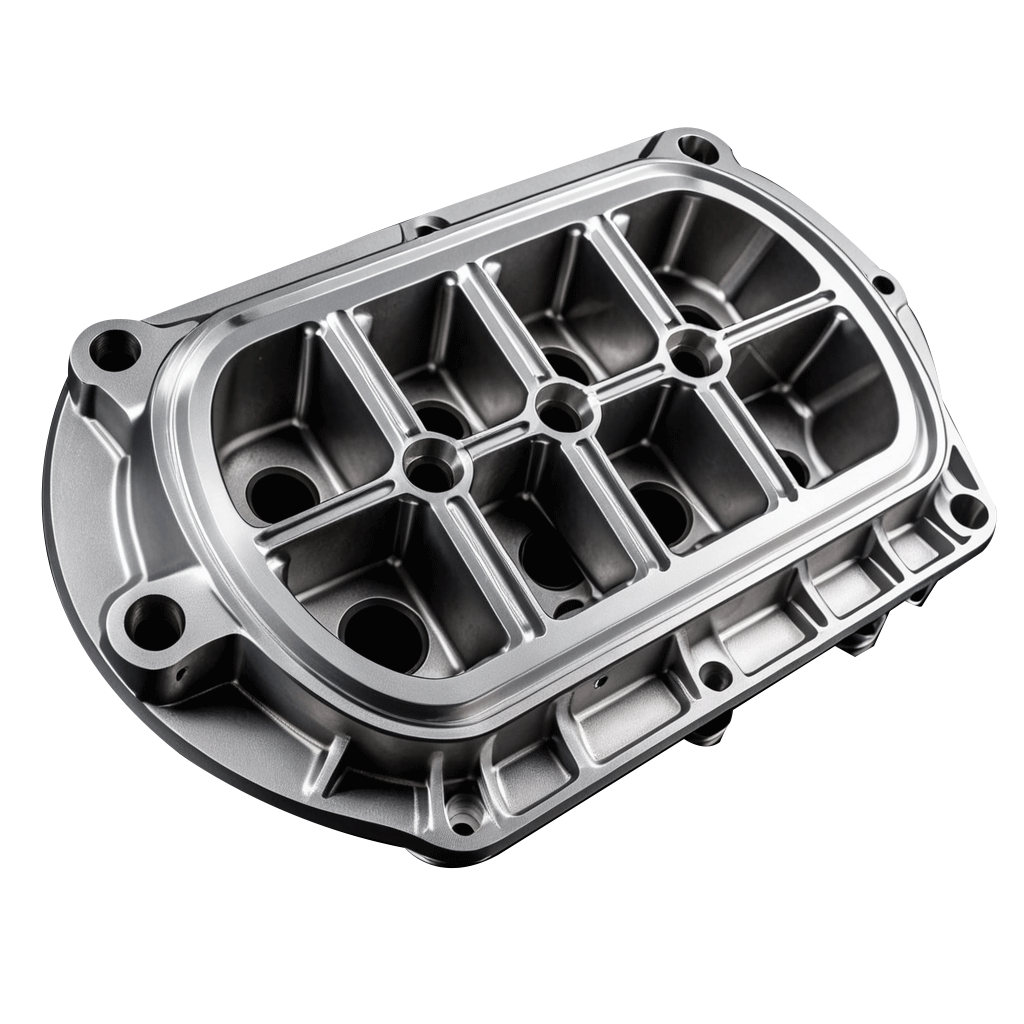

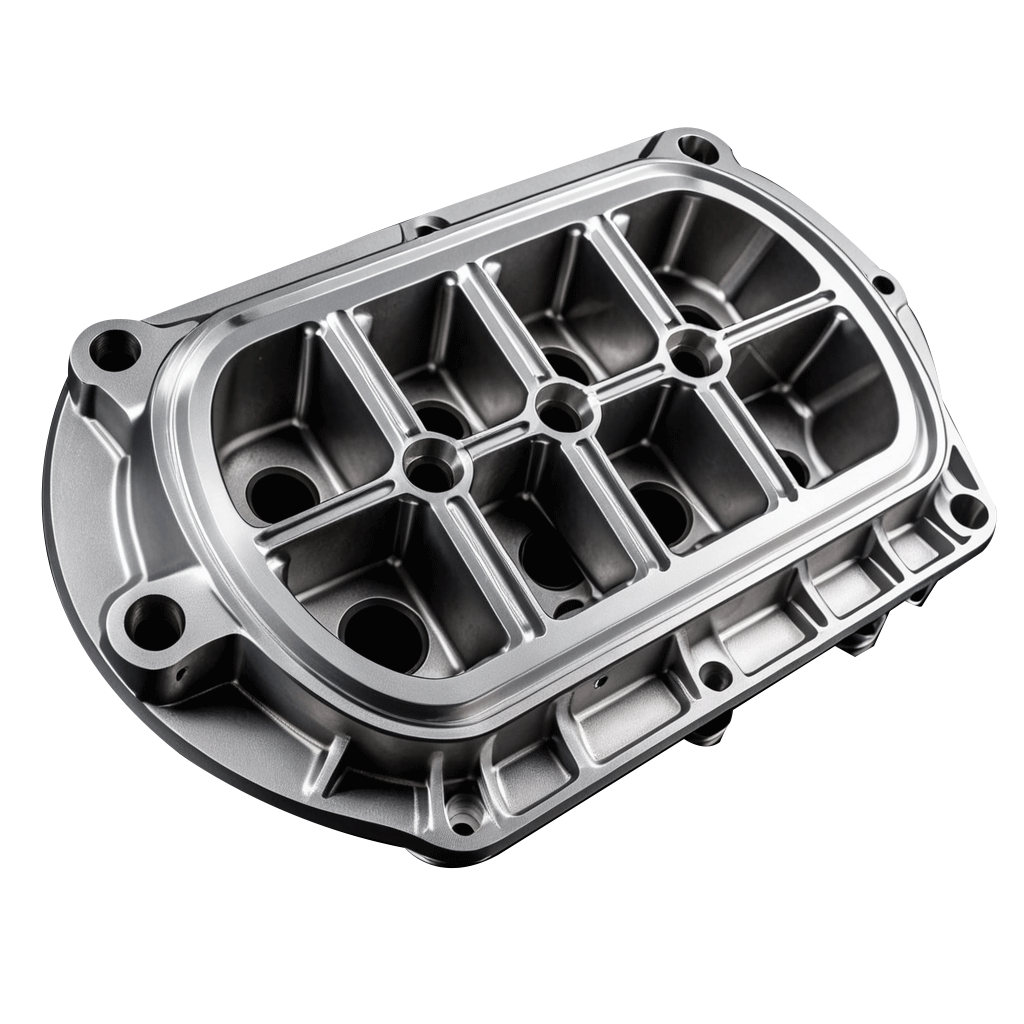

Custom Die Casting Services

Transition from plastic molded prototypes to high-quality custom production parts swiftly. Obtain bulk pricing and Design for Manufacturability (DFM) within one day. Choose from over 30 thermoplastic and thermoset materials.

- Instant Die Casting Quotes & Comprehensive DFM

- Precision Tolerances Down to 0.05mm (±0.002″)

