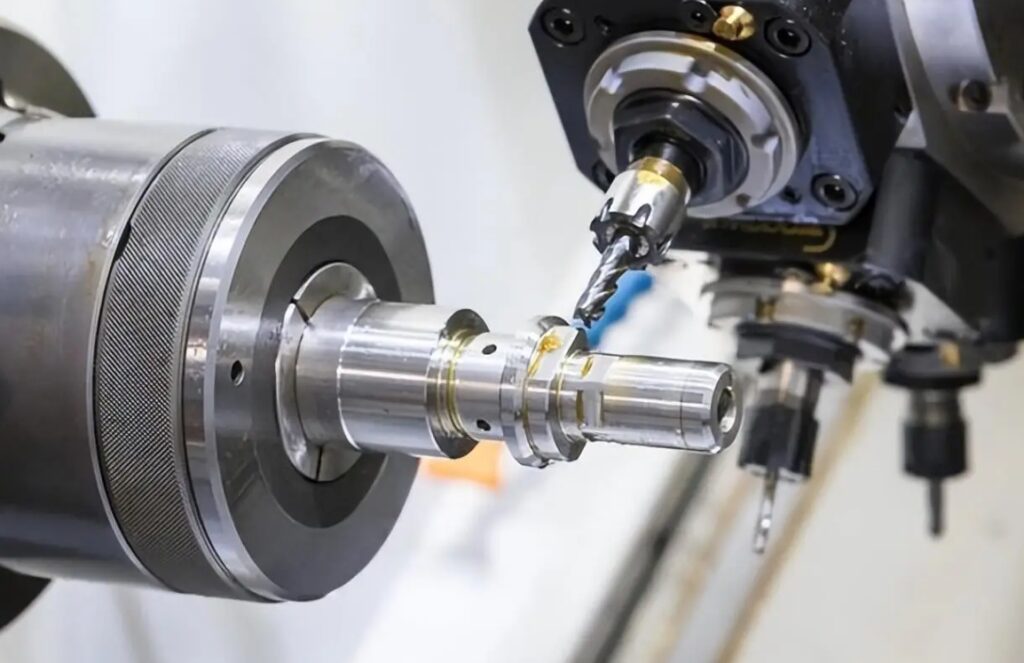

In the 1980s, the integration of Computer-Aided Manufacturing (CAM) with CNC systems marked another significant milestone. This integration allowed for seamless transition from design to manufacturing, enabling CNC machining manufacturers to streamline their operations and reduce lead times. CAM software provided precise toolpath generation and simulation, ensuring optimal machining strategies and minimizing errors.

CNC Machining in the Modern Era

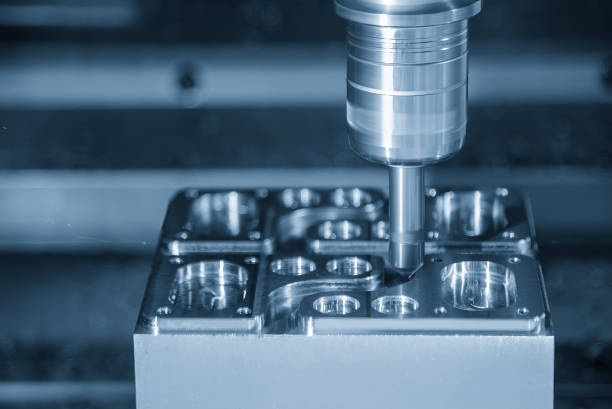

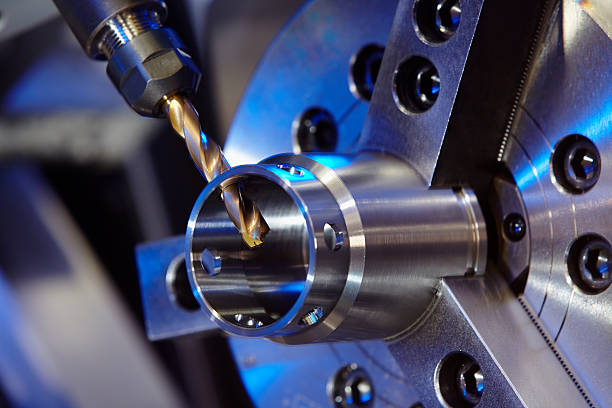

Today, CNC machining manufacturers like GCH utilize state-of-the-art machines to produce complex components for various industries, including automotive, aerospace, medical, and consumer goods. The integration of AI and IoT has further optimized CNC machining processes, enabling real-time monitoring and predictive maintenance.

