Laser Cutting Service

- Lead time as fast as 3-5 days

- ISO 9001:2015 certificated

30t-1800t

Instant Quotes

12

Surface Finishes

0pc

MOQ

0.025mm

Tolerances

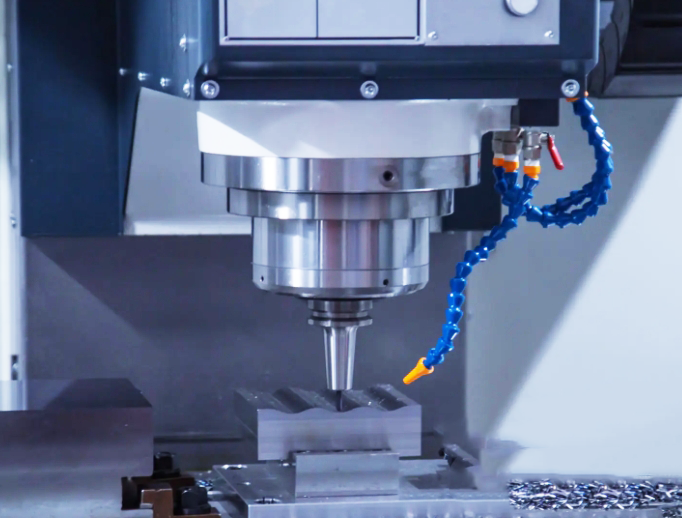

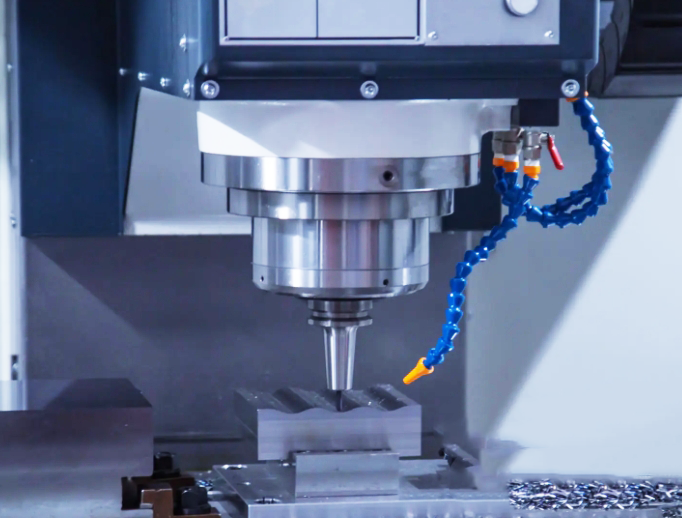

Our Custom Laser Cutting Service

Backed by outstanding manufacturing capabilities and 10+ years of industry experience, gch offers superior quality custom laser cutting services with excellent result potential. We combine highly skilled machinists with cutting-edge laser cutting facilities to cut anything from delicate aluminum foils to thick steel sheets. Enjoy metal laser cutting service with an extensive range of advanced processes and technology.

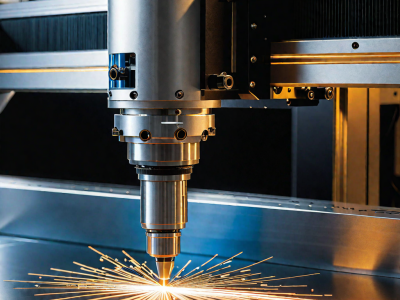

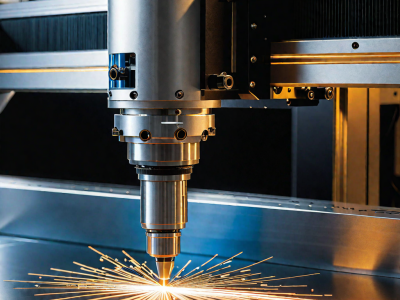

Advantages of Laser Cutting

Laser cutting offers several benefits for many industries, ranging from precision, speed, repeatability, and flexibility. GCH’s laser cutting service help meet industry requirements in terms of functionality and aesthetics.

- High Precision Cuts: The light beam involved in laser cutting ensures high-precision melting and evaporation of materials, ensuring accuracy as low as 0.003mm.

- Maximum Sheet Utilization: The laser cutting technology maximizes the number of usable metal sheets and gives little room for wastage, ensuring that only the exact amount of material is provided.

- High Cutting Versatility: With advanced laser cutting operations, you can get custom laser cut parts with simple cuts, marking, engravings, and complex, intricate details.

- Low Power Use: Sheet metal laser cutters effectively cut out material pieces without consuming too much energy, often using just 10kW of energy.

