Introduction: In the modern automotive manufacturing industry, custom automotive parts is increasingly becoming the driving force behind industry innovation and efficiency improvements. The development of CNC technology has not only revolutionized the precision of automotive part manufacturing but has also played a crucial role in areas such as supply chain management, customization services, and after-sales service. This article will delve into the multifaceted applications of CNC technology in the automotive industry and analyze how it is leading the transformation of the industry.

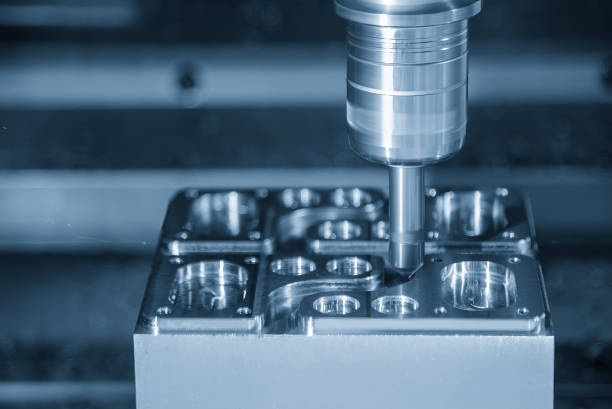

High-Precision Machining

CNC Technology Enhances Automotive Part Precision CNC technology, with its precise computer programming, achieves high-precision machining of automotive parts, ensuring interchangeability and assembly quality. This technology can produce complex shapes and structures that are difficult to achieve with traditional manual operations, significantly improving the precision and quality of automotive parts. In the automotive industry, CNC technology has become a key means to enhance production efficiency and reduce costs.

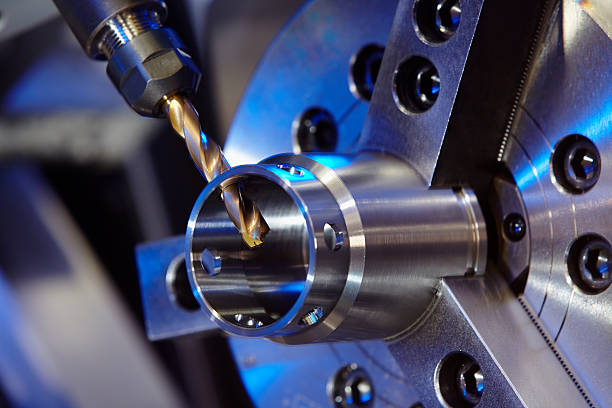

Material Innovation In Custom Automotive Parts

CNC Technology Drives Material Innovation in the Automotive Industry The high precision of CNC technology provides the automotive industry with more material options and innovation possibilities. Thanks to CNC technology’s ability to accurately machine parts from various new materials, such as titanium alloys and aluminum alloys, automotive designers can adopt lighter, stronger, and more complex materials and designs to improve vehicle performance and fuel efficiency. These innovative materials and designs are highly attractive in the automotive retail market, offering consumers better driving experiences.

Supply Chain Optimization

CNC Technology Optimizes Automotive Supply Chain Management The application of CNC technology makes the production and supply process of automotive parts more transparent and efficient. Through real-time monitoring and data analysis, manufacturers can better manage inventory and optimize the supply chain to ensure timely part delivery. This transparency and flexibility are vital for the automotive retail industry as they can reduce delivery times and inventory costs, enhancing customer satisfaction. CNC technology brings higher efficiency and sustainability to automotive supply chains.

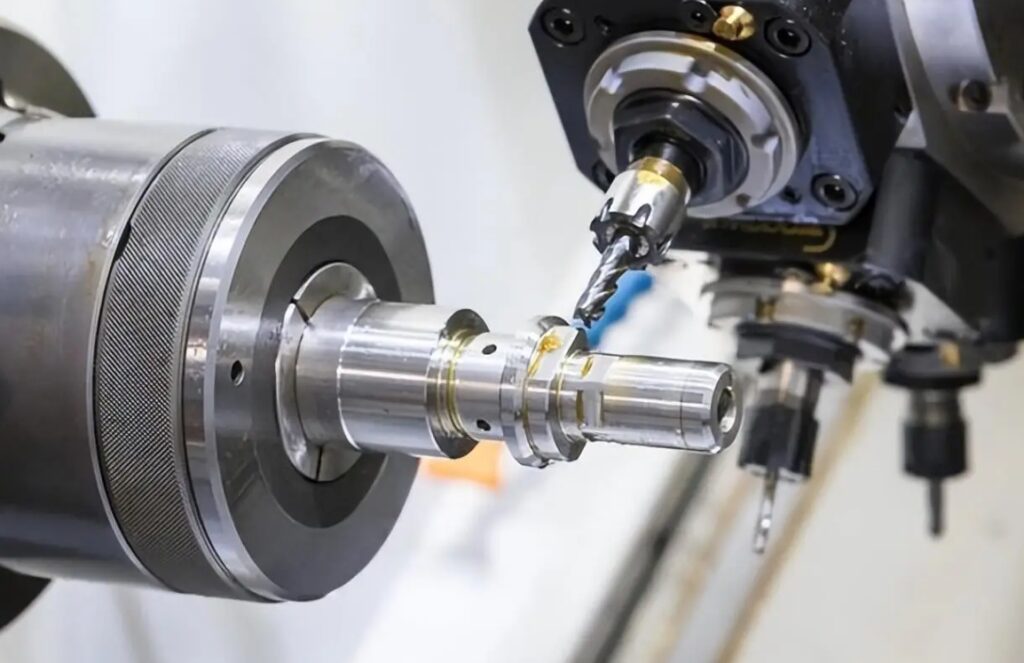

Custom Automotive Parts Services

Custom Automotive Parts Services in the Automotive Industry(custom automotive parts) The high flexibility of CNC technology enables manufacturers to provide customized and personalized automotive parts and services. This is a significant advantage for the automotive retail industry as it meets consumers’ demand for uniqueness and individualization, setting manufacturers apart in the competitive market. CNC technology brings higher customization capabilities to the automotive industry, offering consumers more choices and personalized automotive experiences.

After-Sales Service Improvement:

CNC Technology Enhances Automotive After-Sales Service Quality CNC technology is not only used in the automotive manufacturing process but also widely applied in automotive maintenance and after-sales service. High-precision CNC machining equipment can be used to repair and replace automotive parts, providing fast and high-quality after-sales service. This is an important selling point for automotive retailers as it can increase customer loyalty and word-of-mouth. CNC technology brings higher efficiency and precision to automotive after-sales service.

The development and application of CNC technology have had a profound impact on the automotive industry. And it makes it easy to custom automotive parts. From improving production efficiency and precision to driving industry innovation, optimizing supply chain management, and supporting customization and personalized services, CNC technology is reshaping the automotive industry. With the continuous advancement of CNC technology, we can expect a more efficient, innovative, and personalized production and sales market in the automotive industry. The automotive industry is entering a new era, and CNC technology is the key force driving this transformation.

As a professional automotive parts manufacturer, holds an IATF:16949 certificate and has excellent automotive part production capabilities. Our factory is equipped with advanced 5-axis machining equipment, allowing us to provide highly specialized automotive parts. Through real-time monitoring and data analysis, we can better manage inventory, optimize the supply chain, and ensure timely part delivery. Additionally, we can provide customized and personalized automotive parts and services to meet consumers’ demand for uniqueness and individualization. With the continuous advancement of CNC technology, we look forward to the automotive industry achieving more efficient, innovative, and personalized production and sales.