Alumínio 6061, a widely used alloy in the 6000 series, is renowned for its strength, corrosion resistance, and excellent machinability. Its versatility makes it a preferred choice across industries like aerospace, automotive, electronics, and medical devices. However, selecting the right manufacturing process for aluminum 6061 parts is critical for balancing cost-effectiveness with the high quality standards these sectors demand.

This article provides a detailed cost-effectiveness analysis of two key manufacturing techniques: extrusion combined with post-machining and full CNC machining. By addressing factors like design complexity, production volume, and economic trade-offs, we aim to guide manufacturers in making informed decisions tailored to their needs.

Material Properties and Design Considerations

Before diving into process selection, it’s important to understand the properties of aluminum 6061 that impact manufacturing decisions. This alloy offers:

- Moderate Strength: Sufficient for many applications but lower than some high-strength alloys or steels.

- Resistência à corrosão: Ideal for environments requiring durability.

- Good Machinability: Facilitates efficient production.

Design Complexity

The design intricacies of a part—its geometry, tolerance, and surface finish—significantly influence costs and feasibility:

- Simple Geometries: Best suited for extrusion, which minimizes waste and production costs.

- Geometrias complexas: Often require CNC machining due to its precision and ability to handle intricate designs.

These considerations form the foundation for selecting the most suitable manufacturing method.

Detailed Process Descriptions

A. Extrusion with Post-Machining

Extrusion is a process where a heated aluminum billet is forced through a die to create a continuous profile of a specific shape.

Vantagens:

- Material Utilization: High efficiency with minimal waste.

- Cost-Effectiveness for High Volumes: Automated operations lower per-unit costs as production scales.

- Streamlined Production: Especially beneficial for standard profiles and large production runs.

Desvantagens:

- Die Costs: Custom die creation can cost thousands of dollars, impacting low-volume production.

- Precision Limitations: Typical tolerances range from ±0.2mm to ±0.5mm, requiring post-machining for tighter tolerances.

- MOQ Constraints: Minimum order quantities often range from 2,500 to 5,000 lbs, which may not suit small-scale projects.

- Geometry Restrictions: Complex shapes may require expensive or technically challenging die designs.

