Introduction

In today’s competitive research and development (R&D) landscape, the demand for precision, speed, and flexibility is more critical than ever. From initial concept design to final testing, CNC (Computer Numerical Control) machining technology plays a pivotal role in the R&D process. Whether you require high-precision components, rapid prototypes to validate designs, or custom machining for specialized applications, choosing the right CNC machining partner is paramount to the success of your R&D projects. This article delves into the importance of Services d'usinage CNC, prototyping services, and custom R&D machining, guiding you on how to select the right partner to meet your unique needs.

CNC Machining Services: A Solid Foundation for Your R&D Projects

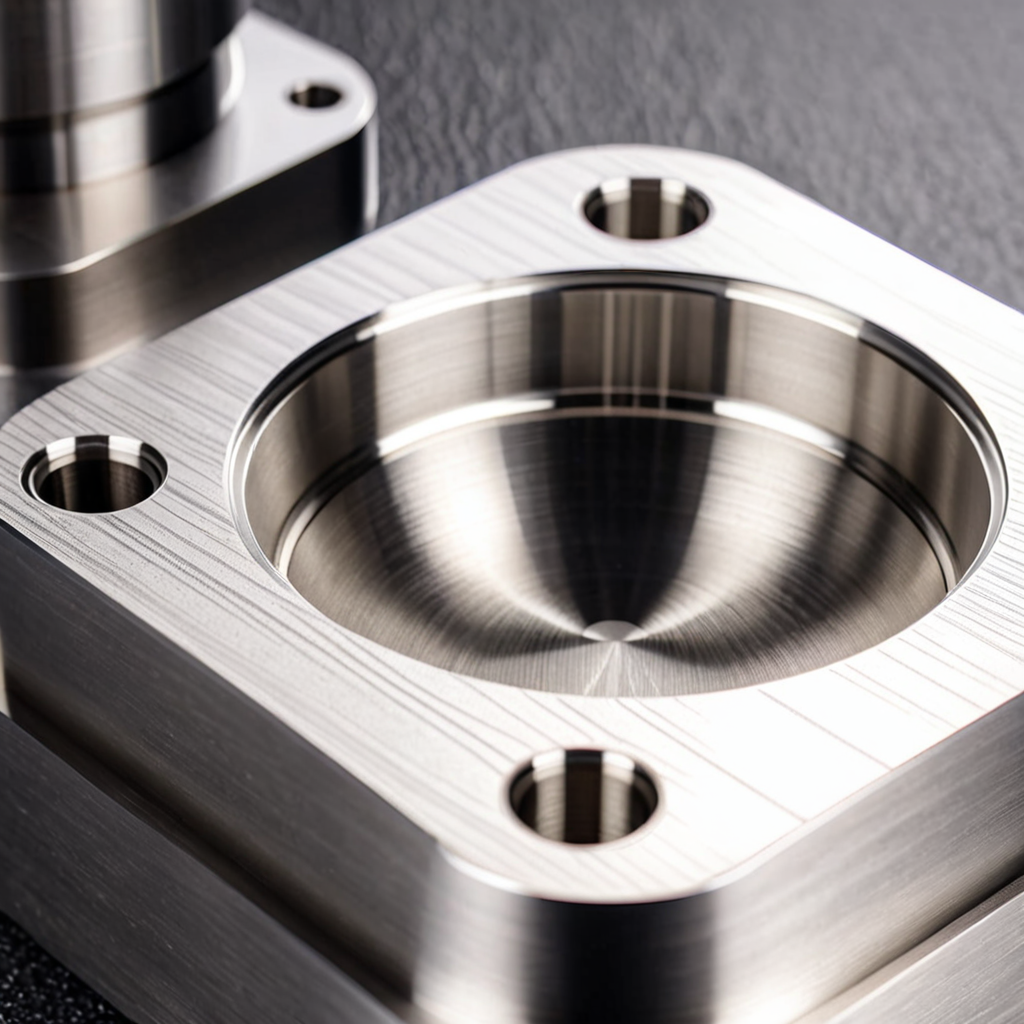

CNC machining services are an indispensable part of modern R&D. By using computer-controlled machines to precisely shape materials, CNC machining ensures the efficient and accurate production of intricate components. From aerospace to biotechnology, nearly every industry relies on CNC machining to produce high-quality parts for R&D, testing, and final products.

