This article will dive deep into the world of 5 axis CNC machining services, explaining the technology, its wide range of applications, the level of precision it offers, and its future potential in manufacturing.

What Is 5 Axis CNC Machining?

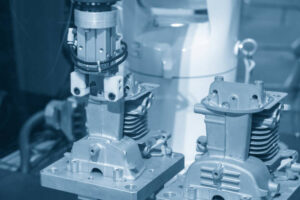

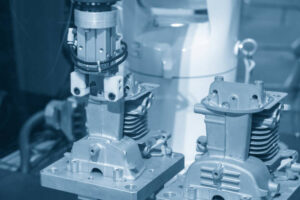

Before we explore the benefits and applications of 5 axis CNC machining services, it’s important to understand how it works. The term “5 axis” refers to the number of directions the cutting tool can move simultaneously. In 3 axis machining, the cutting tool moves across the X, Y, and Z axes. However, with 5 axis machining, two additional axes are added—typically rotational axes (A, B, or C) around the X or Y planes. This allows for far greater flexibility in movement and more complex shapes.

Here’s how 5 axis CNC machining works:

- X Axis: Moves the tool left and right.

- Y Axis: Moves the tool forward and backward.

- Z Axis: Moves the tool up and down.

- A Axis: Rotates around the X axis.

- B Axis: Rotates around the Y axis.

With these five axes working together, manufacturers can create complex geometries in a single setup, reducing production time and increasing efficiency.

Benefits of 5 Axis CNC Machining Services

The ability to machine parts from multiple angles without manual intervention makes 5 axis Services d'usinage CNC the preferred choice for intricate and highly precise components. Here are the key benefits:

- Greater Precision: By machining parts from different angles in a single setup, 5 axis machining eliminates the need for multiple fixtures. This reduces the risk of human error and ensures higher precision, which is especially important in industries that demand tight tolerances, like aerospace and medical device manufacturing.

- Enhanced Flexibility: The additional axes allow manufacturers to produce more complex and detailed parts that would be impossible or inefficient with 3 or 4 axis machines. This flexibility is critical in designing parts with undercuts, curved surfaces, and intricate shapes.

- Faster Production: Because 5 axis machines can cut on multiple planes simultaneously, they significantly reduce the number of setups required for each part. This leads to faster cycle times and, ultimately, reduced production costs.

- Improved Surface Finishes: With the tool approaching the part from different angles, 5 axis machining can achieve smoother surface finishes with less post-machining work required. This is particularly valuable for components that need a high-quality aesthetic finish.

- Reduced Tool Wear: The ability to approach the workpiece from multiple directions minimizes the strain on cutting tools, extending their lifespan and reducing the overall cost of consumables in the machining process.

Applications of 5 Axis CNC Machining Services

Thanks to its versatility and precision, 5 axis CNC machining services are used in a wide variety of industries. Let’s take a closer look at some of the key applications.

1. Aerospace Industry

The aerospace sector is perhaps one of the biggest beneficiaries of 5 axis CNC machining. Aircraft components often feature complex, curved surfaces that require exacting precision to ensure the aircraft’s performance and safety. Parts like turbine blades, engine components, and structural elements must meet strict tolerances, making 5 axis machining essential for the aerospace industry.

In addition, the lightweight materials used in aerospace, such as titanium and high-strength aluminum alloys, are difficult to machine with traditional methods. The flexibility of 5 axis machining allows for optimal cutting angles, reducing tool wear and improving the machining efficiency of these tough materials.

2. Automotive Industry

In the automotive world, innovation and precision are paramount. From performance cars to electric vehicles, manufacturers are constantly pushing the boundaries of what is possible. 5 axis CNC machining services enable the creation of intricate engine parts, gearboxes, and complex interior components that improve vehicle performance and safety.

Moreover, 5 axis machining allows for prototyping and production of lightweight components that enhance fuel efficiency without compromising strength, a key focus in the automotive industry as manufacturers work towards greener, more sustainable solutions.

3. Medical Devices

The medical field demands a high level of precision, as even the smallest errors can lead to significant risks. Whether producing surgical instruments, orthopedic implants, or dental devices, 5 axis CNC machining ensures the tight tolerances and surface finishes required for medical-grade components.

For example, complex joint replacements or bone plates can be manufactured using 5 axis technology, allowing for detailed and customized shapes that fit each patient’s anatomy. Additionally, biocompatible materials like titanium and stainless steel are commonly used in these applications, and 5 axis machining makes it easier to work with these challenging materials.

4. Robotics and Automation

As the demand for automation increases, so does the need for precise robotic components. Robotic arms, joints, and gear mechanisms must all be produced with extreme accuracy to ensure smooth and reliable operation. 5 axis CNC machining services make it possible to create the intricate, multi-faceted components required for modern robots.

In addition, as robots become more complex, the need for lightweight and durable materials becomes crucial. 5 axis machining can easily handle advanced materials like aluminum, titanium, and composites, producing parts that contribute to the robot’s overall efficiency.

5. Energy Sector

The energy industry, particularly in the oil and gas and renewable energy sectors, relies heavily on complex parts for turbines, pumps, and engines. These components often require tight tolerances and need to withstand high pressures and extreme environments. 5 axis CNC machining services provide the accuracy and efficiency necessary to produce these critical components.

Moreover, the growing renewable energy sector, including wind turbines and solar power systems, also benefits from the precision and versatility offered by 5 axis machining. Components such as turbine blades and precision gears are essential for optimizing energy production.

Precision in 5 Axis CNC Machining

Precision is at the heart of 5 axis CNC machining services, making it the go-to technology for industries that require flawless accuracy. But what makes 5 axis machining so precise?

