激光切割服务

- 交付时间最快 3-5 天

- 通过 ISO 9001:2015 认证

30t-1800t

即时报价

12

表面处理

0 件

订购数量

0.025 毫米

公差

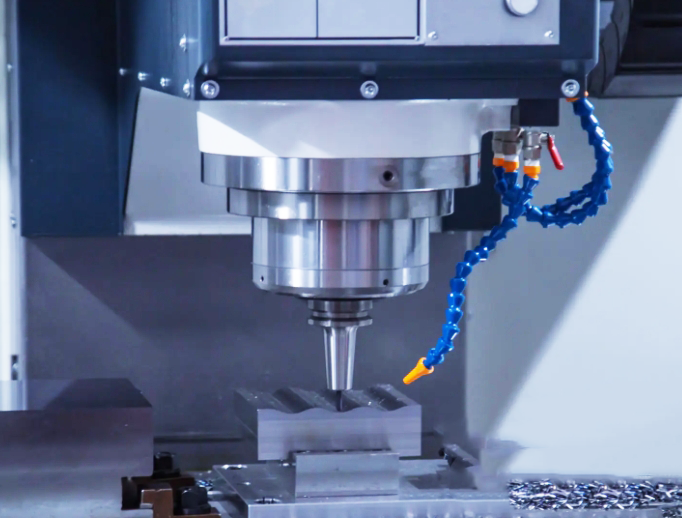

我们的定制激光切割服务

凭借出色的制造能力和 10 多年的行业经验,gch 可提供优质的定制激光切割服务,并具有出色的潜在效果。我们将技术娴熟的机械师与最先进的激光切割设备相结合,可切割从精致铝箔到厚钢板的任何材料。通过广泛的先进工艺和技术,享受金属激光切割服务。

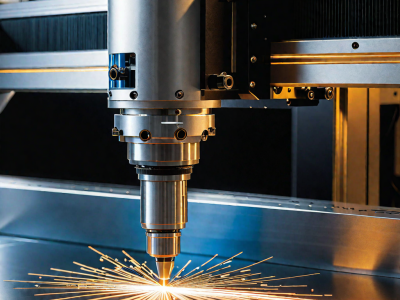

激光切割的优势

激光切割为许多行业提供了多种优势,包括精度、速度、可重复性和灵活性。GCH 的激光切割服务有助于满足行业对功能和美观的要求。

- 高精度切割:激光切割中的光束可确保材料的高精度熔化和蒸发,从而确保低至 0.003 毫米的精度。

- 最大限度地利用金属板:激光切割技术最大限度地提高了可用金属板的数量,几乎没有浪费的余地,确保只提供精确数量的材料。

- 切割功能强大:通过先进的激光切割操作,您可以定制激光切割部件,包括简单切割、标记、雕刻以及复杂、错综复杂的细节。

- 低能耗:金属板材激光切割机能有效切割材料而不消耗过多能源,通常只需 10 千瓦的能源。

- 几乎无损坏:激光切割过程中产生的热量对部件的影响极小,不会影响激光切割部件的公差。

从原型到生产的激光切割

激光切割的多功能性和精确性确保了出色的初始产品开发和连续生产。从复杂的定制部件到复杂的外壳,设计文件都能快速转化为最终产品。

坯料的制备

GCH 使用高精度激光切割机制作材料坯料,并为原型设计和生产准备平面图案。

快速原型制作

与各种材料的兼容性、生产速度和低单位成本使 GCH 的激光切割服务成为制作最终产品原型的理想选择。

GCH 激光切割能力

GCH 的定制包胶服务可确保生产出外观和性能更佳的塑料零件。我们的生产线采用包胶注塑工艺,可以将多种不同的材料融为一体,确保您获得质量上乘的产品。

| 标准 | 说明 |

| 最小部件尺寸 | 10 毫米(0.40 英寸) |

| 最小特征尺寸 | 2 倍材料厚度,最小 1 毫米(0.04 英寸) |

| 距离尺寸 | 我们的激光切割标准取决于 ISO 2768-c。 典型尺寸:长度、宽度、直径和位置为 +/- 0.2 毫米(0.008 英寸)。 |

| 最大材料厚度 | 碳钢 < 25 毫米(0.98 英寸),不锈钢 < 15 毫米(0.59 英寸),铝质 < 15 毫米(0.59 英寸),铜 < 12.7 毫米(0.5 英寸) |

