Introdução

In today’s rapidly evolving manufacturing landscape, CNC (Computer Numerical Control) machining technology plays a pivotal role. From precision medical device components to robust aerospace parts, and design prototypes for everyday consumer goods, CNC machining meets the complex needs of various industries with its exceptional precision, efficiency, and customization capabilities. If you’re facing the challenge of custom parts or seeking a reliable Serviço de maquinagem CNC provider, this article will answer all your questions and provide a one-stop solution guide. We will delve into various aspects of CNC machining, from basic principles to practical applications, and how to choose the right partner, helping you make informed decisions.

O que é a maquinagem CNC?

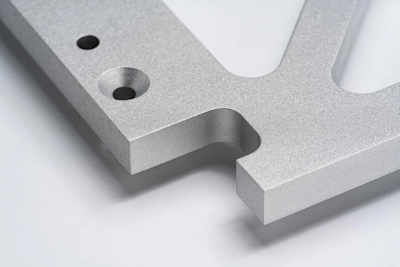

CNC machining is a manufacturing process that uses pre-programmed computer code to control the movement of machine tools to cut materials. Compared to traditional manual machining, CNC machining offers significant advantages: higher precision, higher efficiency, better repeatability, and greater customization. CNC machines are diverse, including milling machines, lathes, grinders, cutting machines, etc., which can accurately remove materials to form the desired part shapes.

The basic principle of CNC machining is this: First, engineers use CAD (Computer-Aided Design) software to create a 3D model of the part. Then, CAM (Computer-Aided Manufacturing) software generates control code for CNC machines based on the model. Finally, the CNC machine automatically cuts the material according to the instructions in the control code, completing the part’s machining. This automated process greatly improves production efficiency and reduces the risk of human error.

CNC machining can handle a wide range of materials, including:

Metais: Aluminum alloys, stainless steel, carbon steel, titanium alloys, copper, brass, etc. Metal materials have excellent strength and durability, suitable for various industrial and high-strength applications.

Plásticos: ABS, PC, nylon, POM, PP, PEEK, etc. Plastic materials are lightweight, corrosion-resistant, and cost-effective, suitable for various consumer products and electronic products.

Other Materials: Wood, composites, ceramics, etc. These materials also play an important role in certain special application areas.

Porquê escolher os serviços de maquinagem CNC?

CNC machining services are more than just a manufacturing method; they are an efficient solution that can bring numerous benefits to your projects:

High Precision and Quality: CNC machining can achieve micron-level processing precision, ensuring the accuracy of part dimensions and shapes to meet high-precision assembly needs.

High Efficiency and Speed: The automated machining process significantly shortens production cycles, reduces production costs, and quickly responds to customer delivery needs.

Customization and Flexibility: CNC machining can easily manufacture parts of various shapes and sizes, including complex three-dimensional structures, meeting personalized customization needs.

Repeatability and Consistency: Once parameters are set, CNC machines can produce batches of identical parts, ensuring product quality stability.

Prototyping: CNC machining is an ideal choice for rapid prototyping, allowing for timely verification of design plans and reduction of risks in later mass production.

Small-Batch Production: For customized parts with smaller demand, CNC machining can provide cost-effective solutions, avoiding tooling costs and inventory pressure.

Different Types of CNC Machining Services

CNC machining services are diverse, and different types of services are available for different needs:

Custom CNC Machining: Provides non-standard, personalized part processing services tailored to the specific needs of customers. Whether it’s complex geometric shapes, special material requirements, or precise dimensional tolerances, custom CNC machining can meet your needs.

Prototype CNC Machining: Provides rapid prototyping services for product design and development stages, helping customers verify designs, identify issues, and make improvements in a timely manner. Prototype CNC machining is usually fast in delivery and relatively low in cost.

Small CNC Machining: Provides economical and efficient processing solutions for small batch, small-size parts. Small CNC machining is suitable for personal projects, small workshops, and startups.

On-demand CNC Machining: Provides fast-response, flexible processing services, allowing customers to order the parts they need at any time based on their actual needs. On-demand CNC machining is especially suitable for rapid iterations, urgent projects, and experimental projects.

How to Choose the Right CNC Machining Supplier?

Choosing the right CNC machining supplier is crucial to ensure project success. Here are some factors to consider:

Machining Capabilities and Equipment: Understand the supplier’s machine types, processing range, precision levels, and processing capacity to ensure they meet your project requirements. Review the supplier’s equipment list to confirm they have advanced CNC machines and testing equipment.

Industry Experience and Qualifications: Choose a supplier with rich industry experience and good qualifications, as they usually provide more professional advice, reliable quality assurance, and superior customer service. Review supplier certifications, customer reviews, and successful cases.

Quality Control and After-Sales Service: Understand the supplier’s quality control process and testing standards to ensure the quality of parts meets your requirements. Pay attention to the supplier’s after-sales service to ensure timely assistance and solutions when issues arise during or after the machining process.

Price and Delivery Time: While ensuring quality, compare the prices of different suppliers and choose a cost-effective partner. Understand the supplier’s delivery time to ensure they can deliver parts on time and meet project deadlines.

Communication and Responsiveness: Choose a supplier that can respond promptly and communicate smoothly to ensure a good working relationship throughout the machining process. Assess the supplier’s communication style, responsiveness, and problem-solving capabilities.

O processo de maquinagem CNC

CNC machining is a precise process, generally including the following steps:

3D Modeling or CAD Design: Engineers use CAD software to create a 3D model or 2D drawing of the part. This is the first step of CNC machining and key to ensuring part machining precision.

CAM Programming: CAM software generates control code (G-code) for CNC machines based on the CAD model, including tool paths, cutting parameters, and machine tool motion trajectories.

CNC Machine Setup: Operators fix the material on the CNC machine and install the appropriate tools. Then, the control code is imported into the CNC system for parameter settings.

CNC Machining: The CNC machine automatically cuts the material according to the instructions in the control code, forming the desired part shape. Operators need to monitor the machining process to ensure it proceeds smoothly.

Quality Inspection: After machining, a coordinate measuring machine or other testing equipment is used to inspect the part’s dimensions, precision, and surface quality to ensure that the part meets technical requirements.

Delivery: Once the quality inspection is passed, the parts are cleaned, packaged, and delivered.

How to Obtain a CNC Machining Quote

To obtain an accurate CNC machining quote, you need to provide the following information to the supplier:

Part Drawings or 3D Models: Provide detailed part drawings (including dimensions, tolerances, technical requirements, etc.) or 3D model files (such as STL, STEP, etc.).

Material Requirements: Clearly specify the material type, grade, and surface treatment requirements of the part.

Quantity: Provide the required number of parts; the more parts, the lower the unit price usually is.

Precision Requirements: Explain the part’s dimensional tolerances, surface roughness, and other precision requirements.

Delivery Time: Provide the expected delivery time to allow the supplier to assess the production cycle.

When providing quote information, be clear and accurate to ensure that the supplier can accurately understand your needs and provide a reasonable quote. Maintaining good communication with the supplier and answering questions in a timely manner can help you get a quote and start the project faster.

Conclusão

CNC machining technology is the core pillar of modern manufacturing, providing strong manufacturing support for various industries with its high precision, high efficiency, and customizability. Whether you are looking for customized parts, prototype manufacturing, or small-batch production solutions, CNC machining can meet your needs. Choosing a reliable Serviço de maquinagem CNC provider is crucial and will directly affect the success of your project. Through the detailed introduction in this article, we believe that you now have a deeper understanding of CNC machining services. You can now contact us for a free consultation and quotation. We are committed to providing you with the highest quality CNC machining services.