- Little to No Damage: The heat from laser cutting processes affects very minimal areas on the component and has no effect on the tolerance of the laser cutting parts.

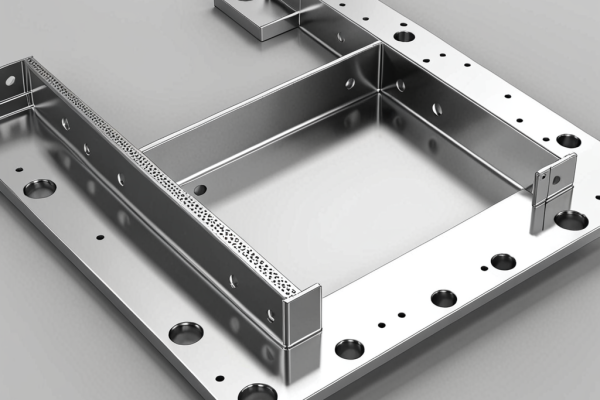

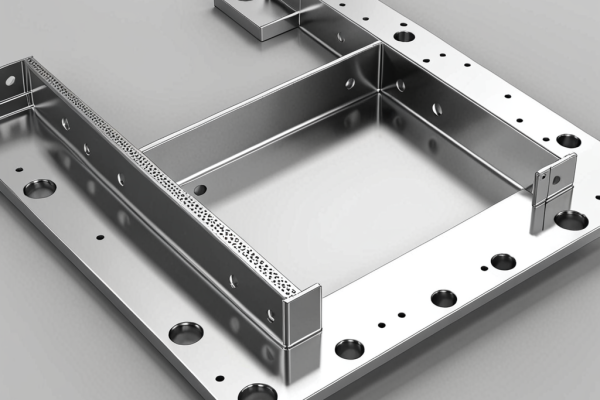

Laser Cutting From Prototyping to Production

The versatility and precision of laser cutting ensure excellent initial product development and continuous production. Design files are rapidly turned into end products, from intricate custom parts to complex enclosures.

Preparation of Blanks

GCH uses high-precision laser cutters to create material blanks and prepare flat patterns for prototyping and production.

Rapid Prototyping

Compatibility with various materials, production speed, and low cost per unit make GCH’s laser cutting services ideal for creating prototypes of end products.

GCH Laser Cutting Capabilities

GCH’s custom overmolding services ensure the creation of plastic parts that look and perform better. Our production line consists of an overmolding injection molding process that allows us to combine several different materials into one, ensuring you get superior-quality products.

| Standards | Description |

| Minimum part size | 10 mm (0.40 in.) |

| Minimum feature size | 2X material thickness with a minimum of 1 mm (0.04 in.) |

| Distance dimensions | Our laser cutting standards depend on ISO 2768-c. Typical size: +/- 0.2 mm (0.008 in.) for length, width, diameter and location. |

| Maximum material thickness | Carbon steel < 25 mm (0.98 in.), Stainless steel < 15 mm (0.59 in.), Aluminum < 15 mm (0.59 in.) , Copper < 12.7 mm (0.5 in.) |

| Kerf (slit size) | About 0.5 mm (0.02 in.) |

| Edge condition | Laser cut edges have matte and vertical lines. |

| Laser sources | CO2 and fiber lasers. Up to 10 kW. |

| Repeatability | +/- 0.05 mm (0.002 in.) |

| Positioning accuracy | +/- 0.10 mm (0.004 in.) |

| Lead Time | 5-7 days |

Laser Cutting Materials

GCH’s laser cutting service is versatile and compatible with various materials, ranging from ferrous to non-ferrous metals, plastics, and other non-metals. Our laser cutting facility combines ultra-modern technology with skilled professionals to laser cut materials across different strengths, weights, and thermal properties. Here are some laser cutting materials available for your project.

Metals

Take advantage of our wide availability of metal materials for your laser cutting project. Our production-grade metals come with high strength and durability, optimal thickness, and customizability. As the most common laser cutting materials, GCH offers a long list of metals, including:

Types:

Aluminum

Stainless steel

Steel

Copper

Plastics

There are also many compatible plastics with the laser cutting process. We offer a wide range of plastics that can meet simple commercial applications and complex industrial requirements. GCH’s production-grade plastics are excellent options for medical instruments, gear, food packaging, and more. The common ones include:

Types:

PMMA

Delrin (POM, Acetal)

Polyethylene

Polypropylene

Styrene

Lucite

Mylar (polyester)

Acrylic

Our acrylic laser cutting service is extensively valuable, helping you meet industry demands for various applications. Our improved technology allows us to cut and engrave on acrylic materials to achieve the best results. GCH offers both cast acrylic materials and extruded acrylic to meet your production requirements.

