Have you ever wondered how intricate metal parts or complex plastic components are made with such precision? The answer often lies in CNC işleme hizmetleri. Whether you’re new to the world of manufacturing or looking to learn more about CNC machining services for your next project, this guide will walk you through everything you need to know.

Why Choose CNC Machining Services?

When considering CNC machining services, there are several compelling reasons why businesses and engineers choose this manufacturing method:

High Precision and Accuracy

CNC machining services are known for their ability to produce parts with extremely high precision and accuracy. The CNC machines follow programmed instructions with meticulous attention to detail, achieving tolerances as tight as a few microns. This level of precision is particularly important for industries where even the smallest deviation can affect performance, such as in aerospace and medical device manufacturing.

Versatility in Material and Application

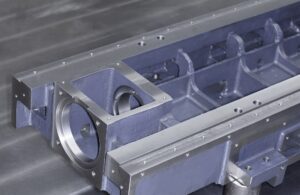

CNC machining services are incredibly versatile, capable of working with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics, wood, and even composites. This versatility means that CNC machining can be used for a vast array of applications, from creating small, intricate components to large structural parts.

Consistency and Repeatability

One of the standout features of CNC machining services is their ability to consistently produce parts that meet the same specifications time and time again. Whether you’re manufacturing a single prototype or thousands of identical parts, CNC machines ensure that each piece is virtually indistinguishable from the next. This repeatability is invaluable in mass production, where consistency is key to maintaining quality and reducing waste.

Efficient Production and Quick Turnaround

Thanks to the automation and precision of CNC machines, CNC işleme hizmetleri can significantly reduce production times. Once the machine is programmed, it can operate continuously with minimal human intervention, which speeds up the manufacturing process and reduces labor costs. This efficiency is ideal for projects with tight deadlines or for businesses looking to scale up production quickly.

Cost-Effective for Prototyping and Production

While the initial setup for CNC machining services might seem costly due to the need for programming and tooling, the overall cost is often lower in the long run. This is because CNC machines minimize material waste, reduce labor costs, and can quickly switch between different tasks without the need for extensive reconfiguration. This cost-effectiveness makes CNC machining services a popular choice for both prototyping and full-scale production.

CNC İşleme Süreci

To fully understand CNC machining services, it’s important to grasp the basics of the CNC machining process. Here’s a step-by-step breakdown:

Designing the Part

The first step in any CNC machining project is designing the part you want to create. Engineers use CAD (Computer-Aided Design) software to produce a detailed 3D model of the part, specifying all the necessary dimensions, features, and tolerances. This model serves as a blueprint for the CNC machine, guiding it through the machining process.

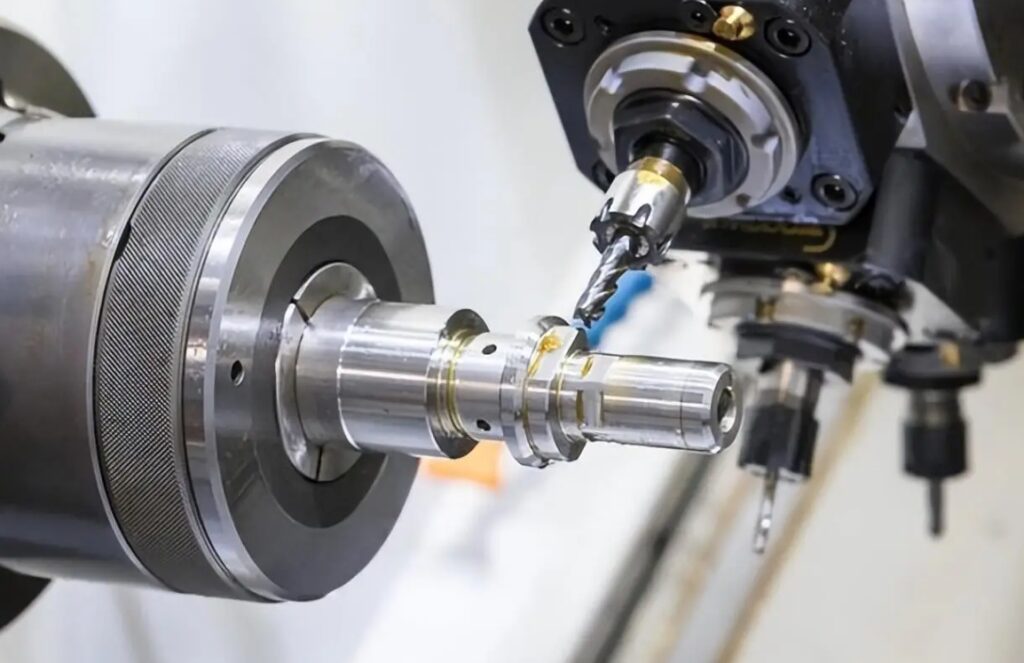

Setting Up the CNC Machine

Before machining can begin, the CNC machine must be set up with the appropriate tools and materials. This involves selecting the right cutting tools (such as drills, mills, and lathes), loading the material onto the machine’s worktable, and calibrating the machine to ensure precision. Proper setup is crucial to achieving accurate and efficient machining.

Converting the Design to G-Code

Once the design is complete, it needs to be translated into a language that the CNC machine can understand. This is done using CAM (Computer-Aided Manufacturing) software, which converts the CAD model into G-code. G-code is a programming language that tells the CNC machine how to move, what speed to use, and which tools to engage to produce the desired part.

