How to Reduce CNC Machining Costs: 24 Tips and Strategies?

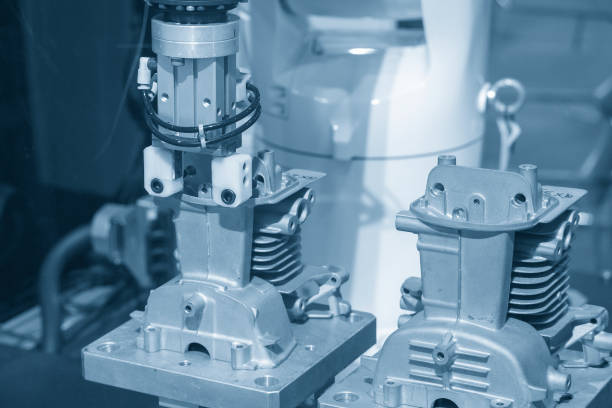

In today’s manufacturing landscape, minimizing CNC machining costs is essential for maintaining a competitive edge. While CNC machining provides precision and efficiency, it can also be costly. This article explores practical strategies to lower these costs, offering actionable insights to optimize your manufacturing budget without compromising quality.

Factors Influencing CNC Machining Costs

Understanding the various factors that contribute to CNC machining costs is crucial for identifying cost-reduction opportunities. Here are 28 elements that can influence the bottom line of your CNC machining projects:

- Malzeme Seçimi: Choosing the right material is vital, as costs can vary significantly. Metals, plastics, and specialty alloys each have unique price points and machinability factors.

- Machine-Related Costs: Initial setup, machine capabilities (number of axes), and specific operations required can impact costs. High-precision machines with extensive capabilities might be more expensive but can deliver superior results.

- Machine Operation and Setup Time: Time directly affects project costs. Efficient setup and operation can lead to significant savings.

- Part Complexity: Complex parts require more sophisticated programming, longer machining times, and more material, increasing costs.

- Size and Geometry of the Part: Larger and more geometrically complex parts need more material and machining time.

- Yüzey İşlem Gereksinimleri: Higher quality finishes may necessitate additional machining steps or special processes, adding to costs.

- Tolerance Requirements: Tighter tolerances require more precise machining, increasing costs due to added time and expertise.

- Volume of Production: Larger volumes can reduce cost per unit through economies of scale.

- Type of CNC Machine Used: Different machines offer varying precision and capabilities, affecting costs.

- Tooling and Consumables: Specific tools and their wear rates can add to project costs.

- İşçilik Maliyetleri: Skilled technicians are essential but come at a cost. Efficient management and training can help control expenses.

- Secondary Processes and Finishes: Post-processing steps like anodizing or heat treatment can add to the final cost.

- Energy Consumption: The energy required to operate CNC machines contributes to operational costs.

- Software and Design: High-quality CAD/CAM software and design work investment can affect overall costs.

- Waste Material: Efficient material utilization and minimizing waste can help reduce costs.

- Coolant and Lubrication Systems: Necessary for machine operation, these systems have associated costs.

- Machine Amortization: The depreciation of CNC machinery over time is factored into project costs.

- Technical Support and Maintenance: Regular maintenance and access to technical support ensure machine longevity but at a cost.

- Energy Efficiency of Machinery: Machines with higher energy efficiency can reduce long-term operating costs.

- Customization of CNC Programs: Custom programming for specific projects can increase costs but may be necessary for complex parts.

- Adherence to Regulatory and Safety Standards: Compliance with industry standards ensures safety and quality but can add to costs.

- Supply Chain Stability: A stable supply of materials is crucial for predictable pricing and availability.

- Inflation and Economic Conditions: Fluctuating economic conditions can affect material and labor costs.

- Environmental and Sustainability Practices: Implementing green practices can have upfront costs but may lead to savings and compliance with regulations.

- Training and Education: Ongoing education and training for staff ensure high-quality output but require investment.

- Capacity Utilization: Maximizing the use of machinery can improve cost efficiency.

- Global Market Fluctuations: International supply and demand can impact material costs.

- Client-Specific Requirements: Custom requirements can lead to additional engineering and manufacturing costs.

Best Practices for Reducing CNC Machining Costs

Optimizing cost efficiency while maintaining high-quality output is crucial for businesses in CNC machining. Here are core strategies to help reduce CNC machining costs:

- Simplify Part Designs: Reducing part complexity minimizes machining steps, leading to more efficient production cycles.

- Use Standardized Components: Integrating standardized components can eliminate the need for custom tooling and reduce overall complexity.

