3D Printing: The Wonder of Additive Manufacturing

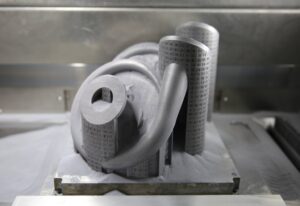

Understanding the Technology

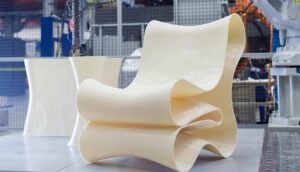

3D printing, also known as additive manufacturing, has revolutionized the way we create objects. By building objects layer by layer from digital models, this technology opens up new possibilities in manufacturing that were previously unimaginable.

Key Advantages

- Design Freedom: Imagine being able to create complex internal structures or intricate lattice designs that would be impossible with traditional manufacturing methods. 3D printing makes these dreams a reality, pushing the boundaries of what’s possible in product design.

- Rapid Prototyping: Need to validate your design quickly? With 3D printing, you can have a physical prototype in your hands within hours, not days or weeks. This rapid iteration capability is invaluable for product development and testing.

- Customization: Whether you’re creating custom medical devices or personalized jewelry, 3D printing excels at producing one-off or small batch items without the need for expensive tooling.

Real-world Limitations

- Precision and Surface Finish: While improving constantly, 3D printing still can’t match the precision of CNC machining for certain applications. The layer-by-layer building process can sometimes result in visible layer lines.

- Production Speed: For large production runs, 3D printing might not be your best choice. The printing process can be relatively slow, especially for complex or large objects.

- Material Constraints: Though the range of printable materials continues to expand, it’s still more limited compared to traditional manufacturing methods.

