When seeking Servicios de mecanizado CNC, obtaining a quote is a critical first step. While a quote may appear straightforward, it often contains essential details and potential pitfalls. This guide will help you navigate CNC machining quotes, ensuring you understand the costs involved and avoid common traps.

I. Components of a CNC Machining Quote

A comprehensive CNC machining quote typically includes several key components:

Costes de material

- Material Type: The specific material being used (e.g., aluminum, stainless steel, titanium).

- Specifications: Details about the material, such as grade and finish.

- Quantity: The number of pieces required.

- Unit Price: Cost per individual piece.

- Total Cost: The overall cost for the materials.

Example: For 6061-T6 aluminum, if you require 100 pieces at $10 per piece, the total cost would be $1,000.

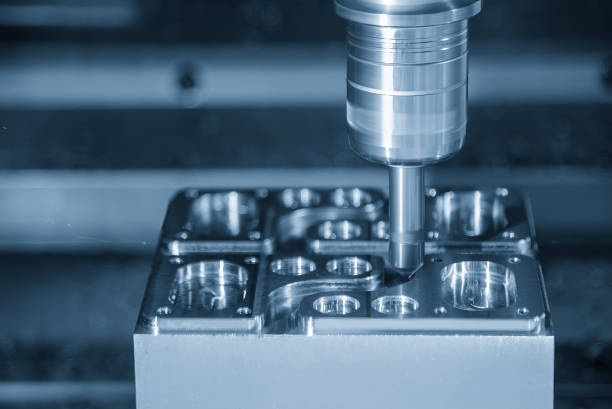

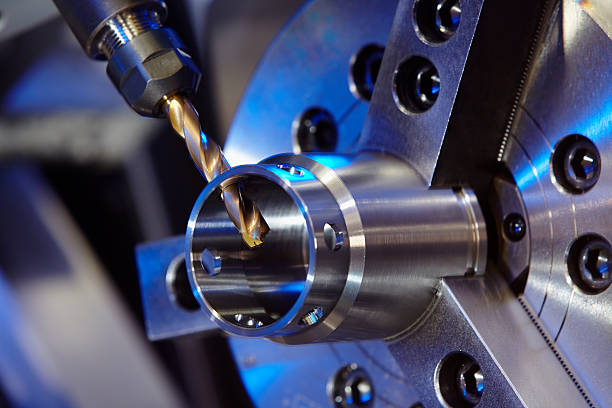

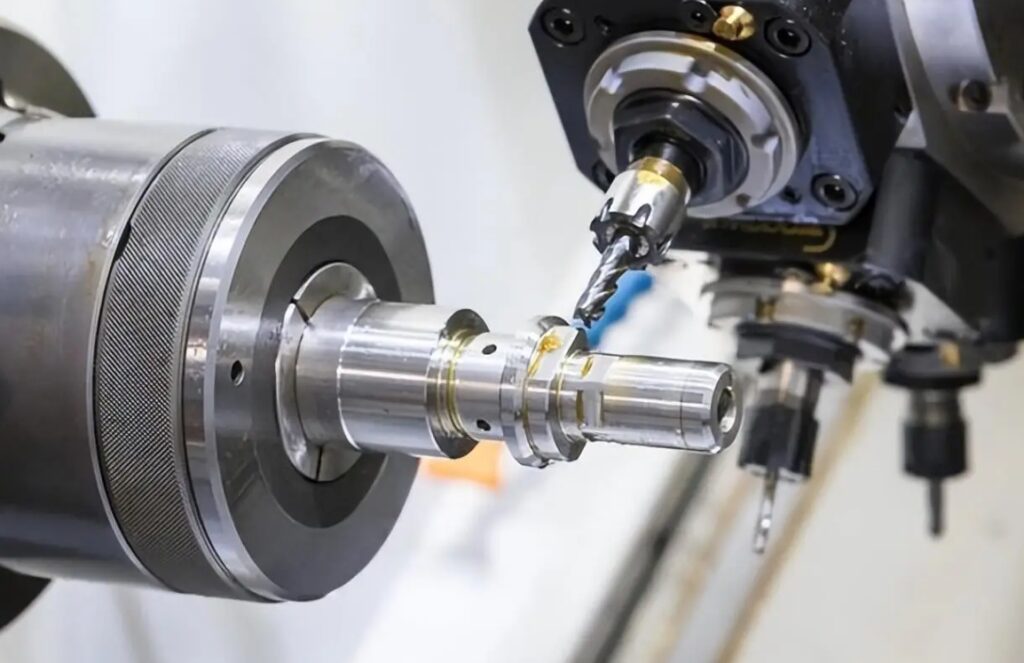

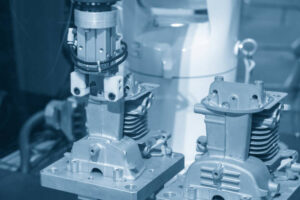

Machining Costs

- Manufacturing Process: The type of machining process being employed (e.g., milling, turning).