| 角(缝隙大小) | 约 0.5 毫米(0.02 英寸) |

| 边缘状况 | 激光切割的边缘有哑光和垂直线条。 |

| 激光源 | CO2 和光纤激光器。功率可达 10 千瓦。 |

| 重复性 | +/- 0.05 毫米(0.002 英寸) |

| 定位精度 | +/- 0.10 毫米(0.004 英寸) |

| 准备时间 | 5-7 天 |

激光切割材料

GCH 的激光切割服务用途广泛,适用于从黑色金属到有色金属、塑料和其他非金属的各种材料。我们的激光切割设备结合了超现代技术和熟练的专业人员,可对不同强度、重量和热性能的材料进行激光切割。以下是一些可用于您的项目的激光切割材料。

塑料

还有许多塑料与激光切割工艺兼容。我们提供各种塑料,既能满足简单的商业应用,也能满足复杂的工业要求。GCH 的生产级塑料是医疗器械、齿轮、食品包装等的绝佳选择。常见的塑料包括

类型

PMMA

塑钢(聚甲醛、乙缩醛)

聚乙烯

聚丙烯

苯乙烯

琉璃

聚酯薄膜

丙烯酸

我们的亚克力激光切割服务具有广泛的价值,可帮助您满足各种应用的行业需求。通过改进技术,我们可以在亚克力材料上进行切割和雕刻,以达到最佳效果。GCH 可提供浇铸亚克力材料和挤压亚克力材料,以满足您的生产要求。

激光切割的加工选项

通过优质的表面处理方案,提高注塑件的表面质量。GCH 提供大量的表面处理方案,以提高产品的美观度。这些高效的二次加工还能提高原型和生产部件的机械质量。

| 名称 | 材料 | 颜色 | 纹理 | 厚度 | |

| 阳极氧化 | 铝质 | 透明、黑色、灰色、红色、蓝色、金色。 | 光滑的哑光表面。 | 薄层:5-20 微米 硬质阳极氧化膜:60-200 µm |

| 贝德爆破 | ABS、铝、黄铜、不锈钢、钢 | 不适用 | 亚光 | 0.3 毫米-6 毫米 |

| 粉末涂层 | 铝、不锈钢、钢 | 黑色,任何 RAL 代码或 Pantone 编号 | 亮光或半亮光 | 5052 铝 0.063″-0.500 英寸 6061 铝 0.063″-0.500 英寸 7075 铝 0.125"-0.250″ 低碳钢 0.048″-0.500″ 低碳钢 0.048″-0.500″ 低碳钢 4130 铬钼钢 0.050″-0.250″ 不锈钢 0.048″-0.250″ 英寸 0.048″-0.500″ 不锈钢 |