The Principles and Advantages of CNC Machining: At its core, CNC machining involves using pre-programmed computer instructions to control machine tools (such as milling machines, lathes, and grinders) for cutting operations. This approach enables a high degree of precision and repeatability, ensuring that produced parts meet strict dimensional and tolerance requirements.

CNC Machining Applications in R&D: In the R&D phase, CNC machining is widely used for manufacturing test fixtures, parts for experimental equipment, functional models, and more. For instance, aerospace engineers might use CNC machining to produce complex aircraft model components for wind tunnel tests. In the biotechnology sector, CNC machining can be used to produce high-precision medical device prototypes or microfluidic chips for research purposes.

Key Advantages of CNC Machining in R&D: The benefits of employing CNC machining in R&D include:

High Precision and Consistency: Accurate control guarantees parts meet design specifications for dimensions and shapes.

Rapid Production: CNC machines can produce parts quickly, shortening R&D cycles.

Complex Geometry Machining: Easily create complex structures that are hard to produce with traditional machining.

Polyvalence des matériaux : CNC machining can handle diverse materials, including metals, plastics, and composites.

CNC Prototyping Services: Rapidly Validate Your Design Ideas

Prototyping is a vital step in the R&D process, enabling engineers and designers to validate their concepts, identify potential issues, and make necessary improvements. CNC prototyping services use CNC machining technology to rapidly manufacture prototypes, providing an efficient solution for design verification.

The Importance of CNC Prototyping: Traditional prototyping methods can be time-consuming and costly. CNC prototyping, however, can produce high-precision prototypes in days or even hours, significantly reducing R&D timelines.

The CNC Prototyping Process: The typical CNC prototyping process includes:

Design Preparation: Engineers convert design drawings into programs readable by CNC machines.

Sélection des matériaux : Choosing materials based on the prototype’s functional and performance requirements.

Prototype Manufacturing: Using CNC machines to fabricate high-precision prototypes.

Prototype Testing: Evaluating the prototype’s functionality and performance.

Optimisation de la conception : Making adjustments and improvements based on testing results.

Key Advantages of CNC Prototyping:

Rapid Iteration: Quickly producing prototypes to support design iteration and optimization.

Functional Testing: Using real materials and manufacturing processes to simulate the final product’s performance.

Risk Reduction: Identifying and addressing design issues early, preventing major flaws in the mass production stage.

Custom CNC Machining for Research: Meeting Your Unique Needs

Every R&D project presents unique challenges and demands. Custom CNC machining for research provides flexible solutions to accommodate specialized requirements.

What is Custom CNC Machining? Custom R&D CNC machining refers to personalized services based on a client’s specific needs. This could include:

Special Material Machining: Processing unique alloys, ceramics, and composites.

Custom Sizes and Shapes: Manufacturing non-standard dimensions or complex geometric shapes.

Small Batch Customization: Providing small-scale production for R&D projects.

Special Surface Treatments: Applying specific surface finishes such as anodizing, sandblasting, and polishing.

Advantages of Custom CNC Machining:

Flexibilité : Meeting the unique needs of R&D projects.

Innovation Support: Enabling the realization of innovative ideas by handling specific requirements.

High Quality: Guaranteeing the production of parts that meet stringent quality standards.

Why Choose Us?

We offer years of experience in CNC machining, advanced equipment and technology, and a team of expert engineers. Our core strengths include:

State-of-the-Art CNC Machining Equipment: We utilize a variety of advanced CNC machines to accommodate diverse materials and machining needs.

Extensive R&D Project Experience: We have participated in numerous R&D projects, accumulating the know-how to understand and meet the unique demands of our clients.

Expert Engineering Team: Our team of skilled engineers provides customized solutions based on technical expertise.

Fast Response and Quality Customer Service: We value communication and offer prompt responses with excellent customer service.

No matter what stage your R&D project is at, we can provide professional CNC machining solutions. Contact us today to discuss your specific needs and discover how we can help bring your innovative ideas to life.

Conclusion

In the competitive world of R&D, selecting the right CNC machining partner is crucial. Services d'usinage CNC, prototyping services, and custom R&D machining can provide a strong foundation for your R&D projects, shortening development cycles, reducing costs, and helping you achieve your innovative goals.