Aluminum CNC machining parts have become essential across industries, from aerospace and automotive to consumer electronics and medical devices. The precision, strength-to-weight ratio, and versatility of aluminum make it an ideal material for CNC machining, offering manufacturers endless possibilities for creating high-performance components. But why exactly are aluminum CNC machining parts so popular, and what makes them stand out compared to other materials? Let’s dive deep into the world of aluminum CNC machining to explore its benefits, applications, and everything in between.

What Are Aluminum CNC Machining Parts?

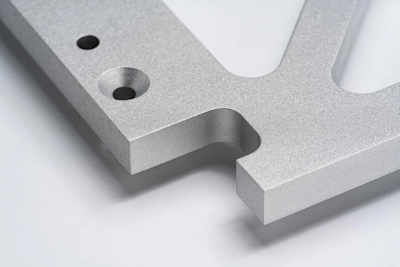

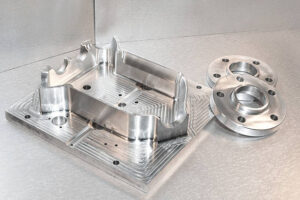

Aluminum CNC machining parts are components manufactured from aluminum using Computer Numerical Control (CNC) machining. CNC machining is a subtractive manufacturing process where a machine controlled by a computer program removes material from a solid aluminum block (or billet) to create complex and precise parts. This method offers high accuracy and repeatability, making it suitable for both prototyping and large-scale production.

There are various types of aluminum alloys used in CNC machining, such as 6061, 7075, and 2024, each offering specific mechanical properties suited for different applications. Aluminum’s unique characteristics, such as corrosion resistance, thermal conductivity, and lightweight, make it an attractive option for many industries.

Why Choose Aluminum for CNC Machining?

Aluminum offers several advantages over other metals like steel or titanium in CNC machining processes. Here are some of the reasons why aluminum CNC machining parts are preferred:

- Lightweight and Strong: Aluminum is known for its excellent strength-to-weight ratio, which is crucial in industries where reducing weight is important, such as automotive and aerospace. Despite being lightweight, aluminum alloys can exhibit high tensile strength, especially when heat-treated.

- Résistance à la corrosion: Most aluminum alloys offer natural corrosion resistance due to the formation of an oxide layer when exposed to air. This makes aluminum suitable for applications exposed to harsh environments, including marine and outdoor use.

- Good Thermal and Electrical Conductivity: Aluminum is an excellent conductor of heat and electricity, making it ideal for electronic components, heat sinks, and thermal management systems.

- Cost-Effective: Aluminum is more affordable than many other metals, such as titanium. This, combined with its machinability, makes it a cost-effective material for manufacturing parts, especially when large quantities are required.

- Recyclability: Aluminum is 100% recyclable without loss of properties, making it a sustainable choice for eco-conscious manufacturers. Recycling aluminum also uses less energy compared to producing new aluminum from raw materials.

- Machinability: Aluminum is relatively soft and easy to machine compared to harder metals like stainless steel or titanium. It allows for faster machining speeds and lower tool wear, which translates into reduced production costs and faster turnaround times.

Common Aluminum Alloys for CNC Machining

Different aluminum alloys have distinct properties, so selecting the right one for CNC machining is crucial depending on the specific application. Here are some of the most commonly used aluminum alloys:

- Aluminum 6061: One of the most versatile and commonly used aluminum alloys, 6061 offers good mechanical properties, corrosion resistance, and ease of machining. It is ideal for applications in structural components, frames, and automotive parts.

- Aluminum 7075: Known for its exceptional strength, 7075 is often used in aerospace and defense applications. While it is more expensive and harder to machine than 6061, its superior strength makes it ideal for critical components subjected to high stress.

- Aluminum 2024: This alloy is known for its high strength and fatigue resistance, making it suitable for aerospace applications where durability and reliability are key.

- Aluminum 5052: With excellent corrosion resistance, 5052 is often used in marine environments and other applications where exposure to moisture or salt is a concern.

- Aluminum 6082: Similar to 6061, this alloy offers good strength and machinability but is more commonly used in Europe. It is often found in structural applications and bridge construction.

Each alloy has its strengths and weaknesses, and selecting the right one depends on factors like the environment, mechanical requirements, and cost.

Key Applications of Aluminum CNC Machining Parts

Aluminum CNC machining parts are integral to many industries. Here are some of the major applications:

- Aérospatiale: Weight reduction is critical in the aerospace industry, where every gram saved can result in better fuel efficiency and performance. Aluminum’s light weight and high strength make it the perfect material for aircraft components like fuselages, wings, and landing gear parts. Aluminum CNC machining also ensures tight tolerances and complex geometries, which are vital in this sector.

- Automobile: In automotive manufacturing, aluminum CNC machining parts are used for engine components, brackets, frames, and suspension parts. The lightweight nature of aluminum helps improve vehicle performance, fuel efficiency, and handling.

- Dispositifs médicaux: The medical field requires highly precise and reliable components, and aluminum CNC machining offers the precision necessary for instruments, surgical devices, and even prosthetic components. Its biocompatibility and corrosion resistance make it a suitable material for medical applications.

- Électronique: Aluminum is widely used in the production of electronic devices due to its excellent thermal and electrical conductivity. It’s often machined into heat sinks, enclosures, and housings for circuit boards and other sensitive components.

- Biens de consommation: From smartphone cases to sporting equipment, aluminum CNC machining is used in various consumer products. Its aesthetic appeal, combined with its strength and durability, makes it an attractive material for high-end consumer goods.