- Die Cast Parts Delivered in as Fast as 3 Days

10 S

Instant Quotes

1 day

Lead time

0 pc

MOQ

0.01 mm

Tolerances

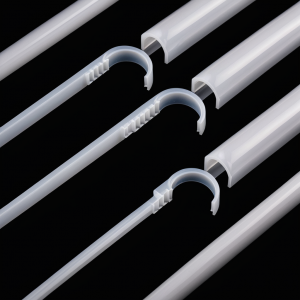

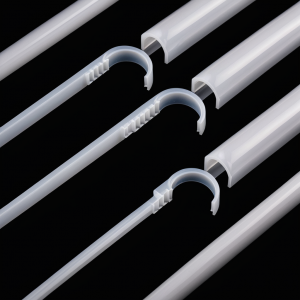

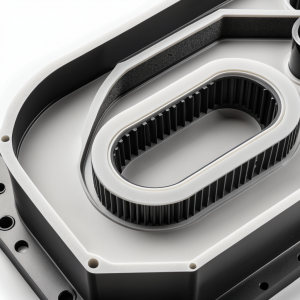

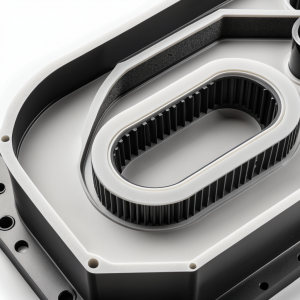

Our Custom Injection Molding Services

With GCH’s injection molding solutions, we tailor parts to exact size, complexity, and volume specifications. Our machinery, ranging from 30 tons to 1800 tons, enables on-demand prototyping and production runs, guaranteeing design precision. Each injection molding order comes with a complimentary design consultation, enhancing product competitiveness. Expect rapid turnarounds with lead times as short as 15 days.

Injection Molding

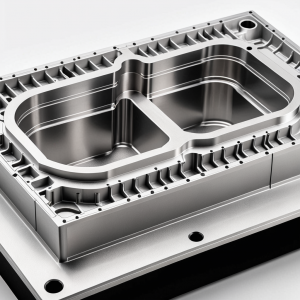

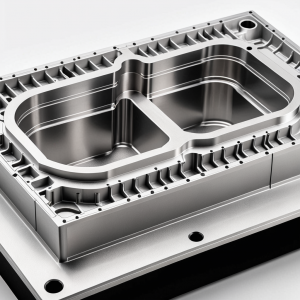

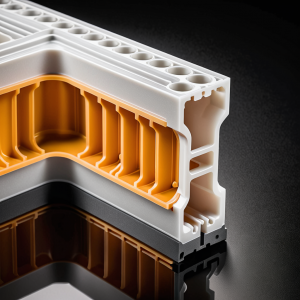

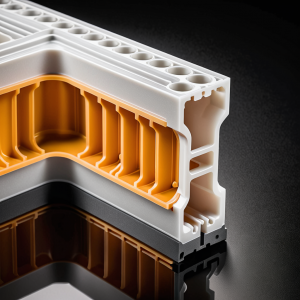

Injection molds are essential for the mass production of accurate plastic molded components. Primarily constructed from steel or aluminum, their fabrication requires intricate design, precise machining, and meticulous assembly.

Plastic Injection Molding

The plastic injection molding process features the use of high pressure to inject molten plastic into a mold, where it cools and solidifies to form the desired shape of the plastic product.

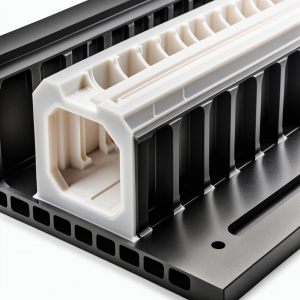

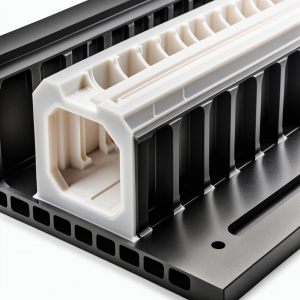

Overmolding

Overmolding is a process where a secondary material is injection molded over a pre-existing part or layer, providing additional features or a finished appearance in a single step.

Insert Molding

Insert molding is particularly useful for creating complex parts with precise dimensions and features, such as electronic components, automotive parts, and medical devices.