- Select Cost-effective Materials: Choose materials that meet functional requirements and are cost-effective.

- Utilize the Right CNC Machine: Match part requirements to machine capabilities to prevent overspending.

- Implement Efficient Tooling Strategies: Optimize tool paths and select multipurpose tools to reduce machine time.

- Apply Cost-Effective Tolerances: Adjust tolerances to the most cost-effective levels that do not compromise functionality.

- Minimize Manual Finishing Processes: Automated finishing can reduce the need for labor-intensive manual processes.

- Batch Production: Leverage economies of scale by producing parts in batches.

- Engage in Early Supplier Involvement (ESI): Collaborate with suppliers early to identify cost-saving opportunities in the design phase.

- Consider Advanced Manufacturing Technologies: Use technologies like 3D printing to complement CNC machining and reduce material waste.

- Continuous Improvement and Lean Manufacturing: Adopt a philosophy of continuous improvement and lean manufacturing practices.

- Quality Control and Process Optimization: Implement stringent quality control measures to reduce errors and rework.

- Invest in Training and Skill Development: Skilled operators can maximize machine efficiency.

- Analyze the Entire Production Workflow: Identify inefficiencies and bottlenecks in the production workflow.

- Outsource Strategically: Outsource specific operations to specialized providers if more cost-effective.

- Optimize Machining Paths and Strategies: Use advanced software to optimize machining paths.

- Adopt Predictive Maintenance: Regular maintenance based on predictive analytics prevents costly downtime.

- Utilize Data Analytics: Analyze production data to identify improvement areas.

- Explore Alternative Machining Methods: Evaluate alternative methods like waterjet or laser cutting.

- Implement Sustainability Practices: Sustainable practices can lead to cost savings through energy efficiency and waste reduction.

- Design for Machinability: Design parts with machinability in mind to reduce machining time and costs.

- Review and Optimize the Supply Chain: Streamline supply chains to reduce material costs and lead times.

- Incorporate Feedback Loops: Establish feedback loops between design, engineering, and manufacturing teams.

- Risk Management in CNC Operations: Identify and mitigate risks to prevent costly mistakes and downtime.

Mistakes to Avoid When Reducing CNC Machining Costs

Reducing CNC machining costs requires strategic planning. Avoid these common mistakes to achieve effective cost reduction:

- Over-Specifying Tolerances: Applying tighter tolerances than necessary can significantly increase costs.

- Ignoring Material Properties: Choosing materials without considering machinability and cost implications can lead to increased expenses.

- Complex Designs Without Consideration for Machining: Overly complex designs can complicate the machining process and increase costs.

- Neglecting Design for Manufacturability (DFM): Failing to incorporate DFM principles can result in expensive production.

- Underestimating the Impact of Setup Times: Setup times can significantly contribute to overall costs.

- Skipping Prototyping: Skipping prototyping can lead to costly design errors during full-scale production.

- Failing to Leverage Standard Components: Custom components are often more costly than standard parts.

- Overlooking the Benefits of Bulk Production: Bulk production can reduce the cost per unit.

- Inadequate Supplier Communication: Miscommunication can lead to delays, increased costs, and suboptimal material choices.

- Ignoring Secondary Operations and Finishes: Consider secondary processes in cost analysis to streamline or eliminate unnecessary steps.

- Choosing the Wrong Machining Process: Selecting an unsuitable machining process can increase costs.

- Underutilizing Technology and Automation: Not leveraging modern CNC technologies can result in higher costs.

- Disregarding Energy Consumption: Efficient use of machinery and energy-efficient technologies can contribute to cost reductions.

- Not Planning for Waste Management: Effective planning and material utilization strategies can minimize waste and reduce costs.

Sonuç

Balancing CNC machining cost efficiency with high standards of quality and precision is a challenge. By adopting best practices and avoiding common pitfalls, manufacturers can optimize their operations and secure a competitive advantage. Effective cost management in CNC machining involves strategic decisions that enhance value and efficiency across the production lifecycle. Stay updated on the latest techniques, materials, and technologies while fostering a culture of continuous improvement to thrive in the dynamic manufacturing landscape.

Latest Articles

- What is ISO9001-2015: Importance, Structure, Benefits & Implementation

- The Comprehensive Guide to CMM Inspection

- What Is Bridge Production and Manufacturing

- Revolutionizing Energy: The Role of CNC Machining in the Energy Industry

- Exploring the Precision and Versatility of Glass CNC Machining: A Comprehensive Guide

Share this blog:

By implementing these strategies, you can effectively manage and reduce CNC machining costs while maintaining the high-quality output that defines precision engineering.