Hey there, car enthusiasts and fellow engineers! Today, let’s dive into a topic we all use daily but rarely explore in depth – how car parts transform from design to reality. As an engineer who’s been in the automotive trenches for years, I can tell you this process is nothing short of an exciting adventure! And the star of this adventure? Maquinação CNC.

The Magic of Manufacturing

Let’s jump right into the heart of it all – the manufacturing stage. This is where the magic happens! CNC machining technology really shines here, especially our two superstars: CNC turning and precision machining.

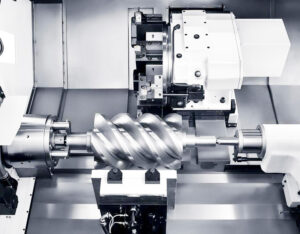

Torneamento CNC

Picture this as a spa treatment for cylindrical parts. The material spins gracefully while the cutting tool, like a skilled masseuse, precisely sculpts the shape we need. This is how shafts and hubs are born, parts almost every car can’t do without.

Why is CNC turning so awesome? It’s like a perfectionist, accurate to a mind-blowing degree. Parts fit together like they were made for each other – which, well, they were! Plus, CNC machines are so fast, we can keep up with market demands while maintaining top-notch quality.

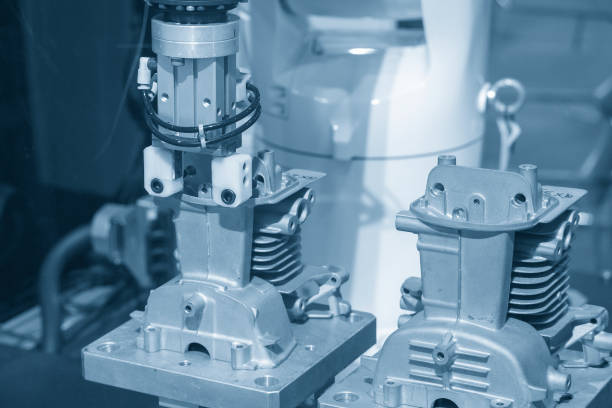

Maquinação de precisão

If CNC turning is a sculptor, precision machining is a micro-engraving master. It creates parts so complex they’ll make your head spin, like engine blocks and braking systems. How precise are we talking? Let’s just say it’ll make your jaw drop.

Why is this so crucial? In the automotive world, quality is life. Every part must strictly meet safety and performance standards. Even better, precision machining helps us save materials, making our production process more eco-friendly. Cool, right?

Design: Where It All Begins

But hold on, before we start manufacturing, there’s a key step – design. Every awesome car part starts with a brilliant design. Engineers first sketch out ideas, then use CAD software to turn these ideas into precise specifications. Trust me, this stage is super important. A good start is half the battle – who wants trouble mid-production?

How great is using CNC technology in design? It’s like fitting our models with a translator, directly turning designs into manufacturing instructions. This greatly reduces the risk of human error, bringing us one step closer to the perfect part.

Quality Control: Strict to a Fault

After manufacturing, parts don’t just race to the assembly line. They go through a series of quality checks so strict they’re almost harsh. We have automated inspection systems seamlessly connected to CNC machines, reporting on dimensions and surface finishes in real-time. It’s like giving each part its own personal bodyguard, ensuring they’re all flawless.

Real-World Application: The Ultimate Test

Now, let’s see how these parts perform in real life. CNC machined parts can be found in various car systems:

Engines

Precision parts like pistons and crankshafts determine a car’s performance and reliability.

Transmissions

CNC turning shines here, producing gears that make shifting as smooth as silk.

Suspension Systems

Carefully crafted parts make your ride stable and comfortable, like floating on a cloud.

These parts don’t just need to fit perfectly; they need to work flawlessly together. It’s the reliability of CNC machined parts that allows us to build cars drivers can trust.

Embracing Innovation: Never Standing Still

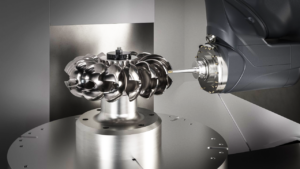

The automotive industry never rests on its laurels. As engineers, we’re always looking for ways to improve efficiency and reduce costs. CNC machining technology is our trusty sidekick, constantly pushing boundaries and opening new possibilities.

Take 5-axis CNC machining technology, for instance. It’s a real game-changer. It allows us to produce even more precise and complex parts while maintaining our high standards.

Even cooler, we’ve added smart technologies to our CNC systems. This not only boosts production efficiency but also provides us with valuable data for continuous improvement. It’s like giving machines a super-brain!

Conclusão

The journey of automotive parts from design to application is complex yet exhilarating. CNC machining technology, especially CNC turning and precision machining, plays a central role in this process.

Understanding the relationship between these technologies is crucial for everyone in the industry. As we continue to embrace new technologies, we’re paving the way for safer, more reliable, and higher-performing vehicles of the future.

At the end of the day, it’s not just about making parts; it’s about creating vehicles we can trust. That’s the ultimate goal for us engineers – a perfect integration of design, manufacturing, and functionality.

In this rapidly evolving industry, choosing the right partner is crucial. That’s why I want to give a special shout-out to our company – GCH Process. As an IATF:16949 certified source CNC factory, we have a unique advantage in the automotive parts manufacturing field. We don’t just understand the entire process; more importantly, we have the capability to turn these concepts into high-quality products. Whether you’re looking for precision parts or large-scale production solutions, GCH Process can meet your needs, bringing exceptional quality and efficiency to your projects. Let’s work together to build the future of the automotive industry!