- Machine Time: The estimated time the machine will run to produce the parts.

- Equipment Wear: Costs associated with wear and tear on machinery.

- Tool Consumption: Expenses related to tools used in the machining process.

Example: If the milling process takes 10 hours, with $100 for equipment wear and $50 for tool costs, these should be factored into the total machining cost.

Additional Costs

- Shipping: Charges for transporting the finished products.

- Storage: Fees for storing materials or parts before or after machining.

- Management Fees: Costs related to project management or administrative tasks.

Example: This might include $200 for shipping, $100 for storage, and a $50 management fee.

II. How to Analyze CNC Machining Quotes

When you receive a CNC machining quote, it’s crucial to analyze it carefully:

Costes de material

- Verify Specifications: Ensure that the material specifications match your project requirements.

- Compare Prices: Look at prices from multiple suppliers to gauge competitiveness.

- Consider Quality: Evaluate the trade-offs between material quality and performance versus cost.

Machining Costs

- Understand Processes: Familiarize yourself with the manufacturing processes included in the quote.

- Compare Times: Assess the estimated machining times against industry standards.

- Check Rates: Research typical rates for the processes you need.

- Evaluate Technical Capabilities: Ensure the supplier can meet your project’s technical requirements.

Additional Costs

- Verify Charges: Scrutinize shipping and handling fees to avoid unexpected costs.

- Identify Hidden Fees: Look out for undisclosed costs that could inflate the total.

- Negotiate: If possible, discuss any unclear charges with the supplier.

III. Common Pricing Traps to Avoid

Hidden Charges

- Undisclosed Fees: Be cautious of processing fees that are not clearly stated in the quote.

- Material Waste Charges: Some suppliers might charge for material that cannot be used; clarify this upfront.

- Contract Terms: Review all contract terms carefully to avoid surprises later.

Low-Price Traps

- Unusually Low Quotes: Be wary of quotes that are significantly lower than others; they may indicate compromised quality.

- Company Reputation: Research the supplier’s reputation and history in the industry.

- Past Work Examples: Request examples of previous work to assess quality.

Incomplete Quotes

- Missing Details: Avoid quotes that lack key information; they may lead to misunderstandings.

- Request Breakdowns: Always ask for a comprehensive breakdown of costs.

- Get Everything in Writing: Ensure all aspects of the quote are documented.

IV. Protection Strategies

Choose Reputable Manufacturers

- Company History: Investigate the supplier’s track record in CNC machining.

- Customer Reviews: Read reviews to gauge customer satisfaction.

- Verify Certifications: Ensure the supplier has necessary industry certifications.

Review Quotes Thoroughly

- Compare Line Items: Look closely at each line item to understand the costs.

- Question Unclear Charges: Don’t hesitate to ask for clarification on any ambiguous costs.

- Get Written Confirmation: Request formal confirmation of any negotiated terms.

Get Multiple Quotes

- Compare Suppliers: Obtain quotes from several manufacturers to find the best fit.

- Consider Overall Value: Evaluate quotes based on quality, service, and price, not just the lowest cost.

Use Formal Contracts

- Include Specifications: Ensure all project specifications are clearly outlined in the contract.

- Define Payment Terms: Specify payment structures and timelines.

- Specify Quality Requirements: Clearly outline quality standards that must be met.

- Detail Warranty Coverage: Include warranty details for the work provided.

V. Real-World Example

Consider a customer who sought stainless steel parts and received a quote from a supplier offering exceptionally low prices but providing minimal details. After signing the agreement, the customer discovered that the material quality was subpar and the machining processes were inadequate, leading to rejected parts and costly rework. This scenario underscores the importance of thorough analysis and vigilance when evaluating quotes.

VI. Key Takeaways

Understanding CNC machining quotes is crucial for successful project execution. To navigate the quoting process effectively:

- Read Quotes Carefully: Don’t skim through the details; every component matters.

- Verify All Costs: Ensure transparency in all charges to avoid surprises.

- Choose Reputable Suppliers: Partner with manufacturers known for their quality and reliability.

- Get Detailed Contracts: Ensure all agreements are documented thoroughly.

- Compare Multiple Quotes: Consider the total value offered, not just the price.

By following these guidelines, you can avoid hidden costs and make informed decisions when selecting CNC machining services. If you have further questions about CNC machining quotes or need more specific information, feel free to ask!