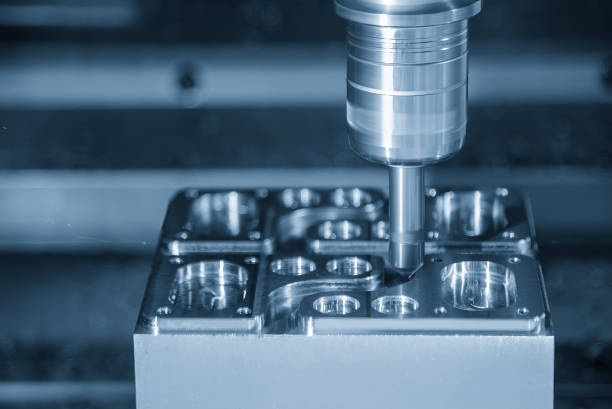

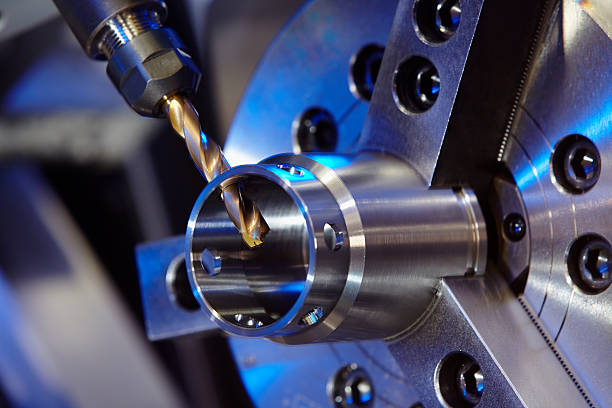

Machining the Part

With everything set up, the CNC machine can start the machining process. Guided by the G-code, the machine performs a series of precise movements to cut, shape, and finish the part from the raw material. This process can involve multiple stages, including rough cutting, finishing, and drilling, depending on the complexity of the part. The operator monitors the machine during this process to ensure everything is running smoothly and to make any necessary adjustments.

Post-Machining Processes

After the CNC machine has completed the initial machining, the part may require additional post-machining processes to achieve the desired finish and functionality. This could include deburring to remove sharp edges, polishing for a smooth surface, anodizing for corrosion resistance, or heat treatment to enhance the material’s properties. These post-machining steps are essential for ensuring the part meets all the necessary specifications and quality standards.

Common Applications of CNC Machining Services

CNC machining services are used across a wide range of industries due to their versatility and precision. Here are some of the most common applications:

Havacılık ve Uzay

In the aerospace industry, CNC machining services are used to produce complex components that require high precision and reliability, such as turbine blades, engine parts, and structural components. The ability to machine parts to exact specifications is critical in aerospace, where safety and performance are paramount.

Otomotiv

CNC machining services are widely used in the automotive industry to manufacture various parts, including engine components, transmission parts, and suspension systems. The consistency and repeatability of CNC machining make it ideal for mass-producing automotive parts that must meet strict quality standards.

Tıbbi Cihazlar

The medical device industry relies heavily on CNC machining services to produce precision parts for surgical instruments, implants, and diagnostic equipment. The high level of accuracy and the ability to work with biocompatible materials make CNC machining an essential process for manufacturing medical devices.

Elektronik

In the electronics industry, CNC machining services are used to create housings, connectors, and other components that require tight tolerances and precise dimensions. CNC machining can also be used to produce custom enclosures and fixtures for electronic devices.

Tüketici Ürünleri

CNC machining services are used to create a wide range of consumer products, from custom kitchenware to sporting equipment. The versatility of CNC machining allows manufacturers to produce high-quality, durable products with intricate designs.

Choosing the Right CNC Machining Service Provider

With so many CNC machining service providers available, it can be challenging to choose the right one for your project. Here are some factors to consider when selecting a CNC machining service provider:

Experience and Expertise

Look for a provider with extensive experience in CNC machining services, particularly in your industry. An experienced provider will have the knowledge and skills to handle complex projects and deliver high-quality results.

Range of Services

Choose a provider that offers a wide range of CNC machining services, including milling, turning, drilling, and grinding. This ensures that they have the capabilities to meet your specific needs and can handle any challenges that may arise during the machining process.

Kalite Kontrol

Quality control is critical in CNC machining services. Look for a provider that has a robust quality management system in place, with certifications such as ISO 9001 or AS9100. This ensures that they adhere to strict quality standards and can consistently deliver high-quality parts.

Technology and Equipment

Choose a provider that uses state-of-the-art CNC machines and software. Advanced technology and equipment can significantly improve the precision, efficiency, and quality of the machining process.

Customer Service

Finally, consider the level of customer service provided by the CNC machining service provider. Look for a company that is responsive, communicative, and willing to work closely with you to ensure your project’s success.

The Future of CNC Machining Services

As technology continues to evolve, so do CNC machining services. The future of CNC machining will likely see increased automation, with more advanced machines capable of performing multiple tasks simultaneously and reducing the need for human intervention. Additionally, the integration of artificial intelligence and machine learning could further optimize the machining process, improving efficiency and reducing costs.

Another exciting development in CNC machining services is the use of additive manufacturing techniques, such as 3D printing, in conjunction with traditional CNC machining. This hybrid approach allows manufacturers to create complex parts with a combination of additive and subtractive processes, offering greater design flexibility and reducing material waste.

Sonuç

CNC machining services play a crucial role in modern manufacturing, offering precision, efficiency, and versatility for a wide range of applications. Whether you’re looking to produce a single prototype or mass-produce thousands of parts, CNC machining services can meet your needs with high-quality results.

By understanding the benefits and processes of CNC machining services, you can make informed decisions for your next project and choose the right service provider to ensure success. If you’re ready to explore the possibilities of CNC machining services or have any questions, don’t hesitate to reach out! Our team of experts is here to help you navigate the world of CNC machining and bring your ideas to life.