| 电镀 | 铝、钢、不锈钢 | 不适用 | 光滑亮泽的表面 | 30-500 µin |

| 抛光 | 铝、黄铜、不锈钢、钢 | 不适用 | 光泽 | 不适用 |

| 刷牙 | 铝、黄铜、不锈钢、钢 | 视情况而定 | 缎面 | 不适用 |

| 丝网印刷 | 铝、黄铜、不锈钢、钢 | 视情况而定 | 不适用 | < 1 µm |

| 钝化 | 不锈钢 | 无 | 不变 | 5μm - 25μm |

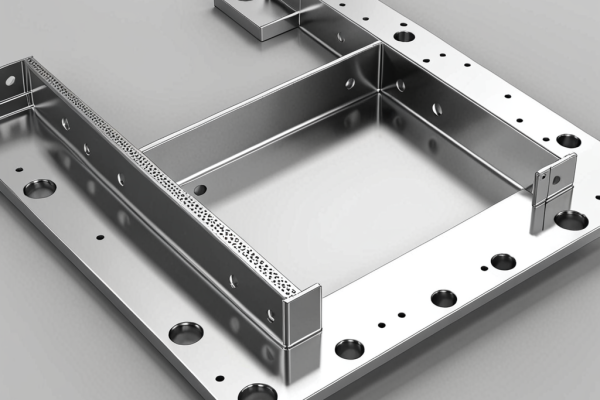

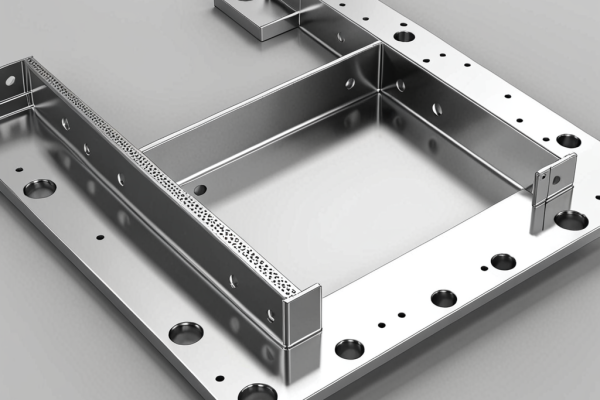

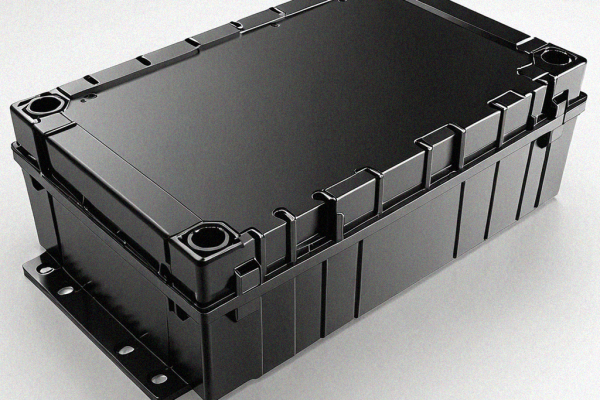

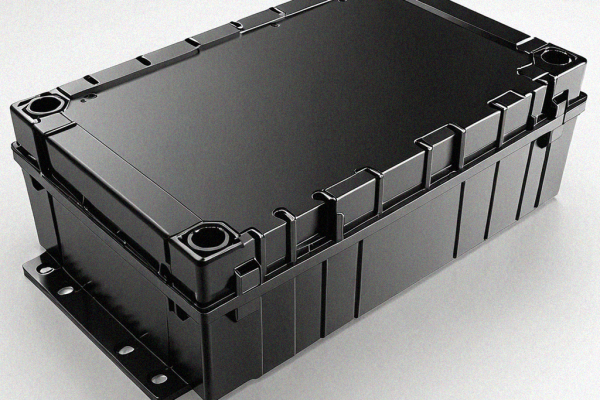

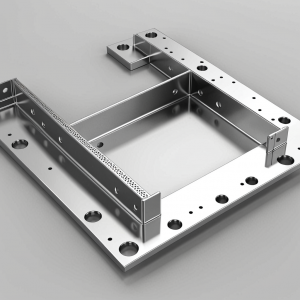

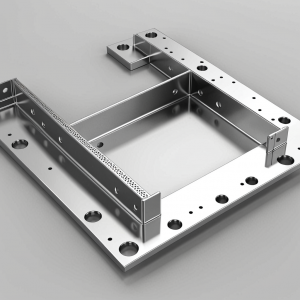

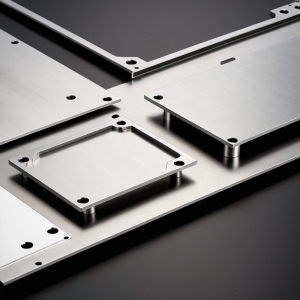

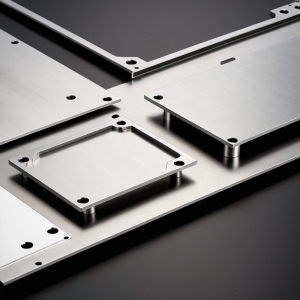

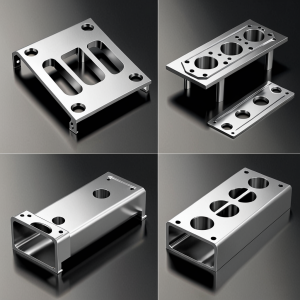

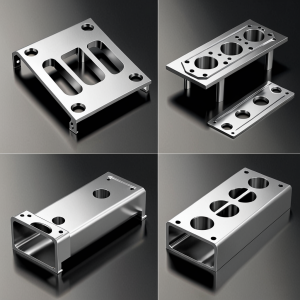

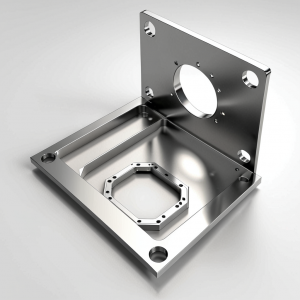

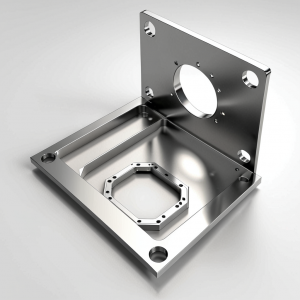

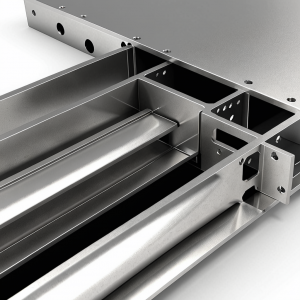

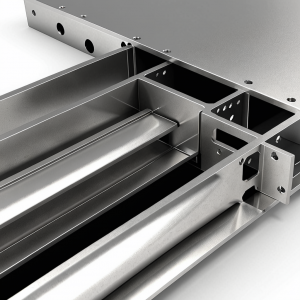

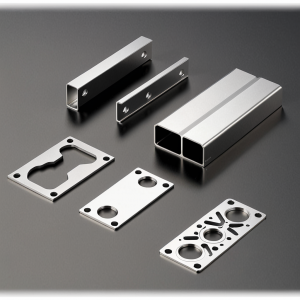

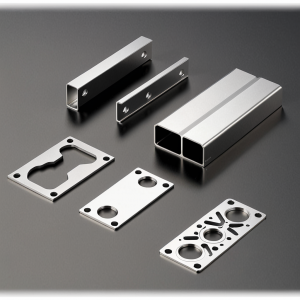

钣金激光切割部件图库

为什么选择 GCH

我们采取的方法旨在满足您的定制需求。我们旨在为工程专家和项目经理提供从设计到生产的长期原型包胶解决方案。GCH 将具有成本效益的模具与技术驱动的包覆成型服务相结合,有助于制造出高质量的零件。

无起订量

无最低订货量要求,有助于将塑料成型件从设计到生产的快速周转,并支持按需成型制造需求,降低注塑成型成本。

公差小、质量高

我们的注塑成型工艺包括重要的设计考虑因素,以提高成型性和美观性。GCH 可提供不同尺寸和复杂程度的注塑成型零件。我们的标准公差由 ISO 2768 标准规定,有助于我们满足严格的公差要求。

高效率

