CNC machining, a technology that utilizes precise computer control, has long become an essential part of modern industry. Whether it’s automotive parts, medical devices, or intricate instruments, CNC machining plays a crucial role in delivering precision. But for many looking to use Usinage CNC, the burning question is: how much does CNC machining actually cost in the U.S.?

This article will delve into the key factors affecting Coûts d'usinage CNC, revealing the secrets behind the pricing, and providing practical advice to help you choose the right machining provider with the ideal cost-performance ratio.

CNC Machining Prices: A Multitude of Factors Influence Precise Estimation

CNC machining prices aren’t set in stone; they’re more like a kaleidoscope, shaped by various factors. Understanding these factors is key to accurately estimating costs.

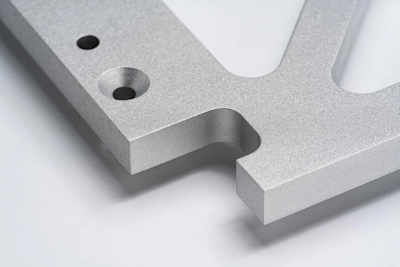

- Matériaux: The price of different materials can vary drastically. For instance, common and easy-to-machine aluminum alloys are relatively cheap, while high-strength, corrosion-resistant titanium alloys can be quite pricey. Additionally, factors like material thickness and surface treatment also impact costs.

- Complexity of Machining: The difficulty of the machining task dictates the time and labor required. Simple parts might be finished in minutes, while complex components could take hours or even days, causing prices to soar.

- Precision Requirements: Striving for high precision demands advanced equipment and meticulous processes, which naturally increases the price.

- Batch Size: Larger batch productions allow the cost per unit to be spread across more products, usually resulting in a lower price than small-batch runs.

- Location of the Machining Provider: Variations in labor costs, material prices, and taxes in different regions can significantly affect machining prices.

- Experience and Credentials of the Provider: Experienced machinists often deliver higher-quality service, but their prices can be steeper.

Études de cas :

- Simple Aluminum Parts: Machining costs may range from a few dollars to several tens of dollars, ideal for batch production or basic prototypes.

- Complex Stainless Steel Components: Costs can vary from several tens to a few hundred dollars, suited for parts requiring high strength and corrosion resistance.

- High-Precision Titanium Parts: Expect machining costs to range from a few hundred to several thousand dollars, perfect for aerospace, medical, or other precision-demanding fields.

How to Find More Cost-Effective CNC Machining Providers?

- Utilize Online Quoting Platforms: Many platforms allow you to quickly obtain quotes from multiple providers, making price and service comparison a breeze.

- Consult Multiple Providers: Don’t settle for just one provider; reach out to as many as possible to compare prices and services, ensuring you find the best fit.

- Check Credentials and Reputation: Review providers’ websites, customer reviews, and industry certifications to ensure their reliability and qualifications.

- Explore Providers’ Past Projects: Ask about previous projects to gauge their experience and capability, helping you determine if they meet your needs.

DIY CNC Machining: A Different Path, but Choose Wisely

For simpler machining projects, you might consider purchasing CNC equipment for DIY machining. However, be cautious—DIY machining requires a certain level of expertise and skills, along with an investment in equipment and materials. Make sure to assess your situation carefully before diving in.

The knowledge about CNC machining you should know:https://en.wikipedia.org/wiki/Multiaxis_machining

Conclusion :

CNC machining prices are far from a straightforward number; they are influenced by various factors and require a comprehensive evaluation based on your specific situation. We hope this article provides you with a thorough pricing guide, helping you better understand the cost structure of CNC machining and find a more cost-effective solution, ultimately achieving your machining goals.