Modern CNC machines are equipped with multi-axis capabilities, allowing for intricate and detailed workpieces. Five-axis and even seven-axis CNC machines are now common in advanced manufacturing setups, providing unparalleled flexibility and precision. These machines can handle a wide variety of materials, including metals, plastics, ceramics, and composites, meeting the diverse needs of different industries.

数控加工的优势

CNC machining offers numerous advantages, making it the preferred choice for manufacturers:

- 精度和准确性: CNC machines can produce parts with tight tolerances, ensuring high-quality and consistent results. This level of precision is critical for applications where even minor deviations can lead to significant issues, such as in the aerospace or medical device industries.

- Efficiency: Automated CNC machines reduce production time and labor costs, allowing manufacturers to meet tight deadlines. The ability to run machines continuously with minimal supervision increases productivity and profitability.

- 多功能性: CNC machining can handle a wide range of materials, including metals, plastics, and composites, making it suitable for various applications. This versatility allows manufacturers to produce everything from simple components to highly complex parts.

- 重复性: Once a program is created, CNC machines can reproduce the same part with exacting accuracy, ensuring uniformity across production batches.

- Safety: CNC machining reduces the need for manual intervention, minimizing the risk of accidents and ensuring a safer working environment.

GCH: A Leading CNC Machining Manufacturer

As a leading CNC machining manufacturer, GCH is committed to delivering high-quality components that meet the stringent requirements of our clients. Our advanced CNC machines and skilled engineers ensure that every part we produce adheres to the highest standards of precision and durability.

At GCH, we continually invest in the latest CNC technology and training for our staff, ensuring that we stay ahead of industry trends and maintain our reputation for excellence. Our comprehensive quality control processes and certifications guarantee that our products meet or exceed industry standards.

数控加工的应用

The applications of CNC machining are vast and varied, covering numerous industries:

- 汽车: CNC machining is used to produce engine components, transmission parts, and custom car parts with high precision and reliability.

- 航空航天: The aerospace industry relies on CNC machining for critical components such as turbine blades, structural parts, and custom fittings, all requiring the highest levels of accuracy and quality.

- Medical: CNC machining is essential for manufacturing medical devices, surgical instruments, and implants, where precision and consistency are paramount.

- 消费品: From electronics to household appliances, CNC machining plays a crucial role in producing components with intricate designs and tight tolerances.

- Defense: CNC machining is used to create components for military equipment, weapons systems, and other defense-related applications, where durability and precision are critical.

数控加工的未来趋势

The future of CNC machining looks promising, with continuous advancements in technology. CNC machining manufacturers are exploring new materials, such as advanced composites and nanomaterials, to enhance product performance. Additionally, the adoption of green manufacturing practices is becoming increasingly important, with a focus on reducing waste and energy consumption.

Emerging technologies such as additive manufacturing (3D printing) are being integrated with traditional CNC machining to create hybrid manufacturing processes that offer greater design flexibility and efficiency. Moreover, advancements in AI and machine learning are enabling predictive maintenance and smart manufacturing, further optimizing production processes and reducing downtime.

结论

CNC machining has come a long way since its inception, transforming the manufacturing landscape. As a trusted CNC machining manufacturer, GCH remains dedicated to staying at the cutting edge of this technology, providing our clients with innovative and reliable solutions. The ongoing advancements in CNC technology promise to further revolutionize the industry, driving efficiency and precision to new heights.

CNC machining manufacturers like GCH will continue to play a pivotal role in advancing manufacturing capabilities, ensuring that we meet the evolving demands of various industries with precision, reliability, and innovation.