High precision machining is a specialized manufacturing process that produces metal components with exceptionally tight tolerances. Utilizing advanced CNC machines, this process ensures the creation of highly accurate and consistent parts, which is essential in industries such as automotive, aerospace, electronics, and medical.

In this article, we will explore the benefits of high precision machining and discuss the various types of services offered by GCH Process.

What is High Precision Machining?

High precision machining refers to machining processes that produce parts with very tight tolerances and high accuracy. While there are no universally defined tolerance ranges for high-precision parts, the complexity and volume of the order often determine the level of precision required.

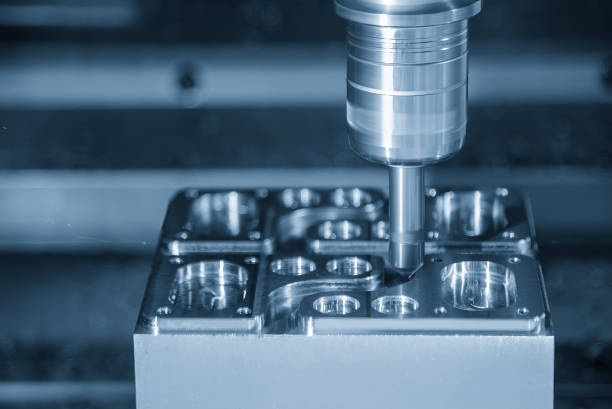

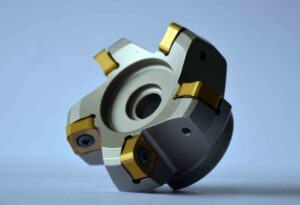

High precision machining is a subtractive process, meaning material is removed from a workpiece using cutting tools. This contrasts with additive processes such as welding or casting, where material is added. The precision and consistency achieved through high precision machining make it essential for producing parts that meet exact specifications.

The Role of Tolerances in High Precision Machining

Tolerance is a crucial concept in precision machining. It refers to the permissible limit or limits of variation in a physical dimension. In high precision machining, tolerances are extremely tight, often within the range of ±0.001 inches or less. Such stringent tolerances ensure that each part fits perfectly in its intended application, which is especially important in industries where even minor deviations can result in significant failures.

For example, in the aerospace industry, parts must fit together with extreme precision to ensure the safety and performance of the aircraft. Similarly, in the medical field, devices and implants must be manufactured to exact specifications to function correctly and safely within the human body.

Applications of High Precision Machining

High precision machining is vital for manufacturing parts that demand tight tolerances and high accuracy. Industries such as automotive, aerospace, and medical heavily rely on this process because even minor flaws in machined parts can lead to catastrophic consequences. For instance, an aerospace component must function flawlessly during flight, and a medical device must operate reliably to ensure patient safety. The consistent precision offered by computer-controlled machines guarantees the reliability of these critical components.

Indústria automóvel

In the automotive industry, high precision machining is used to produce engine components, transmission parts, and other critical elements that require exact dimensions to ensure optimal performance and safety. Precision machining ensures that parts such as pistons, cylinders, and gearboxes are manufactured to the highest standards, reducing the risk of mechanical failure and enhancing the overall efficiency of the vehicle.

Indústria aeroespacial

The aerospace industry demands the highest levels of precision and reliability. High precision machining is used to manufacture various components, including turbine blades, structural elements, and fasteners. These parts must withstand extreme conditions and stresses, making precision machining essential for ensuring their durability and performance.

Indústria médica

In the medical field, high precision machining is used to produce surgical instruments, implants, and other medical devices that require exact specifications. For example, orthopedic implants must be manufactured with extreme precision to fit perfectly within the human body and function correctly. Similarly, surgical instruments must be produced to exact dimensions to ensure their effectiveness and safety during medical procedures.

Indústria eletrónica

High precision machining is also crucial in the electronics industry, where components must be manufactured with tight tolerances to ensure proper functioning. Precision machining is used to produce parts such as connectors, housings, and heat sinks that require exact dimensions and high-quality surface finishes.

Benefits of High Precision Machining

High precision machining offers numerous benefits, including:

1. Exceptional Accuracy and Consistency: The primary advantage of high precision machining is its ability to produce parts with very tight tolerances and high accuracy. This is crucial for applications where precision is paramount.

2. Enhanced Adjustability: In industries such as automotive and medical, where quality is critical, machining allows for more precise dimensions than casting. Parameters can be adjusted as needed without the need for recasting, offering greater flexibility and control.

3. Superior Surface Finish: High precision machining provides an excellent surface finish while maintaining the quality and accuracy of the component. This is essential for applications where a smooth surface is required, such as in electronics and aerospace manufacturing.

4. Improved Efficiency: Precision machining reduces the need for secondary operations, such as grinding or polishing, by producing parts with high-quality finishes directly from the machine. This reduces production time and costs, enhancing overall efficiency.

5. Increased Durability: High precision machining ensures that parts are manufactured to exact specifications, reducing the risk of mechanical failure and increasing the durability of the final product. This is particularly important in industries where component failure can have severe consequences.