- Single Setup Machining: One of the primary reasons for the high precision of 5 axis CNC machining is its ability to machine parts in a single setup. Traditional 3 axis machines often require multiple setups to machine different sides of a part, increasing the risk of error during repositioning. With 5 axis machining, parts are machined from multiple angles without being removed from the workholding, ensuring consistent accuracy throughout the entire process.

- Tight Tolerances: In industries like aerospace, medical, and defense, tolerances of ±0.001 inches (or even tighter) are often required. 5 axis machines are capable of meeting these exacting standards, ensuring that each part is produced to the required specifications.

- Advanced CNC Controls: Modern 5 axis CNC machines are equipped with sophisticated software that enables real-time adjustments to cutting paths, speeds, and tool angles. This ensures that the machining process remains accurate even when dealing with complex geometries or difficult-to-machine materials.

- Reduced Tool Vibration: Tool vibration is one of the leading causes of inaccuracies in machining. 5 axis machines allow for shorter cutting tools and more optimized cutting angles, reducing tool vibration and increasing precision.

- Multi-Directional Machining: Because the tool can approach the workpiece from multiple directions, 5 axis machining ensures that even the most complex geometries are machined with precision. This is particularly important for parts with undercuts, angled surfaces, or intricate details that would be impossible to machine using a 3 axis machine.

The Future of 5 Axis CNC Machining Services

As industries continue to push for greater innovation, efficiency, and sustainability, 5 axis CNC machining services are set to play an even more significant role in the future of manufacturing. Here are some of the key trends that will shape the future of this technology:

1. Automation and Smart Manufacturing

With the rise of Industry 4.0 and smart manufacturing, CNC machining is becoming increasingly automated. Robots are now being used to load and unload workpieces, while advanced sensors and data analytics monitor the machining process in real-time. This level of automation reduces human error, increases productivity, and allows for more complex parts to be produced with less manual intervention.

In the future, we can expect 5 axis CNC machines to become even more integrated into fully automated production lines, where machines communicate with each other and make real-time adjustments based on data analysis.

2. Additive Manufacturing Integration

One of the most exciting developments in modern manufacturing is the integration of additive manufacturing (3D printing) with CNC machining. By combining these two technologies, manufacturers can produce highly complex parts that were previously impossible to machine.

For example, a part could be 3D printed to near-net shape and then finished with 5 axis CNC machining to achieve the desired tolerances and surface finishes. This hybrid approach is already being used in aerospace, automotive, and medical industries and is likely to become more widespread in the coming years.

3. Advanced Materials

As materials science advances, new alloys and composites are being developed that offer superior strength,

heat resistance, and durability compared to traditional materials. These advanced materials, such as high-performance aluminum alloys, titanium, and carbon composites, present new challenges for machining. However, 5 axis CNC machining services are well-positioned to meet these challenges.

In particular, industries like aerospace, defense, and automotive are increasingly relying on these materials for components that need to withstand extreme conditions. The ability of 5 axis machines to approach workpieces from multiple angles allows for optimal cutting strategies, reducing tool wear and improving precision when working with tough, advanced materials.

4. Customization and On-Demand Manufacturing

As customer demands for personalized and customized products increase, manufacturers are turning to 5 axis CNC machining for rapid prototyping and on-demand production. With the flexibility of 5 axis machining, manufacturers can quickly produce small batches of customized parts without the need for expensive tooling or long lead times.

This trend is particularly evident in the medical device and automotive sectors, where customized implants and car components are increasingly in demand. In the future, we can expect to see 5 axis CNC machining services playing an even more prominent role in enabling mass customization and reducing production times for individualized parts.

5. Sustainability and Efficiency

As environmental concerns grow, there is increasing pressure on manufacturers to reduce waste and lower their carbon footprints. 5 axis CNC machining services can contribute to these goals by optimizing material usage, reducing the need for multiple setups, and minimizing machining time. Additionally, the ability to machine parts from multiple angles without repositioning reduces scrap material and increases overall efficiency.

Another sustainability trend in CNC machining is the use of eco-friendly coolants and lubricants. Traditional coolants can be harmful to the environment, but modern 5 axis machines are increasingly using alternative solutions that are safer and more sustainable.

Conclusion

In today’s rapidly evolving manufacturing landscape, 5 axis CNC machining services stand out as a critical technology for producing complex, high-precision components across a wide range of industries. From aerospace to medical devices, automotive to energy, the versatility and precision of 5 axis machining offer manufacturers the ability to create intricate parts with tight tolerances and excellent surface finishes.

The future of 5 axis CNC machining is bright, with innovations in automation, materials, and sustainable manufacturing poised to enhance its capabilities even further. As industries continue to push the boundaries of design and engineering, 5 axis CNC machining services will remain at the forefront of modern manufacturing, delivering the precision, efficiency, and flexibility needed to meet the challenges of the future.

Whether you’re looking for a reliable solution for producing complex aerospace components, medical devices, or automotive parts, 5 axis CNC machining services provide the precision and versatility required for the most demanding applications. By leveraging this advanced technology, manufacturers can not only meet today’s manufacturing challenges but also prepare for the innovations of tomorrow.

This comprehensive exploration of 5 axis CNC machining services demonstrates its key role in modern manufacturing, providing insights into its applications, precision, and future development. As this technology continues to evolve, it will undoubtedly lead to even more advancements, making it an indispensable tool in industries where precision and efficiency are paramount.

By focusing on the specific benefits, applications, and future trends, this article presents a humanized yet technical overview of 5 axis CNC machining services, helping readers understand why this technology is so vital in today’s manufacturing world.

Références: