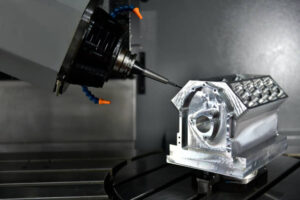

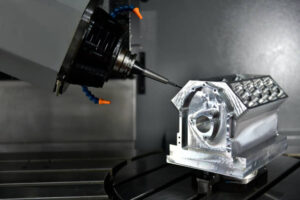

Imagine a world where machines work with surgical precision, guided by digital blueprints. This is the realm of Usinage CNC, a marvel of precision and automation. At its core lie two fundamental processes: drilling and tapping. These seemingly simple operations form the foundation of many complex CNC projects.

The Art of Precision Drilling

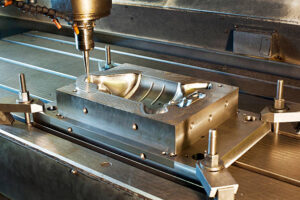

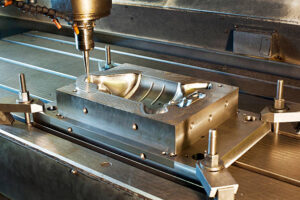

Think of a CNC machining center as a master craftsman capable of creating intricate designs with astounding accuracy. Drilling creates holes in workpieces, often the first step in many CNC projects. The drill bit, like a miniature spear, penetrates the material under the precise guidance of the CNC machine, resulting in perfectly formed holes ready for the next phase of machining.

Beyond Simple Holes

While drilling may seem straightforward, it opens up a world of possibilities. Consider the various diameters and depths of holes, their strategic placement, and the complex patterns that can be achieved. CNC machines, with their unmatched precision, make possible details that would be unattainable by hand.

Tapping: Creating Perfect Threads

If drilling creates holes, tapping transforms them by adding threads. Picture a screw with its spiral grooves carefully carved into a drilled hole. This is what happens during tapping. The CNC machine uses tapping tools to create these threads, converting a simple hole into a threaded one capable of accepting screws or other fasteners.

The Importance of Cutting Tools and Coolant

Success in drilling and tapping largely depends on the cutting tools and coolant used. Drill bits are carefully selected based on the material being drilled, coming in various materials, sizes, and tip geometries. Coolant plays a crucial role in lubrication, reducing friction and heat while ensuring smooth cutting and preventing tool wear.

Precision and Surface Finish Matter

In CNC machining, precision is everything. Every hole and thread must fall within strict tolerances. CNC machines achieve this precision through sophisticated control systems, ensuring components fit perfectly and function flawlessly. The surface finish achieved during drilling and tapping also plays a crucial role in determining the final quality of machined parts.

Efficiency Meets Quality

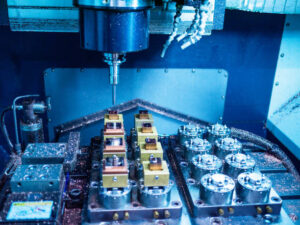

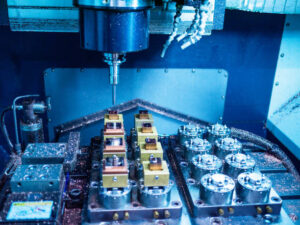

In the CNC world, efficiency and quality aren’t opposing forces – they complement each other. Efficient CNC processes, using optimized tools and techniques, contribute to higher quality products. Similarly, quality control measures ensuring accuracy and precision help improve manufacturing efficiency.

The Benefits of CNC Machining

The unmatched precision in drilling and tapping brings numerous advantages:

- Enhanced accuracy: Elimination of human error

- Improved efficiency: Faster production cycles

- Better quality: Precise control leading to superior components

- Versatility: Capability to handle various materials and sizes

- Repeatability: Consistent performance regardless of production volume

Looking to the Future

Usinage CNC has revolutionized manufacturing, offering levels of precision, efficiency, and quality that were unimaginable decades ago. As we move toward an increasingly automated and digital future, understanding these fundamental processes becomes crucial. They are the gateway to innovation, pushing the boundaries of design, engineering, and manufacturing.

The impact of cycle time and quality control in CNC machining can’t be overstated. Cycle time – the duration of drilling and tapping processes – directly affects production speed. While CNC machines are designed to optimize cycle times through efficient cutting paths and parameters, quality is never compromised. Strict quality control ensures every hole and thread meets required specifications.

From Simple to Complex: The Diversity of Tapping

What appears to be a simple additional step in tapping opens up numerous possibilities. It enables the creation of threaded holes for fasteners, making secure assembly possible. Think of complex gears, intricate assemblies, or miniature components – tapping makes it all possible.

Related Wikipedia links:

This transformation of manufacturing continues to evolve, promising even greater advances in precision, efficiency, and innovation. The future holds unlimited possibilities as CNC machining technology continues to develop and refine.