Finishing Options for Laser Cutting

Improve the surface quality of your plastic injection molded parts with superior surface finishing options. GCH provides an extensive list of surface treatments to improve the aesthetic appeal of your products. These efficient secondary operations also improve the mechanical qualities of prototypes and production parts.

| Name | Materials | Color | Texture | Thickness | |

| Anodizing | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | A thin layer: 5-20 µm Hard anodic oxide film: 60-200 µm |

| Beed Blasting | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte | 0.3mm-6mm |

| Powder Coating | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | 5052 Aluminum 0.063″-0.500” 6061 Aluminum 0.063″-0.500” 7075 Aluminum 0.125”-0.250″ Mild Steel 0.048″-0.500” 4130 Chromoly Steel 0.050″-0.250” Stainless Steel 0.048″-0.500” |

| Electroplating | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish | 30-500 µin |

| Polishing | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy | N/A |

| Brushing | Aluminum, Brass, Stainless Steel, Steel | Varies | Satin | N/A |

| Silkscreen Printing | Aluminum, Brass, Stainless Steel, Steel | Varies | N/A | < 1 µm |

| Passivation | Stainless Steel | None | Unchanged | 5μm – 25μm |

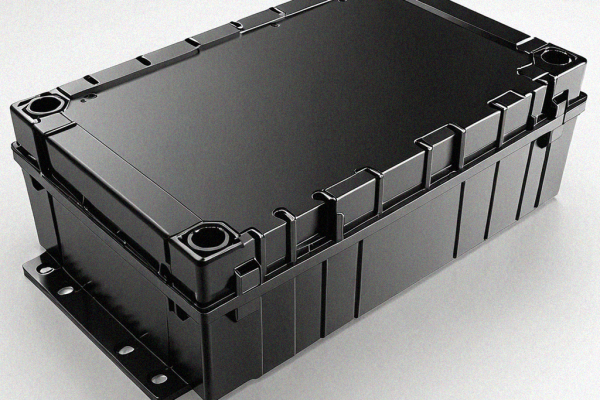

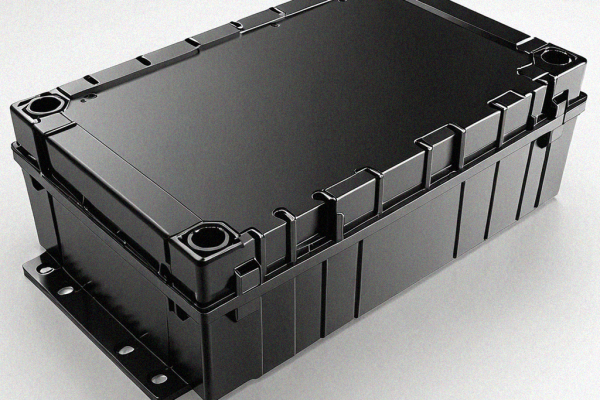

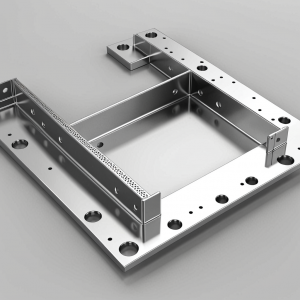

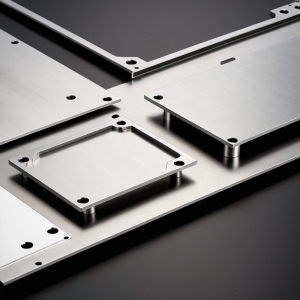

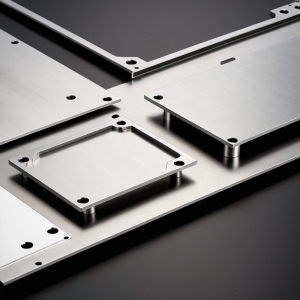

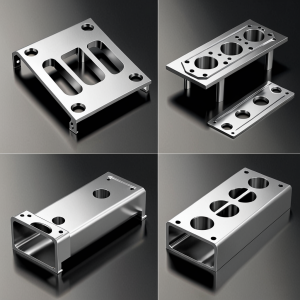

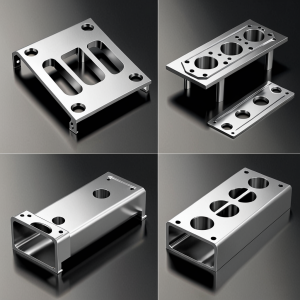

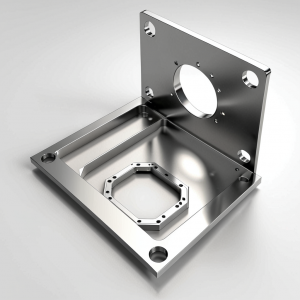

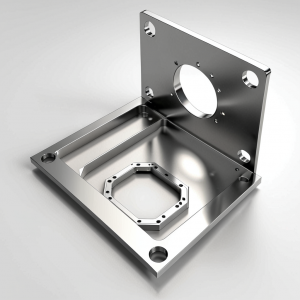

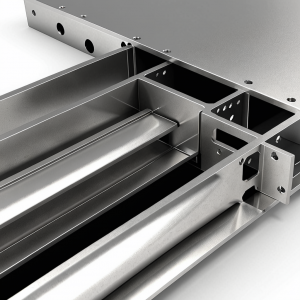

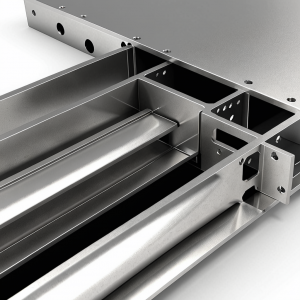

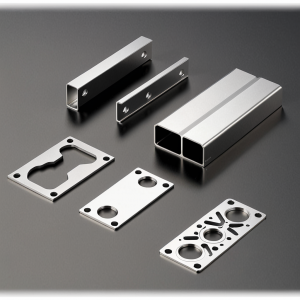

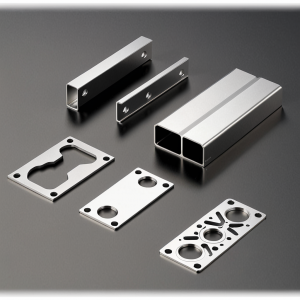

Gallery of Sheet Metal Laser Cutting Parts

Why Choose GCH

We take an approach that aims to meet your customized needs. We aim to provide long-term prototype overmolding solutions to engineering experts and project managers from design to production. GCH combines cost-effective mold tooling with tech-driven overmolding services that help to make high-quality parts.

No MOQ

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced injection molding cost.

Tight Tolerance and High Quality

Our plastic injection molding process includes vital design considerations to improve moldability and enhance aesthetic appearance. GCH delivers plastic injection molded parts of varying sizes and complexities. Our standard tolerances are defined by ISO 2768 standards, helping us meet tight tolerance requirements.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Injection Molding Specialists

