CNC Turning Services

At GCH, we offer efficient CNC turning services that cater to all your needs, from rapid prototyping to large production runs. Ensure you receive high-quality CNC-turned parts equipped with the precise features you require, all at competitive pricing and swift lead times.

- 0.02 mm Tight Tolerance

- Lead time as fast as 3-5 days

- Automatic DFM Report

30t-1800t

Instant Quotes

12

Surface Finishes

0pc

MOQ

0.025mm

Tolerances

Our CNC Turning Services

Take advantage of the on-demand CNC turning service and get reliable metal and plastic turned parts for your unique projects. With advanced technologies and expert technicians, GCH produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities allow us to deliver turned parts with high accuracy, regardless of the complexity. You will get durable parts from flats to radial and axial holes, slots, and grooves as fast as one day.

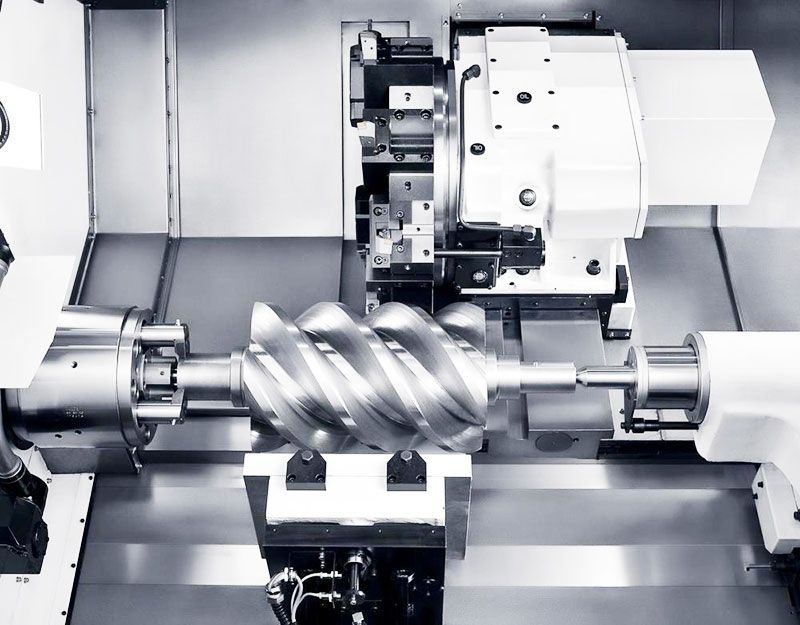

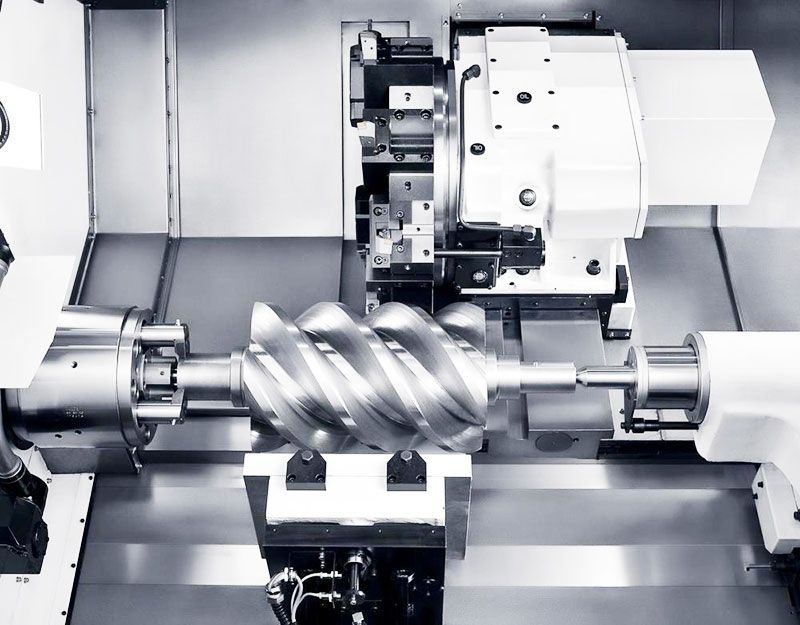

CNC Lathes

Our precision CNC turning lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats. Full automation of these versatile machines allows us to produce hundreds of similar dimensions easier, faster, and cost-effectively.

Gallery of CNC Turning Parts

Why Choose Our CNC Turning Services

GHC is your leading CNC turning company, consistently delivering highly reliable CNC turning services for several industries. Our com

High Precision and Tight Tolerances

Rapid Prototyping and Production

We expedite your product development from prototyping to production. Our quick turnarounds turn designs into prototypes, enabling faster iterations and reduced time-to-market. Our CNC machining is scalable to any production volume.

Advanced Manufacturing Facilities

At GCH, our comprehensive equipment includes Precision CNC milling, turning, and EDM. From prototypes to mass production, we use top materials and technology. Our dedicated technicians work tirelessly for optimal product quality.

IATF16949:2016 Certificated

GCH boasts expert engineers ready to optimize your designs, cut costs, and enhance quality. Trust our team for exceptional advice and unmatched engineering support, ensuring top-tier project results.

From Prototyping to Production

CNC turning is a highly precise and adaptable manufacturing process that utilizes computer-controlled lathes to shape and refine components, making it ideal for rapid prototyping and on-demand production. At GCH, we offer specialized CNC turning services tailored to meet the unique needs of various industries.