我们拥有经过认证的国内工厂和强大的供应链系统,能够加快产品开发周期,并为您尽快生产注塑件架起桥梁。

注塑成型专家

与我们在注塑行业拥有 10 多年经验的专家合作,高效地完成从原型设计到生产的周转。

定制激光切割如何工作?

注塑成型工艺包括将塑料原料送入注塑成型机,将其熔化,然后注入铝模或钢模。冷却后,一个生产级的热塑性塑料部件就成型了,然后顶出供进一步使用或组装。

用于各种应用的激光切割

请浏览 GCH 丰富的图库,其中展示了我们已完成的部分注塑件,您可以确信我们能够按照您的严格规格为您设计注塑项目。

常见问题

常见问题

我们的激光切割工艺与多种材料兼容,包括黑色和有色金属、塑料和其他非金属材料。我们还能切割不同重量、厚度和机械性能的材料。

我们的激光切割服务可切割的材料精度为 +/- 0.002 英寸,位置精度为 +/- 0.004 英寸。

针对不同的激光切割材料,GCH 有不同的厚度规格。不锈钢和铝的最大厚度小于 15 毫米。另一方面,我们可以切割厚度达 25 毫米的碳钢和小于 12.7 毫米的铜。

是的,我们的专家在激光雕刻和蚀刻方面拥有丰富的经验和知识。因此,我们能够提供满足您需求的优质服务。

是的,您可以使用 GCH 提供的各种弯曲技术对材料进行弯曲。平面型材中预留了弯曲空间。我们提供 V 形弯曲、滚动弯曲、旋转弯曲、擦拭弯曲等金属板弯曲技术。所使用的技术将取决于您的具体应用。

激光切割是一种高效的方法,可以以每分钟 600 英寸的切割速度切割钢材。这可确保快速完成多个切割项目,同时节省材料成本。有了我们精密的激光切割机,您可以确保更快的交货时间和合理的价格。

最新文章

Introduction To CNC Machining: Understanding The Basics Of CNC Machined Parts

Precision CNC machining parts for custom manufacturing solutions.

CNC Machining Industry 2025: Strategic Insights and Development Directions

I. Executive Summary: Navigating the 2025 CNC Industry Landscape and Strategic Imperatives The global Computer

数控加工在现代汽车制造中的作用

“CNC machining services for the automotive industry, offering high-performance, custom parts with precision engineering.”