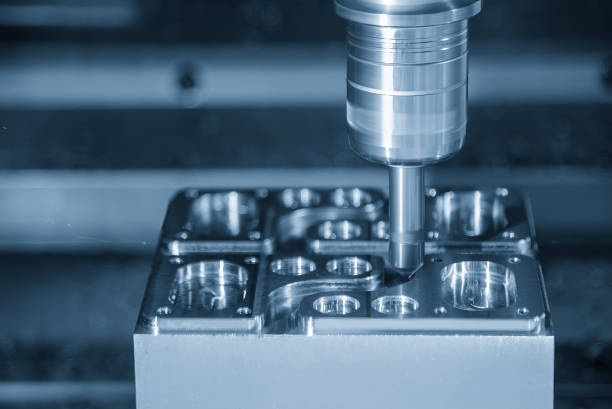

Tiene una gran idea para un nuevo producto, pero antes de poder darle vida, necesita fabricar esas piezas. Y si busca precisión y diseños complejos, el mecanizado CNC es probablemente su mejor opción.

But here’s the thing: CNC machining can feel like a black box. You know it’s cool, you know it’s precise, but you might be scratching your head about the cost.

Don’t worry! This guide is here to break down the factors that influence CNC machining service cost, help you figure out what’s fair, and give you tips for getting the best deal.

So, What Makes CNC Machining Cost More?

Think of it like ordering a custom pizza. You want extra toppings, a unique crust, and a special sauce? You’re gonna pay a bit more for that masterpiece! Same goes for Mecanizado CNC. Here’s what drives up the price:

1. The Fancy Ingredients: Material Matters

Aluminio: Think of this as your classic crust, pretty affordable and a good starting point.

Steel: A little more robust and strong, like adding some pepperoni.

Titanium: The luxury upgrade! It’s super strong and light, like adding truffles and gold flakes.

Plásticos: A great budget option if you don’t need serious strength.

Fibra de carbono: Whoa, this is like a gourmet pizza with exotic ingredients. Super light and super strong, but it comes with a price tag.

2. Design Complexity: The More Intricate, the More Costly

Simple Shapes: Easy peasy, like a plain cheese pizza.

Complex Shapes: Imagine a pizza with intricate designs, maybe a picture of a cat. More time and precision needed, meaning higher cost.

Tight Tolerances: Like getting your pizza cut into perfectly equal slices. More precision means more time and effort, so it’s pricier.

3. Part Size and Quantity: Bigger and More Is (Sometimes) Better

Size: Think of a giant pizza you can share with your whole crew. More material, more work, more cost.

Quantity: Ordering a bunch of pizzas for everyone in your office? You’ll probably get a discount per pizza. Same idea with CNC machining!

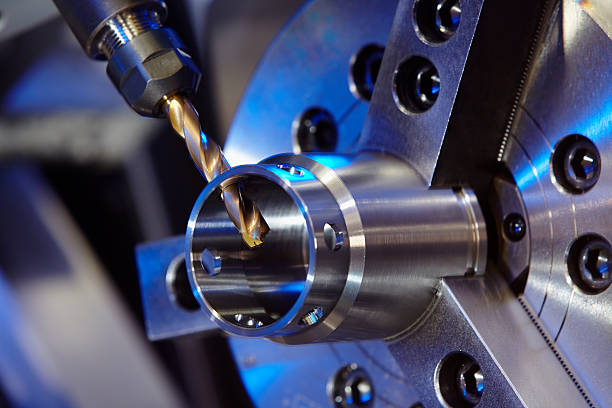

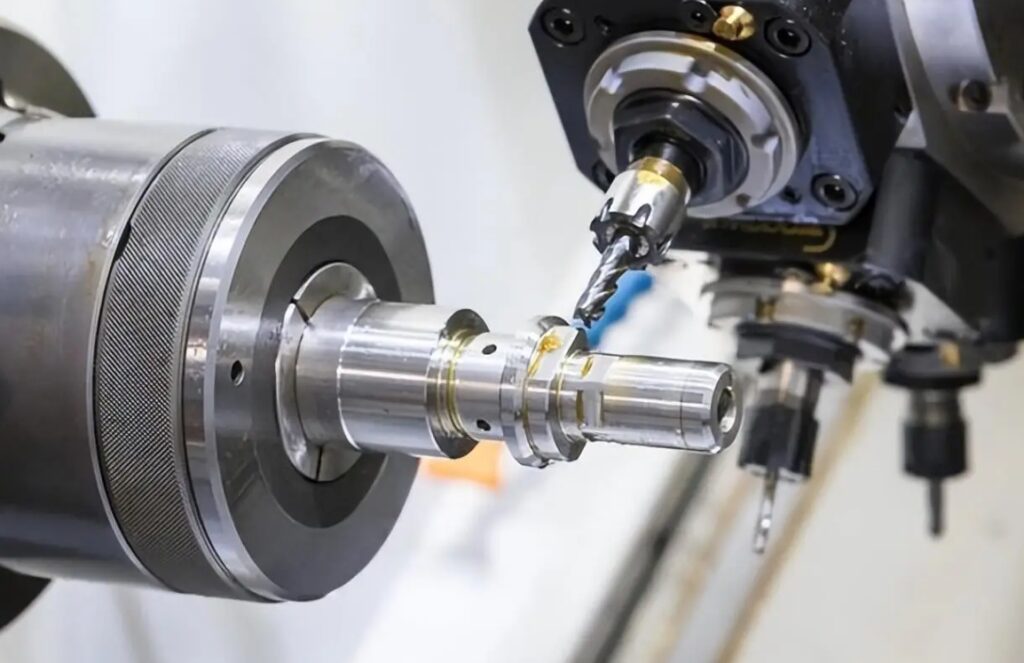

4. Machining Processes: Different Ways to Cut and Shape

Milling: Like using a rolling pin on your dough, it’s a versatile way to cut and shape.

Turning: Imagine spinning a wheel of dough to make a circular shape, this is for making cylindrical parts.

Drilling: Like making holes for your pizza toppings, this is for adding holes to your part.

5. Lead Time: Need it Fast? It Might Cost More

Standard Lead Time: You have time to plan, so the price is usually more reasonable.

Rush Orders: It’s like needing your pizza delivered right now! You might have to pay a premium.

6. Finishing Touches: Adding Some Extra Pizzazz

Polishing: Making your part shine, like a fancy pizza topping.

Anodizing: Adding a protective layer, like that extra cheese that holds everything together.

Plating: Like adding a golden crust, it adds a decorative and protective layer.

7. Location Matters: Where You Get Your Pizza Matters Too

Labor Costs: If you live in a city with high rent, the pizza guy might charge more. It’s the same with CNC machining.

**How to Get the Best Deal: **

Get Quotes: Talk to a few CNC machining companies and get quotes. Don’t be afraid to ask questions!

Think About Materials: Maybe you can swap a fancy material for a more affordable one.

Simplify Designs: Can you make your design a little less intricate?

Negotiate: Don’t be shy about negotiating, especially if you’re ordering a lot.

Look Around: Sometimes companies in other areas might have better prices.

Key Takeaways:

CNC machining is a great option for creating precise parts, but costs can vary.

The price depends on the material, complexity, quantity, and finishing.

Ask for quotes, be open to negotiation, and consider alternative materials or designs.

Don’t be afraid to do some research and shop around to find the best deal for your project!

Remember, like ordering a pizza, getting CNC machining done right is a combination of quality ingredients, skilled craftsmanship, and finding the best value for your money. Enjoy the process!