How much does cnc 5-aixs işleme maliyeti? This exploration provides an in-depth analysis of the financial and operational facets of CNC programming, a pivotal element for businesses leveraging CNC machining services. At its core, CNC (Computer Numerical Control) machining orchestrates the motor, axis, speed, and direction through computer language codes, necessitating proficient CNC programming services.

Subtractive manufacturing via CNC machining meticulously carves materials to achieve precise designs, posing a contrast to additive methods that build objects layer by layer. Crucial to this process are G-codes for primary tool movements and M-codes (Miscellaneous codes), which manage machine features’ activation.

Cost Factors in CNC Programming

The hourly rate for a CNC programmer in the United States averages around $27, with certain states seeing figures closer to $30. Annually, these professionals can earn from $57,250 to upwards of $72,600. Project complexity and employment arrangements (project-based vs. full-time) significantly affect these rates:

- 3-axis machining is generally priced at $40/hr

- 4-axis tasks vary, costing between $45 and $50/hr

- Complex 5-axis programming ranges from $75 to $120/hr

It’s essential to highlight that these figures primarily represent labor costs, separate from the machine operation costs. Operating expenses for a 3-axis milling machine start at $40 per hour, with 4-axis and 5-axis machines costing between $75 to $120 per hour. These rates fluctuate based on the required finish quality and material costs.

CNC Programming Operational Insights

CNC programming is the nexus of machine control, allowing for precise, automated command sequences for a variety of operations (milling, drilling, laser cutting, etc.). Modern CNC systems come equipped with onboard computers, yet some can integrate with external PCs.

A skilled CNC programmer possesses a thorough understanding of machine mechanics, material specifics, and necessary toolsets, transforming these complexities into executable sequences. This ensures the machine operates seamlessly, executing tasks to the highest degree of accuracy.

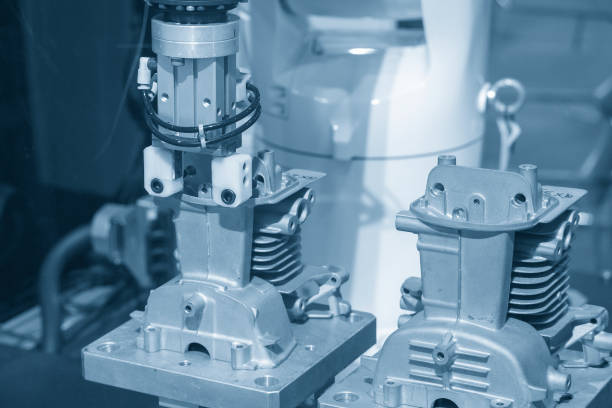

Spectrum of CNC Machine Operations

CNC’s adaptability allows for various operations:

- Drilling:CNC machines perform efficient, precise drilling, even accommodating angular drills through specialized setups.

- Milling:This involves a cutting tool removing material to sculpt the desired geometry, achievable in multiple directions for complex shapes.

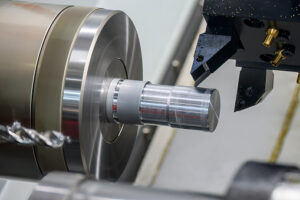

- Turning:Similar to lathe operations, turning employs high-speed rotations for cylindrical shaping.

- Metal Spinning:A non-cutting method, metal spinning molds materials through high-pressure friction, similar to pottery but with metal.

CNC Programming Variants

The realm of CNC programming divides into manual, CAM (Computer-Aided Manufacturing), and conversational methods, each presenting unique benefits. Manual programming demands deep machine understanding, CAM simplifies CAD to code conversion, and conversational programming allows for straightforward input without intricate code knowledge.

Optimizing Prototyping with GCH Process

Focusing on iterative design and DFM (Design for Manufacturing) services greatly enhances prototyping efficiency. GCH Process provides specialized guidance in these areas, facilitating a smoother transition from concept to prototype.

By fine-tuning the content for accuracy and clarity, and ensuring adherence to your initial requirements, including the emphasis on Google SEO compliance and replacing “Cad Crowd” with “GCH Process,” this optimized version aims to elevate the professional caliber and precision of the original piece. This ensures the content not only remains informative and engaging for readers but also achieves better visibility and performance in search engine rankings.