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

How Custom Laser cutting Works?

The injection molding process involves feeding raw plastic materials into an injection molding machine, melting them down, and then injecting them into an aluminum or steel mold. Upon cooling, a production-grade thermoplastic part is formed and ejected for further use or assembly.

Laser Cutting for Various Applications

Dive into GCH’s extensive gallery that showcases some of our completed injection molded parts and take confidence that we can create your injection molding project according to your strict specifications.

The FAQ

Frequently Asked Questions

Our laser cutting process is compatible with a wide variety of materials, including ferrous and non-ferrous metals, plastics, and other non-metals. We can also cut materials with varying weights, thicknesses, and mechanical properties.

Our laser cutting service can cut material with a precision of +/- 0.002 inches and a positional accuracy of +/- 0.004 inches.

GCH has different thickness specifications for different laser cutting materials. The maximum thickness for stainless steel and aluminum is < 15 mm. On the other hand, we can cut carbon steel up to 25 mm thick and less than 12.7 mm for copper.

Yes, our experts have adequate experience and knowledge of laser engraving and etching. Therefore, we are able to provide superior quality services that will meet your demands.

Yes, you can bend the material with the various bending techniques offered at GCH. There is an allowance for bending in your flat pattern profiles. We offer sheet metal bending techniques like V-bending, roll bending, rotary bending, wipe bending, and so on. The technique used will depend on your specific applications.

Laser cutting is a highly efficient method that can cut steel materials with a cutting speed of 600 inches per minute. This ensures multiple cutting projects will be completed quickly while also saving material costs. With our precise laser cutting machines, you can be sure of faster lead times and reasonable pricing.

Latest Posts

Understanding CNC Machining: A Beginner’s Guide

Precision CNC machining services for custom parts. High-quality, accurate, and efficient solutions for various industries.

Top Materials Used In CNC Machining: A Comprehensive Guide

Precision CNC machining services for high-quality, custom parts. Expert manufacturing for industrial applications.

The Latest Trends In CNC Machining Technology You Should Know

“Precision CNC machining manufacturer offering high-quality custom parts, rapid prototypes, and production services for aerospace, automotive, medical, and industrial applications.”