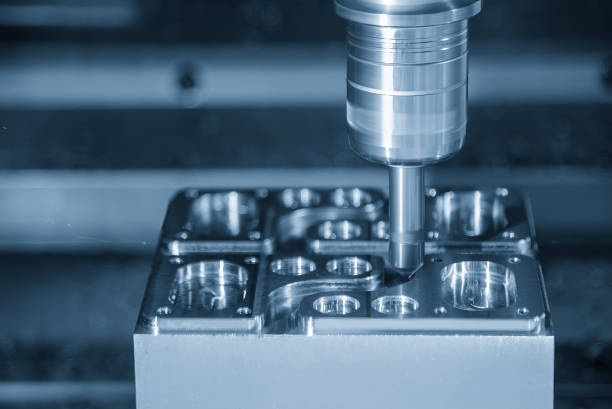

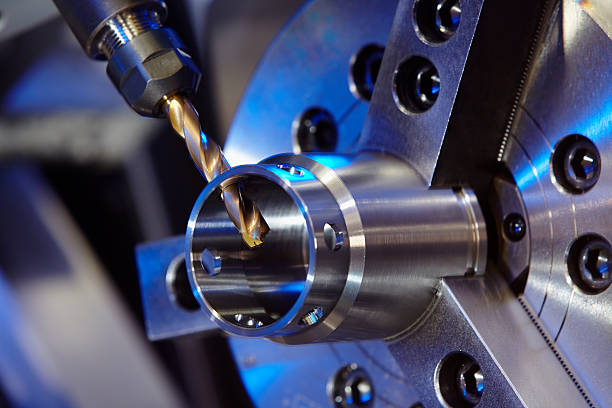

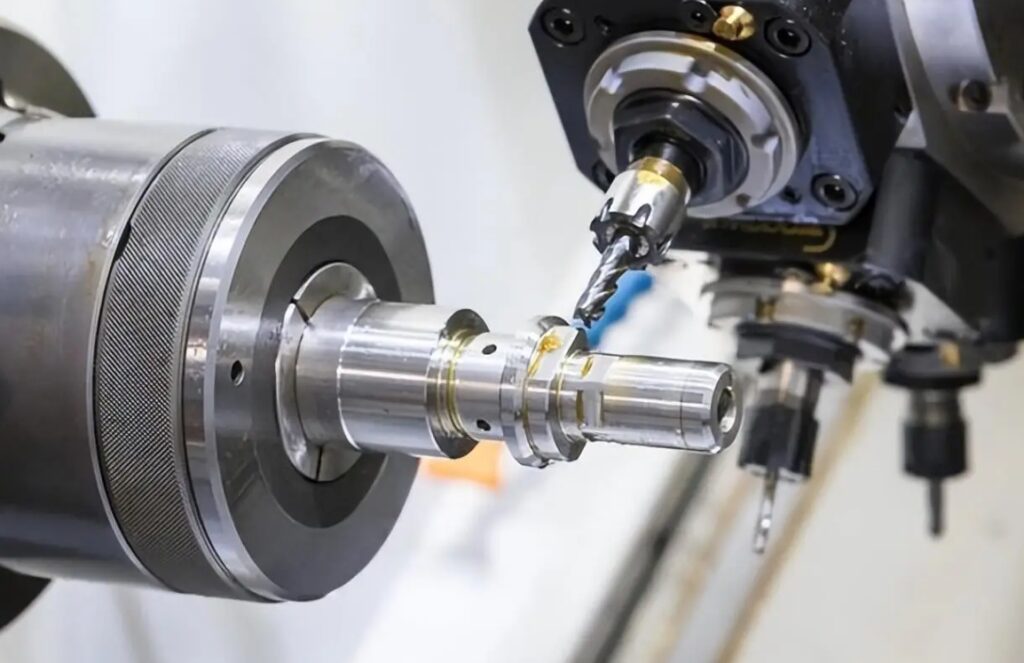

B. Full CNC Machining

CNC machining removes material from a solid block to produce highly precise parts based on preprogrammed designs.

Vantagens:

- Alta precisão: Achieves tolerances as tight as ±0.05mm or better.

- Design Flexibility: Handles intricate and complex geometries with ease.

- Low Volume Feasibility: Ideal for small production runs or custom designs.

Desvantagens:

- Resíduos de materiais: Higher waste compared to extrusion.

- Higher Per-Unit Costs: Especially for large production runs.

- Time-Intensive: Increased labor and machine time contribute to costs.

Cost Analysis

A thorough cost analysis requires evaluating:

- Custos de material: Including waste generated during production.

- Tooling Costs: Custom dies for extrusion vs. tooling for CNC.

- Processing Costs: Labor, energy, and equipment usage.

Below is a cost comparison for producing a moderately complex aluminum 6061 part:

| Production Quantity | Full CNC Machining (USD/unit) | Extrusion + Post-Machining (USD/unit) | Notas |

|---|---|---|---|

| 500 | $12.00 | $8.50 | High die amortization benefits extrusion. |

| 1,000 | $12.00 | $7.00 | Die amortization lowers costs further. |

| 5,000 | $12.00 | $5.00 | Significant cost advantages for extrusion. |

| 10,000 | $12.00 | $4.50 | Extrusion becomes highly economical. |

IV. Alternative Manufacturing Processes

In addition to extrusion and CNC machining, alternative methods may suit specific needs:

- Investment Casting: Enables intricate shapes but generally has looser tolerances than CNC machining.

- Fundição injectada: Efficient for high-volume production but may require post-finishing.

- Impressão 3D: Offers unmatched design freedom but is costlier and less precise for high-volume runs.

Each method should be evaluated based on the specific requirements of the project.

Conclusão

The choice between extrusion with post-machining and full Maquinação CNC depends on factors like:

- Production Volume: Extrusion excels in high-volume scenarios, while CNC is better for low-volume or custom parts.

- Design Complexity: CNC is unmatched for intricate geometries and tight tolerances.

- Budget Constraints: Extrusion often delivers better cost efficiency for simpler designs.

For large-scale, straightforward designs with moderate tolerances, extrusion offers substantial cost savings. Conversely, CNC machining is ideal for complex, precision-demanding parts in low volumes. Exploring alternative processes like investment or die casting may provide further options, especially for unique requirements.

Ultimately, manufacturers should conduct a comprehensive cost analysis tailored to their specific project needs to make an informed decision.