Introduction:

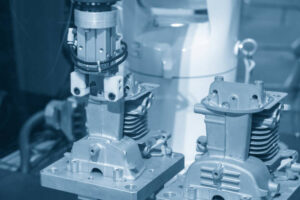

Do you have an exciting product idea but struggle to find a reliable prototyping solution? Are you looking for a fast and precise way to transform your designs into reality? CNC prototyping is your answer!

GCH PROCESS, a leader in sustainable prototyping, has become the go-to partner for entrepreneurs and businesses through our high precision, flexibility, and rapid turnaround times. We help you validate designs, test functionality, gather customer feedback, and launch your products to market efficiently.

Why Choose GCH PROCESS for Your Prototyping Needs?

Our CNC prototyping process offers numerous advantages:

Rapid Prototyping: Our advanced equipment and experienced team deliver quick results for time-sensitive projects.

High-Precision Manufacturing: Our CNC machines achieve micron-level accuracy, ensuring perfect alignment with design specifications.

Complex Geometries: We excel at handling intricate shapes and complex prototyping designs.

Diverse Prototyping Materials: We work with:

- Metals (aluminum, steel, copper)

- Plastics (ABS, PC, PA)

- Wood and composites

Customized Solutions: We tailor our prototyping process to meet your unique specifications.

Our Comprehensive Prototyping Services:

We offer end-to-end solutions covering design, machining, and surface finishing:

Material Selection: Wide range of prototyping materials to choose from

Manufacturing Processes: Milling, turning, drilling, wire-cutting, water-jet cutting

Surface Treatments: Sandblasting, plating, anodizing, painting

Precision & Dimensioning: Various accuracy levels to match your requirements

Quick Delivery: Fast turnaround times for urgent projects

No Minimum Order: Single-unit prototypes welcome

The GCH PROCESS Advantage:

Cost-Effective: Our prototyping cost calculator helps you optimize your budget while maintaining quality.

Rapid Iteration: Quick design validation and improvement cycles.

Quality Assurance: High-precision manufacturing ensures perfect prototype-to-design matching.

Starting Your Project with GCH PROCESS:

Simply provide your:

- 3D models or engineering drawings

- Material preferences

- Dimensional requirements

- Surface finish specifications

Our team will provide a free quote for your sustainable prototyping project.

Success Stories:

Case Study 1: Smart Home Product – Smart Door Lock Prototype

Client Need: A smart home company required a prototype for an innovative smart door lock integrating fingerprint recognition, facial recognition, and Bluetooth unlocking capabilities, all wrapped in a minimalist design.

GCH PROCESS Solution:

Material Selection: Premium zinc alloy was chosen for durability and aesthetic appeal.

Prototyping Process: Utilized precision CNC machining to craft the lock housing and create precise mounting positions for biometric modules.

Surface Treatment: Applied electroplating for enhanced aesthetics and corrosion resistance.

Outcome: Through our sustainable prototyping approach, GCH PROCESS successfully delivered a fully functional smart lock prototype that enabled the client to complete product testing and validation, establishing a solid foundation for mass production.

Case Study 2: Medical Device – High-Precision Surgical Instrument Prototype

Client Need: A medical device manufacturer required a prototype for a novel surgical instrument demanding high precision, durability, and ergonomic operation for specific surgical procedures.

GCH PROCESS Solution:

Prototyping Materials: Medical-grade stainless steel was selected for its corrosion resistance, antibacterial properties, and biocompatibility.

Prototyping Design: Employed high-precision CNC machining to achieve exact dimensional accuracy, superior surface finish, and complex geometrical features.

Surface Treatment: Implemented specialized surface treatment techniques to enhance wear resistance and longevity.

Outcome: Our on-demand prototyping services delivered a surgical instrument prototype meeting all specifications, combining functionality with superior ergonomics and aesthetics, facilitating the client’s R&D and product promotion efforts.

Case Study 3: Industrial Design – Customized Product Prototype

Client Need: A designer sought to create a prototype for a customized car model that would capture intricate automotive details while incorporating unique personalized elements.

GCH PROCESS Solution:

Material Selection: Used a combination of high-grade materials to achieve the desired detail and finish.

Prototyping Process: Implemented advanced CNC machining techniques to reproduce complex automotive details and custom features.

Surface Treatment: Applied professional finishing techniques to achieve a showroom-quality appearance.

Outcome: Through our comprehensive prototyping design process, we delivered a highly detailed, customized car model prototype that perfectly balanced authenticity with personalized design elements, exceeding the client’s expectations.

Each case study demonstrates our commitment to excellence in prototyping, showcasing our ability to handle diverse projects while maintaining high standards of quality and precision. Our success in these projects highlights how our prototyping cost calculator helps clients achieve optimal results within their budget constraints.

Conclusión:

GCH PROCESS delivers fast, precise, and affordable on-demand prototyping solutions to bring your product ideas to life. Choose us as your trusted partner in turning your product dreams into reality!

Want to learn more about our prototyping process or get a quick quote? Contact our team today to discuss your project needs and explore how our prototyping solutions can benefit your business.

References: https://en.wikipedia.org/wiki/Prototype