Introducción: El viaje de los componentes de automoción desde las materias primas hasta las manos del consumidor final es un proceso complejo e intrincado. A lo largo de este viaje, la tecnología de control numérico por ordenador (CNC) desempeña un papel crucial. Este artículo explora la aplicación de CNC application in every aspect of the process, including raw material selection and processing, the refinement of CNC applications, standardized quality inspection processes, and personalized customization in the retail segment.

Raw Material Selection and Processing

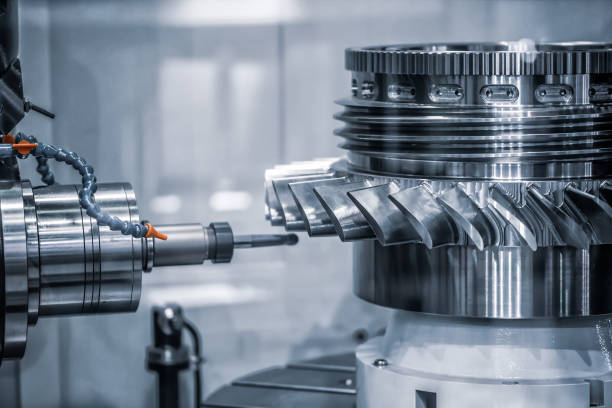

Automotive components are typically made from metals, plastics, and other materials that require precise CNC machining to meet their dimensional, shape, and performance specifications. CNC technology enables high-precision processing, ensuring the interchangeability and assembly quality of the components. The high precision and stability of CNC technology are key factors in this process.

- (1) Raw Material Selection: CNC technology allows for the selection of appropriate materials based on the performance requirements of the components. For example, components that withstand high pressure and temperature can be made from materials that are resistant to heat and pressure. Components that experience significant impact and wear require materials with high hardness and durability. CNC technology can accurately machine these materials to meet the required specifications.

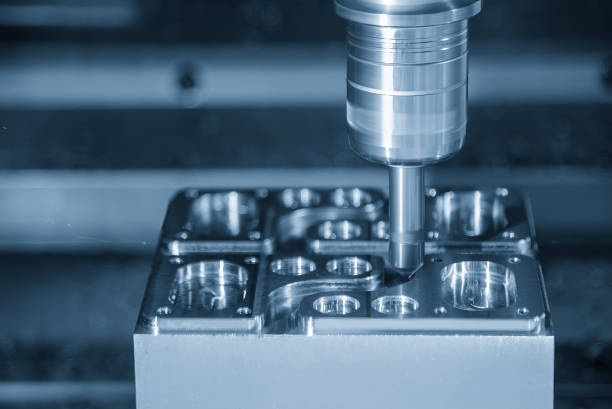

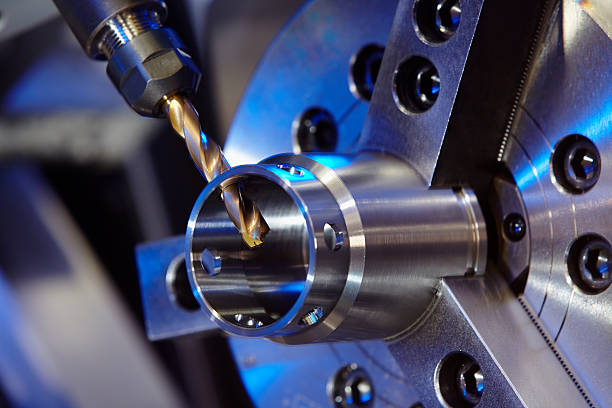

- (2) Precision Machining: CNC technology can achieve micro-level precision in the machining process, enabling components to have dimensions and shapes with an exceptional level of precision. For instance, in the machining of automotive engine cylinder heads, multiple fuel injection holes need to be accurately drilled to ensure precise fuel injection and combustion. CNC technology can accurately create these holes, enhancing engine performance and fuel efficiency.