- Robotics and Automation: As industries move towards automation, aluminum CNC machined parts are increasingly used in robotic arms, frames, and other components where precision, strength, and weight are essential.

- Marine Industry: Thanks to its corrosion resistance, aluminum is frequently used in marine applications, including boat hulls, ship components, and offshore equipment. CNC machining allows for the creation of intricate parts that can withstand the harsh marine environment.

The CNC Machining Process for Aluminum

Now that we’ve covered the benefits and applications of aluminum CNC machining parts, let’s take a closer look at the CNC machining process itself.

- Conception et modélisation CAO: The first step in CNC machining is creating a computer-aided design (CAD) model of the part to be produced. This digital model is essential for determining the part’s dimensions, geometry, and features. Modern CAD software allows designers to create highly detailed 3D models, ensuring that the final product meets all specifications.

- CAM Programming: Once the CAD model is ready, it is converted into a CNC program using computer-aided manufacturing (CAM) software. This program contains instructions for the CNC machine, including the tool paths, cutting speeds, and feed rates required to machine the part from an aluminum billet.

- Material Selection and Setup: Aluminum billets or bars are selected based on the alloy type and the size required for the part. The material is then secured onto the CNC machine’s worktable or chuck, ensuring it remains stable during machining.

- CNC Machining Operations: The CNC machine then performs various machining operations such as milling, turning, drilling, and tapping to shape the aluminum billet into the desired part. CNC machines use cutting tools like end mills and drills to remove material and create precise features such as holes, threads, and complex geometries.

- Quality Inspection and Finishing: Once the part is machined, it undergoes a thorough quality inspection using tools like coordinate measuring machines (CMMs) to ensure it meets the required tolerances and specifications. Depending on the application, additional finishing processes like anodizing, powder coating, or polishing may be applied to enhance the part’s surface appearance and durability.

- Assembly and Delivery: If the aluminum part is part of a larger assembly, it may be integrated with other components before being delivered to the customer.

what is aluminum Multi-Axis Machining https://en.wikipedia.org/wiki/Multiaxis_machining

Surface Finishing for Aluminum CNC Machining Parts

Surface finishing is an essential aspect of aluminum CNC machining. Different finishes can improve the part’s appearance, corrosion resistance, and functionality. Some common surface finishing options include:

- Anodisation: Anodizing is a popular surface treatment for aluminum CNC machined parts. It enhances corrosion resistance, improves wear resistance, and can add a decorative finish in a variety of colors. The anodizing process involves creating an oxide layer on the aluminum part’s surface, which increases its durability and hardness.

- Revêtement par poudre: Powder coating involves applying a dry powder to the part, which is then cured under heat to form a tough, protective layer. This finish is highly durable, resistant to wear, and available in various colors.

- Polissage: Polishing is a finishing process that smooths the surface of aluminum parts to create a shiny, reflective appearance. It’s commonly used for aesthetic purposes in consumer goods and automotive parts.

- Bead Blasting: Bead blasting involves propelling fine glass or ceramic beads at high pressure onto the aluminum part’s surface. This process removes surface imperfections and creates a uniform matte finish.

- Brossage: Brushed aluminum finishes are created by polishing the surface with a fine abrasive to create a textured, linear pattern. This finish is often used for aesthetic purposes, especially in consumer electronics.

The knowledge about finition de surface

Challenges in Aluminum CNC Machining

Despite its many advantages, aluminum CNC machining does come with some challenges. Understanding these issues is key to producing high-quality parts consistently.

- Chip Formation: Aluminum tends to form long chips during machining, which can clog the machine and damage tools. Using proper cutting tools and coolant strategies helps manage chip formation and evacuation.

- Thermal Expansion: Aluminum has a higher thermal expansion rate than other metals like steel. During CNC machining, heat generated by cutting tools can cause the material to expand, affecting the part’s dimensions. Machinists must account for this and use proper cooling techniques to maintain accuracy.

- Surface Finish Quality: Achieving a perfect surface finish on aluminum can be challenging, especially when machining intricate geometries. Proper tooling, cutting speeds, and finishing processes are essential to ensuring a smooth and consistent finish.

- Tool Wear: While aluminum is softer than steel, it can still cause significant tool wear, especially when machining harder aluminum alloys like 7075. Carbide cutting tools are commonly used to extend tool life when machining aluminum.

CNC Machining Trends and the Future of Aluminum Parts

As technology evolves, CNC machining is becoming even more sophisticated, and aluminum parts are playing a central role in innovation. Some of the key trends shaping the future of CNC machining include:

- Automation and Industry 4.0: With the rise of automation and smart manufacturing, CNC machining processes are becoming more autonomous. Robots are increasingly being used to load and unload materials, while advanced software integrates with CNC machines to optimize cutting strategies and reduce downtime.

- Additive Manufacturing Integration: While CNC machining is primarily a subtractive process, many manufacturers are exploring hybrid approaches that combine additive manufacturing (3D printing) with CNC machining. This allows for more complex part geometries and optimized material use.

- Advanced Materials: Aluminum alloys continue to evolve, with new materials offering improved strength, heat resistance, and corrosion resistance. These advancements will open up new possibilities for aluminum CNC machined parts in industries like aerospace, defense, and automotive.

- Sustainability: With increasing pressure to reduce waste and lower carbon footprints, manufacturers are focusing on making CNC machining more sustainable. Recycling aluminum scrap, using eco-friendly coolants, and optimizing machining processes to minimize material waste are all part of this trend.