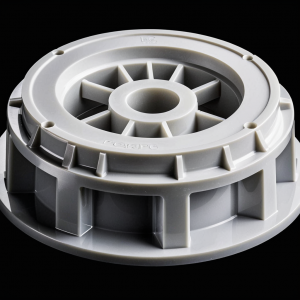

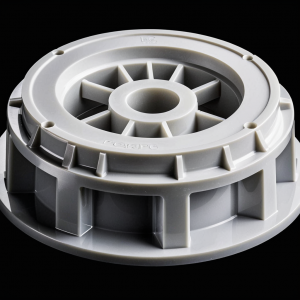

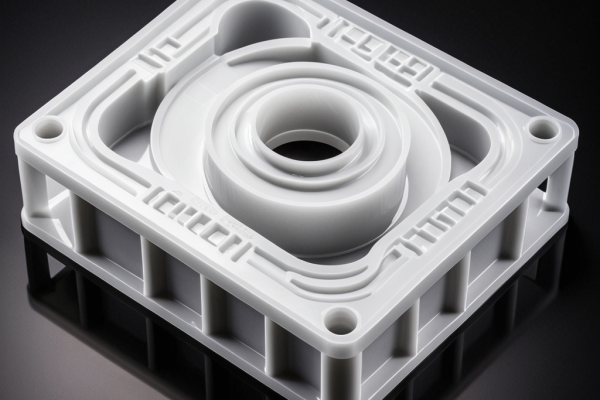

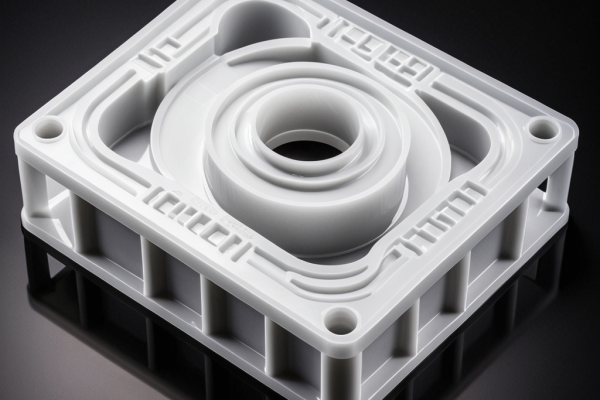

Custom Injection Molded Products by GCH

View the plastic prototypes and on-demand production parts we’ve manufactured for our customers.

Custom Injection Molding Solutions

Explore our on-demand injection molding solutions to seamlessly transition from prototyping to high-quality production.

Rapid Prototyping

Benefit from our rapid injection molding, delivering 1K-100K units quickly at a low cost. Using aluminum or steel molds, we ensure fast turnaround, directly addressing your production challenges and reducing time-to-market.

Low Volume Production

Low volume injection molding elevates your output, delivering 100K-1M units using resilient steel molds. This ensures high quality and consistency, effectively addressing your need for sizable yet precise production runs while maintaining exceptional standards.

Injection Molding Materials

GCH offers common metals for injection molding tooling, and a variety of popular plastic materials.

Injection molding materials

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel:

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Thermoplastic

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

ABS HDPE LDPE PP

PPA PS POM PC

PU Teflon (PTFE) Nylon

PC PMMA PA PEEK

PET

Thermoset

Several thermoset materials for distinct applications due to their unique bonding properties.

Injection Mold Surface Finishes

From prototyping to production, GCH ensures superior quality and reliable functionality. With a wide selection of production-grade metal and plastic materials as well as highly advanced on-demand manufacturing techniques, we offer high-quality products across several industries.

| SPI Finish Standards | Surface Roughness RA (mm) | Finishing Method | Texture | Steels Recommended |

| SPI A1 | 0.012 to 0.025 | 6000 Grit Diamond | Super High Glossy finish | S136 (54HRC) or 8407(52HRC) |

| SPI A2 | 0.012 to 0.025 | 3000 Grit Diamond | High Glossy finish | S136 (54HRC) or 8407(52HRC) |

| SPI A3 | 0.05 to 0.10 | 1200 Grit Diamond | Normal Glossy finish | S136 (300HB) or 718H |

