Hey there, manufacturing enthusiasts!Ready to dive into the mind-blowing world of CNC precision machining? Buckle up, because we’re about to take a wild ride from computer screens to factory floors. As someone who’s been elbow-deep in machine oil for years, trust me when I say – this is where the real magic happens!

CNC Precision Machining: The Game-Changer in Modern Manufacturing

Imagine having a super-smart robot that can create almost anything you design, with precision that would make a brain surgeon jealous. That’s CNC (Computer Numerical Control) precision machining in a nutshell. It’s like giving a computer the keys to a high-tech workshop. The result? Parts so precise, they’ll make your head spin!

The Dream Team of CNC Precision Machining

Máquinas CNC

These bad boys are the muscle. They take digital designs and turn them into real-world objects with mind-blowing accuracy.

CAM Software

Think of this as the brains of the operation. It translates your brilliant designs into a language the machines understand. It’s like a universal translator for the manufacturing world!

NC Code

This is the secret sauce – the actual instructions that tell the machine exactly what to do. It’s like a detailed recipe for creating perfect parts every single time.

From Pixels to Parts: The CNC Journey

Design Phase

Everything starts with a great idea and some fancy computer work. This is where engineers get to play digital Lego, creating virtual versions of the parts we need.

CAM Magic

Next, we feed our designs into CAM software. This is where the real wizardry happens, turning our digital dreams into step-by-step instructions for the machines.

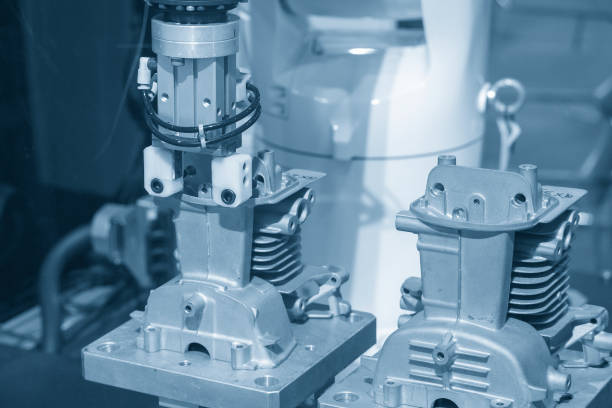

Machining Madness

Now the fun really begins! The CNC machine springs to life, whirring and spinning as it carves, cuts, and shapes raw materials into finished parts. It’s like watching a sculptor work, only faster and with laser precision.

Quality Check

We don’t just make parts; we make perfect parts. Every piece gets checked and double-checked to make sure it’s up to snuff. Our machines are so smart, they even check themselves as they work!

Why CNC Precision Machining is the Bee’s Knees

Accuracy that’ll blow your socks off

We’re talking precision down to the width of a human hair. NASA would be jealous!

Consistency is key

Once we nail the programming, we can make thousands of identical parts. It’s like cloning, but for manufacturing.

Speed demon

These machines work faster than a caffeinated squirrel, cranking out parts at a pace that’ll make your head spin.

Jack of all trades

Need to switch from making car parts to medical devices? No problem! Just a bit of reprogramming, and we’re good to go.

Where You’ll Find CNC Precision Machining

This tech is everywhere, folks:

Aeroespacial

Keeping planes in the air with parts that are precise to the nth degree.

Medical field

Creating tools and implants that are changing lives, one precision cut at a time.

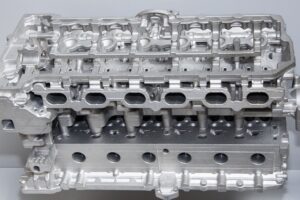

Automotive world

Making cars faster, safer, and more efficient with parts that fit like a glove.

Consumer goods

From the latest smartphone to the toys in your kid’s room – CNC’s got its fingerprints all over them.

Embracing Innovation: Always Moving Forward

The manufacturing world never stands still. As engineers, we’re always looking for ways to boost efficiency and cut costs. CNC machining technology is our trusty sidekick, constantly pushing boundaries and opening up new possibilities.

Take 5-axis CNC machining, for example.

It’s a real game-changer, allowing us to produce more accurate and complex parts while maintaining high standards.

Even cooler?

We’re adding smart tech to CNC systems. This not only ramps up production efficiency but also provides valuable data for continuous improvement. It’s like giving our machines a super-brain!

Wrapping It Up

CNC precision machining isn’t just about making stuff – it’s about pushing the boundaries of what’s possible in manufacturing. It’s the perfect blend of high-tech wizardry and good old-fashioned craftsmanship. Whether you’re an engineer, a curious student, or just someone who loves to know how things are made, understanding CNC precision machining gives you a peek behind the curtain of modern manufacturing.

Now, let me tell you about a company that’s really nailing this CNC precision machining game – GCH Process

These folks aren’t just another run-of-the-mill machine shop. They’re the real deal, holding an IATF:16949 certification, which is like the Oscar of the automotive quality management world. But here’s the kicker – they’re not just users of CNC technology; they’re a source CNC factory. That means they’re at the forefront of innovation, creating the very machines and processes that drive this industry forward.

What sets GCH Process apart

What sets GCH Process apart is their deep understanding of the entire CNC precision machining process. From design to final product, they’ve got it covered. Need a one-off prototype that pushes the limits of precision? They’re on it. Looking for high-volume production that doesn’t sacrifice quality? GCH Process has got you covered. They’re not just keeping up with the industry; they’re helping to define its future.

So, whether you’re in the market for CNC precision machining services or just fascinated by the tech (like me!)

Remember that companies like GCH Process are out there, turning digital dreams into tangible realities. They’re proof that with the right expertise and cutting-edge technology, the sky’s the limit in modern manufacturing.

And there you have it, folks – your ticket to the exciting world of CNC precision machining

Next time you pick up a precisely engineered product, you’ll know just how much awesome technology went into making it. Keep innovating, and keep machining!