High Precision Machining Services

High precision machining encompasses various CNC machining and screw machining services. At GCH Process, we offer a comprehensive range of services, including:

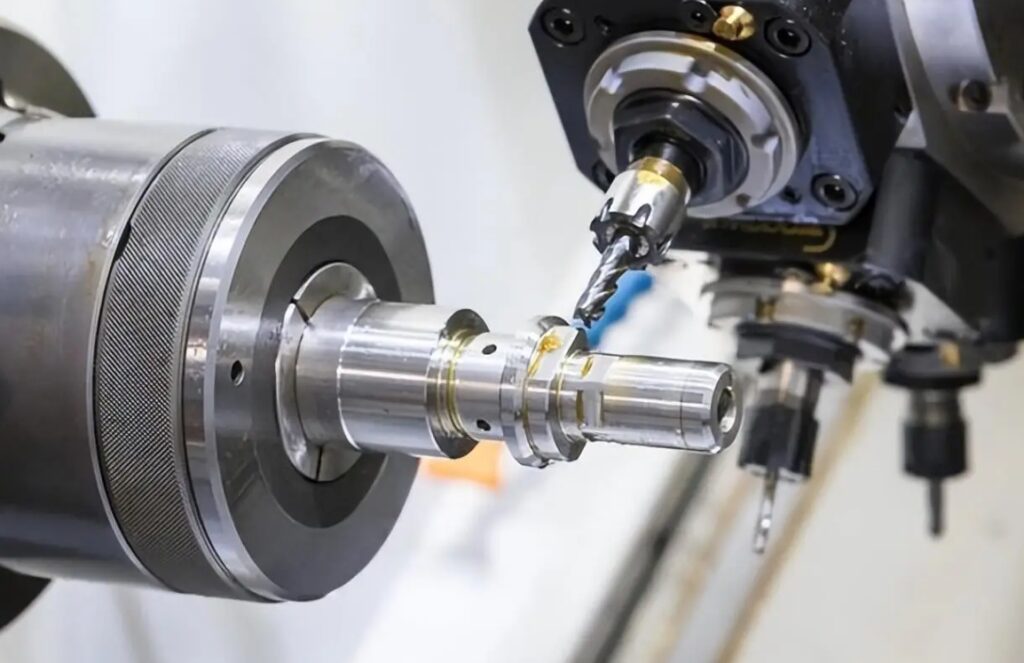

CNC Multi-Spindle Machining

CNC multi-spindle machining is ideal for producing complex parts with multiple features. This process involves multiple spindles operating simultaneously, allowing for the efficient production of intricate components. Multi-spindle machines can significantly reduce production time and costs, making them an excellent choice for high-volume manufacturing.

Automatic Bar Machining

Automatic bar machining is an efficient method for high-volume production of precision components. This process involves feeding bars of material into the machine, which then automatically machines the parts to the desired specifications. Automatic bar machining is ideal for producing small to medium-sized parts with tight tolerances.

CNC Turning & Milling

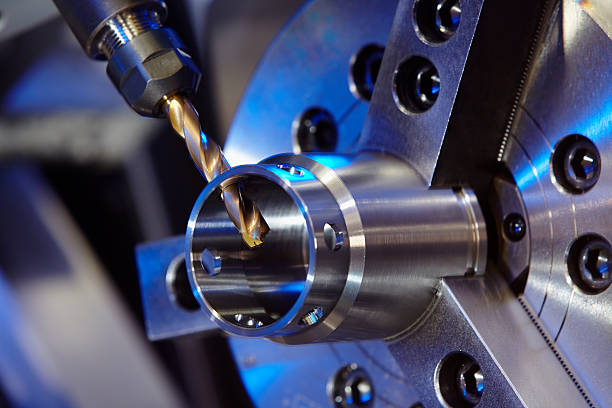

CNC turning and milling are versatile processes for creating intricate parts with tight tolerances. CNC turning involves rotating the workpiece while a cutting tool removes material, making it ideal for producing cylindrical parts. CNC milling, on the other hand, involves rotating the cutting tool while the workpiece remains stationary, allowing for the production of complex shapes and features.

Multi-Spindle Screw Machining

Multi-spindle screw machining is suitable for high-speed production of small, precise parts. This process involves multiple spindles operating simultaneously, each equipped with a cutting tool. Multi-spindle screw machines can produce large quantities of parts quickly and efficiently, making them ideal for high-volume manufacturing.

Swiss Screw Machining

Swiss screw machining is perfect for producing small, intricate components with high precision. This process involves feeding the workpiece through a guide bushing, which supports the material close to the cutting tool. This minimizes deflection and allows for the production of parts with very tight tolerances.

In addition to these services, GCH Process provides consulting and engineering support, as well as secondary and value-added operations such as washing, packaging, plating, heat treating, grinding, and assembly. Our comprehensive capabilities ensure that we can meet the diverse needs of our clients, from prototyping to large-scale production.

Conclusão

High precision machining is essential for producing high-quality components with exact specifications. Its ability to deliver parts with tight tolerances, superior surface finishes, and adjustable dimensions makes it indispensable in various high-stakes industries. At GCH Process, our expertise in high precision machining allows us to handle orders of any size and complexity, ensuring consistent and reliable results. Contact us today to learn more about our high precision machining services and how we can support your manufacturing needs.

Read Next: High Volume Precision Turned Parts FAQ

By focusing on the precise requirements and standards of high precision machining, GCH Process stands out as a leader in delivering high-quality, reliable components across various industries. Our commitment to excellence and advanced technology ensures that we meet and exceed our clients’ expectations.