| SPI B1 | 0.05 to 0.10 | 600 Grit Paper | Fine Semi-glossy finish | 718H |

| SPI B2 | 0.10 to 0.15 | 400 Grit Paper | Medium Semi-glossy finish | 718H |

| SPI B3 | 0.28 to 0.32 | 320 Grit Paper | Normal Semi-glossy finish | 718H |

| SPI C1 | 0.35 to 0.40 | 600 Grit Stone | Fine Matte finish | 718H |

| SPI C2 | 0.45 to 0.55 | 400 Grit Stone | Medium Matte finish | 718H |

| SPI C3 | 0.63 to 0.70 | 320 Grit Stone | Normal Matte finish | 718H |

| SPI D1 | 0.80 to 1.00 | Dry Blast Glass Bead | Satin Textured finish | 718H |

| SPI D2 | 1.00 to 2.80 | Dry Blast | Dull Textured finish | 718H |

| SPI D3 | 3.20 to 18.0 | Dry Blast | Rough Textured finish | 718H |

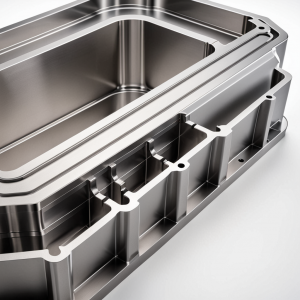

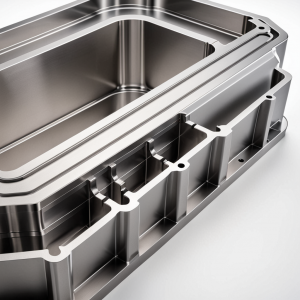

GCH Die Casting Capabilities

| Standards | Description |

| Maximum Part Size | 1200×1000×500 mm 47.2×39.4×19.7 in. |

| Minimum Part Size | 1×1×1 mm 0.039×0.039×0.039 in. |

| Part to Part Repeatability | +/- 0.1 mm +/- 0.0039 in. |

| Mold Cavity Tolerances | +/- 0.05 mm +/- 0.002 in. |

| Available Mold Types | Steel and aluminum tooling. Production grade we provide: Under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

| Machines Available | Single cavity, multi-cavity, and family molds, 50 to 500 press tonnage |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts and basic assembly. |

| Inspection and Certification Options | Quality reports like FAIs, ISO 9001, ISO 13485 |

| Lead Time | 15 business days or less for most orders, 24/7 quotation response |

Classes of Die Casting

We adhere to the five standard categories of SPI mold classifications from Class 101 to 105, aligning expectations for customers and suppliers alike.

| Mold Class | Production Level | Cycles | Applications | Tolerance | Cost | Lead Time |

| Class 105 | Very low | Less than 500 cycles | Prototype testing | ± 0.02mm | Inexpensive to produce a very limited number of product prototypes | 7-10 days |

| Class 104 | Low | Less than 100K cycles | Good for limited-production parts with non-abrasive materials | ± 0.02mm | Fall within low to moderate price ranges | 10-15 days |

| Class 103 | Medium | Less than 500K cycles | For low to medium-production parts | ± 0.02mm | Fall within common price ranges | 10-15 days |

| Class 102 | Medium to high | Less than 1M | Good for parts with abrasive materials and/or tight tolerances | ± 0.02mm | Fairly high price and made with materials of high quality | 10-15 days |

| Class 101 | Extremely high | Over 1M cycles | Extremely high production and fast cycle times | ± 0.02mm | Highest price and made with only the highest quality materials | 10-18 days |

How Custom Die Casting Works?

The Die Casting process involves feeding raw plastic materials into an injection molding machine, melting them down, and then injecting them into an aluminum or steel mold. Upon cooling, a production-grade thermoplastic part is formed and ejected for further use or assembly.

Our Die Casting for Various Industrial Applications

With custom Die Casting Services, GCH supports diverse industry requirements.

The FAQ

Frequently Asked Questions

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Tolerances are crucial in injection molding; without proper specification and control, assembly issues can arise. At GCH, we adhere to the ISO 2068-c standard for molding tolerances, but can accommodate tighter specifications if needed.

We have no minimum order requirement. However, larger quantities will yield more competitive pricing.

Once an order is placed, mold design and creation typically take around 35 days, with an additional 3-5 days for the production of the molded parts.

The cost of our services varies based on several factors such as component size, mold complexity, number of cavities, material type, and post-processing requirements. We provide quotes after analyzing these factors on our platform.

At GCH, we offer a wide range of thermoplastic and thermosetting materials suitable for various applications. Some common materials include ABS, Polycarbonate, Polypropylene, and TPE. For a full list of materials or custom material requests, please contact our customer service.

Yes, GCH offers rapid prototyping services. This allows you to test and verify your design before committing to large-scale production.

Latest Posts

Understanding CNC Machining: A Beginner’s Guide

Precision CNC machining services for custom parts. High-quality, accurate, and efficient solutions for various industries.

Top Materials Used In CNC Machining: A Comprehensive Guide

Precision CNC machining services for high-quality, custom parts. Expert manufacturing for industrial applications.

The Latest Trends In CNC Machining Technology You Should Know

“Precision CNC machining manufacturer offering high-quality custom parts, rapid prototypes, and production services for aerospace, automotive, medical, and industrial applications.”