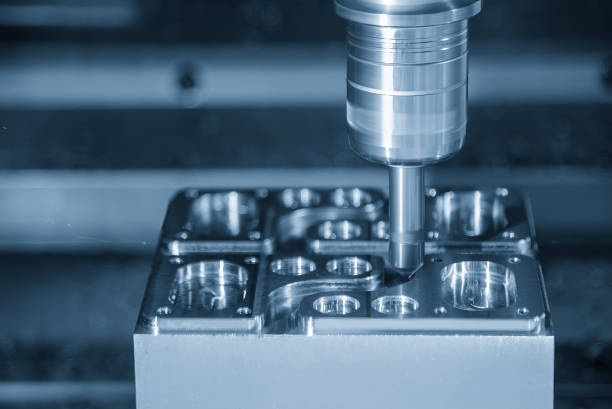

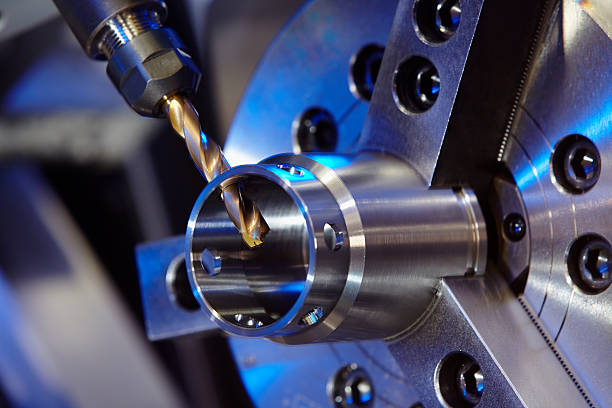

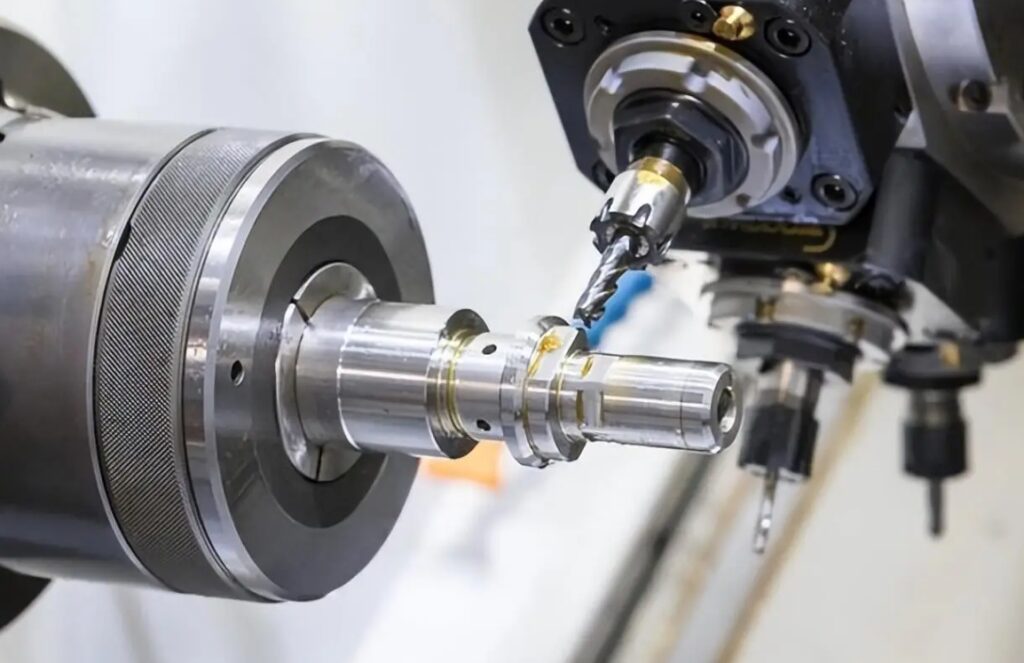

CNC Machining: The Gold Standard of Precision Manufacturing

Core Technology

CNC işleme uses computer-controlled tools to remove material from a solid block, creating precise parts with excellent repeatability. Think of it as digital sculpting on an industrial scale.

Notable Strengths

- Exceptional Accuracy: When precision is paramount, CNC machining shines. It can achieve tolerances down to micrometers, making it perfect for aerospace components or medical devices.

- Production Efficiency: Once programmed, CNC machines can produce identical parts continuously with remarkable consistency. This makes them ideal for medium to large production runs.

- Material Versatility: From aluminum and steel to exotic alloys and plastics, CNC machines can work with almost any machinable material you can think of.

Limitations

- Initial Investment: Professional CNC equipment requires significant upfront investment. This can be a barrier for smaller operations or startups.

- Design Restrictions: Some complex internal geometries might be impossible to machine due to tool access limitations. Think of it like trying to carve the inside of a hollow ball – some shapes are just too difficult to reach.

Making the Right Choice

Consider Your Product Requirements

- Complex geometries? 3D printing might be your answer.

- Need high precision and strength? Look toward CNC machining.

Production Volume Analysis

- For prototypes or small batches, 3D printing often makes more sense.

- Large production runs? CNC machining typically becomes more cost-effective.

Cost Considerations

Think about:

- Equipment investment

- Material costs

- Labor requirements

- Production speed

- Quality requirements

Future Trends

Technology Convergence

We’re seeing exciting developments in hybrid manufacturing systems that combine both technologies. Imagine the precision of CNC machining with the design freedom of 3D printing – the best of both worlds.

Smart Manufacturing

The integration of AI and IoT is making both technologies smarter and more efficient. Real-time monitoring and adjustment capabilities are becoming the norm, not the exception.

Material Innovations

New materials are constantly being developed, especially for 3D printing. From high-performance polymers to biocompatible materials, the possibilities keep expanding.

Practical Tips and Recommendations

Start with Requirements

Before choosing a manufacturing method, clearly define your:

- Product specifications

- Production volume

- Budget constraints

- Timeline requirements

Consider Hybrid Approaches

Sometimes, using both technologies makes perfect sense. You might 3D print prototypes for testing, then switch to CNC machining for final production.

Stay Informed

Manufacturing technology is evolving rapidly. Keep up with new developments to make informed decisions for your projects.

Sonuç

Choosing between 3D printing and CNC machining isn’t about finding the “better” technology – it’s about finding the right solution for your specific needs. By understanding the strengths and limitations of each method, you can make an informed decision that balances cost, quality, and efficiency.

Remember, the best manufacturing solution often depends on your unique circumstances. Whether you choose 3D printing, CNC machining, or a combination of both, focus on what works best for your specific project requirements.

As these technologies continue to evolve, we’ll likely see even more exciting capabilities and applications emerge. Stay curious, keep learning, and don’t be afraid to experiment with different approaches to find your perfect manufacturing solution.