In the realm of advanced manufacturing, precision and efficiency are crucial for meeting the demands of complex and time-sensitive projects. At GCH Process, we leverage cutting-edge 5-axis CNC machining technology to provide exceptional machining services that cater to the intricate requirements of modern industries. Our state-of-the-art 5-axis machines enable us to produce high-quality parts with superior accuracy and speed, making us a trusted partner for your most challenging machining needs.

Advantages of 5-Axis CNC Machining

1. Accelerated Production Times

5-axis CNC machining stands out for its ability to significantly reduce production times. At GCH Process, our advanced 5-axis machines, including the latest models from HAAS and other leading brands, are designed for rapid prototyping and production. With multiple machines in-house, we ensure quick turnarounds for both prototype and end-use parts, allowing us to meet tight deadlines without compromising quality.

2. High-Precision Equipment

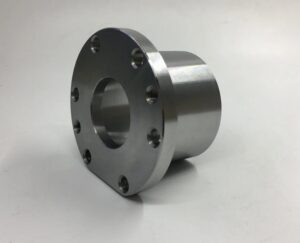

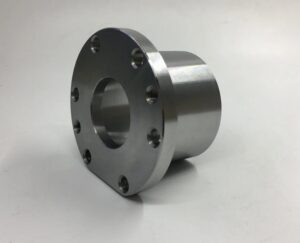

Our commitment to excellence is reflected in the high-quality machinery we use. GCH Process employs top-tier 5-axis CNC machines equipped with precise inspection systems that guarantee tight tolerances. This high level of precision is essential for applications requiring exacting standards, such as aerospace components and high-tech electronics.

3. Extensive Expertise

With years of experience in the machining industry, our team at GCH Process possesses in-depth knowledge of material properties and machining techniques. This expertise allows us to handle even the most complex parts efficiently, ensuring that every project is executed with precision and reliability.

4. Versatility Across Industries

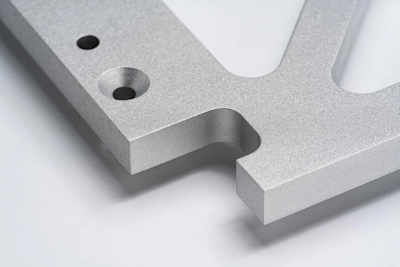

5-axis CNC machining is versatile and applicable across various industries. From aerospace to electronics, GCH Process has successfully delivered high-quality parts for diverse sectors. The ability to create intricate geometries makes 5-axis machining ideal for components such as aircraft bulkheads, fuselage sections, and electronic enclosures.

Understanding the 5-Axis Machining Process

5-axis CNC machining represents a significant advancement over traditional 3-axis systems. Unlike conventional machines where the cutting tool moves along three axes—X, Y, and Z—5-axis machines introduce two additional rotational axes. These axes enable the cutting tool to approach the workpiece from virtually any angle, enhancing the capability to produce complex shapes and intricate details.

1. Reduced Setup Time

One of the major advantages of 5-axis machining is the reduction in the number of setups required. The ability to access multiple angles without repositioning the workpiece streamlines the machining process, leading to faster production and reduced potential for errors.

2. Enhanced Accuracy

The increased flexibility of 5-axis machining not only improves the ability to create complex parts but also enhances the overall accuracy of the final product. By minimizing the need for manual adjustments and re-fixturing, our machines at GCH Process ensure consistent and high-precision results.

Types of 5-Axis Machining

1. Simultaneous 5-Axis Machining

Simultaneous, or continuous, 5-axis machining allows for dynamic adjustments across all five axes simultaneously. This method is ideal for high-speed applications and complex parts, as it eliminates interruptions in the machining process, resulting in faster production cycles and smoother finishes.

2. 3+2-Axis Machining

In contrast, 3+2-axis machining involves the use of the additional axes (typically A and B) only when the cutting tool is not moving along the primary X, Y, and Z axes. While this method may be slower than simultaneous machining, it can offer advantages in terms of tool rigidity and longer tool life, making it suitable for certain applications.

Machine Configurations: Trunnion-Style vs. Swivel-Rotate-Style

1. Trunnion-Style Machines

Trunnion-style 5-axis machines feature a moving table that allows the workpiece to be positioned at various angles. This design enhances access to undercuts and heavy material removal. The A-axis and C-axis configurations provide a larger work envelope, making these machines well-suited for large or intricate parts.

2. Swivel-Rotate-Style Machines

Swivel-rotate-style machines utilize a rotating spindle to achieve additional axes of movement. The B-axis and C-axis configurations enable precise cutting from different angles while maintaining a stationary table. This setup is advantageous for handling heavy parts and reducing vibration, which improves accuracy and surface finish.

5-Axis Machining FAQ

What are the five axes in CNC machining?

In 5-axis CNC machining, the five axes refer to the three-dimensional movements of the cutting tool along the X, Y, and Z axes, plus two additional rotational axes. These additional axes enable the tool to approach the workpiece from various angles, allowing for more complex machining operations.

When is 5-axis machining necessary?

5-axis machining is ideal for creating highly complex and detailed parts that require precise geometries and tight tolerances. Its flexibility makes it suitable for applications where traditional 3-axis machines may fall short in terms of accuracy and efficiency.

Can 5-axis machining achieve tight tolerances?

Yes, 5-axis CNC machining is capable of producing parts with extremely tight tolerances. The advanced technology and precise control offered by 5-axis machines ensure that even the most detailed and complex components meet stringent specifications.

At GCH Process, we are dedicated to delivering top-tier 5-axis CNC machining services that meet the highest standards of precision and quality. Our expertise, state-of-the-art equipment, and commitment to customer satisfaction make us the ideal partner for your most demanding machining projects. Contact us today to discover how our 5-axis CNC machining services can enhance your manufacturing processes.