The Refinement of CNC Applications

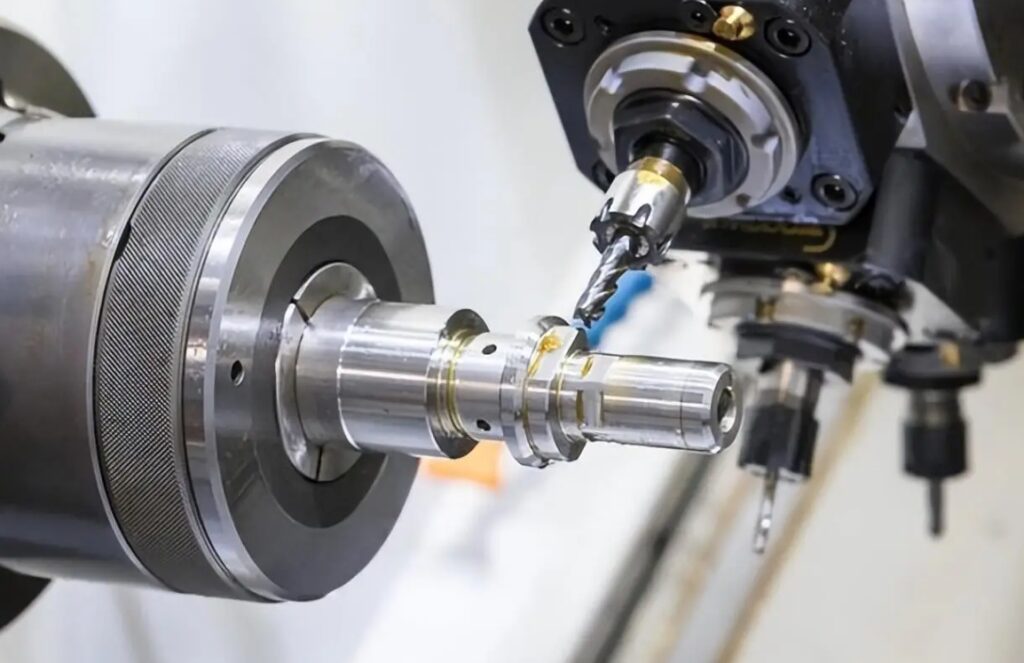

- (1) Complex Shape Machining: CNC technology enables the creation of complex shapes and structures that are difficult to achieve with traditional manual operations. For example, the exterior design of automobiles often requires components to have intricate curves and shapes, which can be precisely machined using CNC technology through computer programming.

- (2) Efficiency in Mass Production: CNC technology has significant advantages in mass production. Computer programming allows for the automated machining of multiple components, increasing production efficiency and reducing costs.

Standardized Quality Inspection Processes

- (1) Automated Inspection: CNC technology facilitates the precise measurement and inspection of automotive components, ensuring that they meet quality standards. Computer programming enables the automation of inspection processes, enhancing efficiency and accuracy.

- (2) Comprehensive Inspection: Using CNC technology, such as three-dimensional coordinate measuring machines, components can be accurately measured and inspected for dimensional accuracy and shape. Thorough inspections ensure that components meet design requirements and standards, thereby guaranteeing the overall performance and safety of the vehicle.

Personalized Customization in the Retail Segment

- (1) Customized Production: With the continuous advancement of CNC technology, automotive component production is increasingly trending towards customization and personalization. CNC technology allows for the personalized machining of components to meet consumer demands for uniqueness and individualization. For instance, consumers can customize specific dimensions, shapes, and colors to suit their needs.

- (2) Increased Added Value: Personalized customization not only meets consumer demands for individuality .but also enhances the added value and market competitiveness of components. Manufacturers can offer uniquely designed and performing components through CNC technology, attracting the attention and purchases of consumers.

Throughout the journey from raw materials to the hands of the consumer, CNC technology plays a vital role in every aspect.

Whether it is precise machining, refined quality inspection, or personalized retail offerings, CNC technology is driving the development of the automotive manufacturing industry.

As CNC technology continues to evolve, we can anticipate that the automotive industry will enter an era of increased refinement and personalization.