China se ha convertido en líder mundial del mecanizado CNC, ofreciendo una combinación única de rentabilidad, mano de obra cualificada y capacidades de fabricación avanzadas. Este artículo se adentra en el intrincado mundo del Mecanizado CNC en ChinaEn esta sección se analizan sus puntos fuertes, sus retos y sus perspectivas de futuro.

Un centro de excelencia manufacturera:

El ascenso de China como potencia manufacturera se ha visto impulsado por su compromiso de Mecanizado CNC. Desde componentes intrincados para la electrónica hasta piezas complejas para las industrias automovilística y aeroespacial, los fabricantes chinos atienden una amplia gama de necesidades. Este crecimiento está impulsado por varios factores clave:

1. Soluciones rentables:

Menores costes laborales: Los competitivos costes de mano de obra de China ofrecen importantes ventajas de costes en comparación con muchos países desarrollados, lo que la convierte en una opción convincente para las empresas que buscan soluciones de mecanizado CNC asequibles.

Competitividad de precios: El panorama altamente competitivo del sector manufacturero chino hace bajar aún más los precios, lo que permite a las empresas adquirir piezas mecanizadas CNC de alta calidad a precios atractivos.

2. Mano de obra cualificada y experiencia:

Gran reserva de talento: China cuenta con una amplia mano de obra altamente cualificada en el sector manufacturero, con un gran número de profesionales del mecanizado CNC. Esta reserva de talento fácilmente disponible permite a las empresas acceder a maquinistas cualificados para diversos proyectos.

Experiencia en diversos sectores: Los fabricantes chinos han acumulado experiencia en diversas industrias, desde la automoción y la aeroespacial hasta la electrónica y los dispositivos médicos. Esta amplia experiencia les permite gestionar con destreza diversos proyectos de mecanizado CNC.

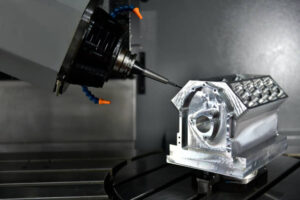

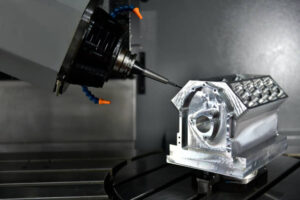

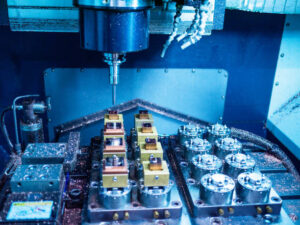

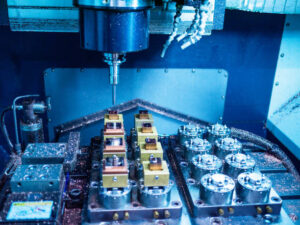

3. Capacidades de fabricación avanzada:

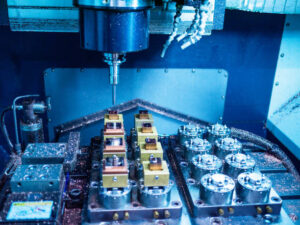

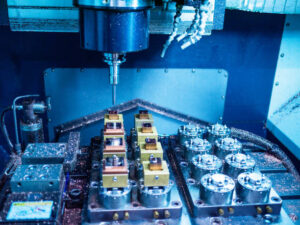

Inversión en equipos modernos: Los fabricantes chinos han realizado grandes inversiones en modernos equipos de mecanizado CNC, incluidas avanzadas máquinas multieje, centros de mecanizado de alta velocidad y sistemas automatizados. Esto garantiza una alta precisión, eficiencia y repetibilidad en la producción.

Amplia gama de materiales: Son expertos en trabajar con una gran variedad de materiales, incluidos metales (acero, aluminio, titanio), plásticos y materiales compuestos, cumpliendo diversos requisitos de los proyectos.

Navegar por el paisaje: Consideraciones para el éxito

Aunque China ofrece numerosas ventajas para el mecanizado CNC, es crucial navegar por el panorama con cuidado para garantizar el éxito. He aquí algunas consideraciones clave:

1. Garantía y control de calidad:

Elegir fabricantes reputados: Es esencial investigar a fondo. Seleccione fabricantes con un historial demostrado de calidad, certificaciones y satisfacción del cliente.

Comunicación y especificaciones claras: La comunicación eficaz es primordial. Proporcione dibujos claros, especificaciones detalladas y tolerancias precisas para minimizar las interpretaciones erróneas y garantizar los resultados deseados.

Sistemas de inspección y control de calidad: Infórmese sobre los sistemas de control de calidad y los procedimientos de inspección del fabricante para verificar el cumplimiento de las normas internacionales.

2. Plazos de entrega:

Comprender la capacidad de producción: Evalúe la capacidad de producción y la carga de trabajo actual del fabricante para asegurarse de que puede cumplir los plazos de su proyecto.

Envío y logística: Tenga en cuenta los costes y plazos de transporte, sobre todo en los envíos internacionales. Considere la disponibilidad de proveedores logísticos fiables y el impacto de los posibles retrasos.

3. Protección de la propiedad intelectual:

Acuerdos de confidencialidad: Consiga acuerdos de confidencialidad para salvaguardar sus diseños y su propiedad intelectual durante el proceso de colaboración.

Disposiciones contractuales: Incluya cláusulas claras de protección de la propiedad intelectual en el contrato, en las que se describan las responsabilidades y los derechos de propiedad relacionados con los diseños y las invenciones.

4. Consideraciones culturales:

Estilos de comunicación: Tenga en cuenta las posibles diferencias culturales en cuanto a estilos de comunicación y prácticas empresariales.

Barreras lingüísticas: Tenga en cuenta las barreras lingüísticas y la necesidad de traductores o intérpretes profesionales cuando se comunique con fabricantes chinos.

El futuro del mecanizado CNC en China:

Avances tecnológicos: China no deja de invertir en tecnología punta, desde avanzadas Centros de mecanizado CNC a la robótica y los sistemas de automatización, impulsando mejoras de la eficiencia y la calidad.

Integración de la Industria 4.0: El país está adoptando los principios de la Industria 4.0, integrando tecnologías de fabricación inteligentes y plataformas digitales para mejorar la conectividad, el análisis de datos y la optimización de la producción.

Centro mundial de la cadena de suministro: La ubicación estratégica de China, su infraestructura de fabricación bien desarrollada y su sólida red de cadena de suministro consolidan su posición como centro mundial de operaciones de mecanizado CNC.

Conclusión:

El mecanizado CNC en China ofrece una potente combinación de rentabilidad, mano de obra cualificada y capacidades de fabricación avanzadas. Al abordar el proceso con una investigación cuidadosa, una comunicación clara y acuerdos contractuales sólidos, las empresas pueden aprovechar las ventajas de este mercado dinámico. A medida que China sigue avanzando tecnológicamente y adopta los principios de la Industria 4.0, su papel en el panorama mundial del mecanizado CNC está llamado a ser aún más prominente en los próximos años.