Rapid Prototyping

Quickly transform your CAD designs into final CNC-turned prototypes with GCH. Test and refine your concepts, minimize costly turning errors, and accelerate your product’s time-to-market with our precision turning services.

Bridge Production

With GCH’s Bridge Production, smoothly transition from prototype to full-scale CNC turning production. Our process ensures consistent quality, mitigates risks associated with scaling, and delivers precision at every stage of your project.

Want to make your design a reality?

Let's Start

A New Project Today

Contact our engineers immediately and we will quickly help you determine your best solution based on your needs.

CNC Truning Tolerances

GCH is dedicated to delivering precision with our CNC turning tolerance standards. We commit to exact measurements, ensuring clients receive consistent, high-quality results optimized for search visibility. Our standard tolerances for CNC-turned metals adhere to ISO 2768-m, and for plastics, we follow ISO 2768-c.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

Materials for CNC Truning Parts

At GCH, our CNC turning service offers a wide range of materials, ensuring precision and durability. This extensive selection provides our clients with the best options for their unique projects, enhancing product quality and performance.

Aluminum

Aluminum has an excellent strength-to-weight ratio of this metal. It is a great option for the high loading requirements of aircraft brackets and housings. Aluminum also boasts good ductility, stiffness, corrosion resistance, and machinability. Its lightweight properties make it useful for aerospace structural applications like fuselage skin, wing stringers, wing skins, etc.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

These properties make titanium alloys great options for airframes and aircraft engines.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Steel is another metal with application in the production of modern-day automobile parts. This metal is durable and efficient in performance. It also facilitates the production of high-quality parts. It is resistant to corrosion, lightweight, and results in the production of aesthetically pleasing parts. This metal has applications in the production of car brakes, engines, exhaust systems, wheels, etc.

Price: $

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper plays a huge role in comfort, efficiency, and safety in the automotive industry. It is an excellent conductor of electricity, highly ductile, and malleable. It has application in most of the vehicle’s electronic components, including vehicle’s wire harness, radiator, starter motor, alternator, and brake tubes.

Price: $

Lead Time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

Magnesium

Magnesium is lightweight and has excellent castability and high specific strength, which gives it application in the automotive industry. Magnesium has applications in producing engine blocks, gearboxes, clutch housings, wheels and engine cradles, and oil pans.

Price: $

Lead time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

Why Choose GCH

We take an approach that aims to meet your customized needs. We aim to provide long-term prototype overmolding solutions to engineering experts and project managers from design to production. GCH combines cost-effective mold tooling with tech-driven overmolding services that help to make high-quality parts.

No MOQ

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced injection molding cost.

Tight Tolerance and High Quality

Our plastic injection molding process includes vital design considerations to improve moldability and enhance aesthetic appearance. GCH delivers plastic injection molded parts of varying sizes and complexities. Our standard tolerances are defined by ISO 2768 standards, helping us meet tight tolerance requirements.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Injection Molding Specialists

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

How Custom CNC Truning Works?

The CNC turning process begins by feeding raw materials such as metals or plastics into a CNC lathe. The machine then spins the material while precision cutting tools shape it into the desired form. Upon completion, the finished component is removed, ready for further use or assembly in production-grade applications.

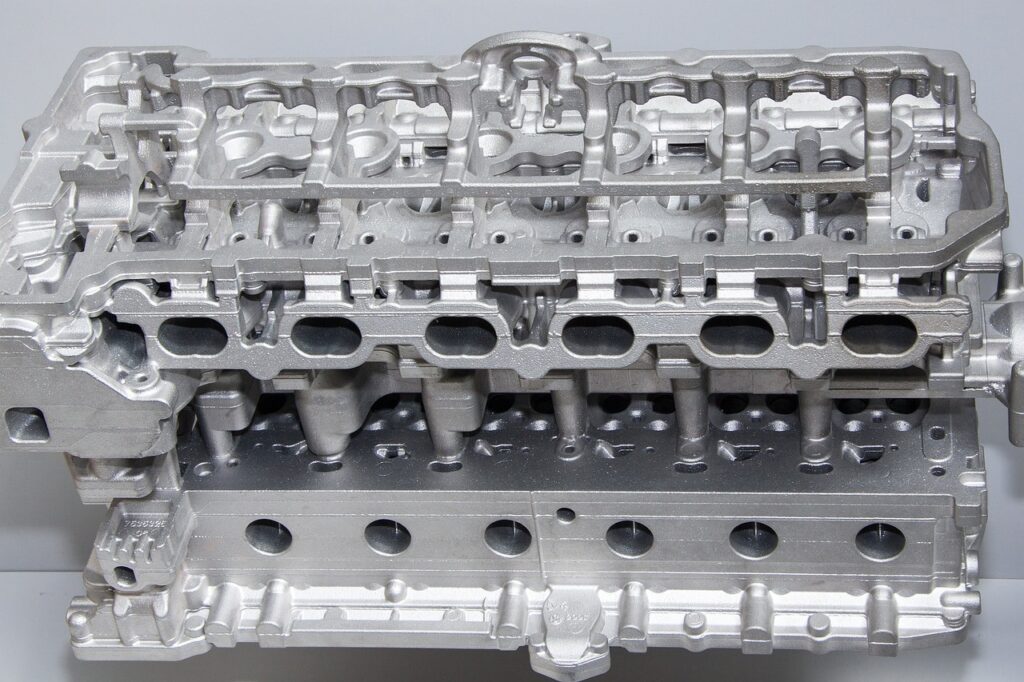

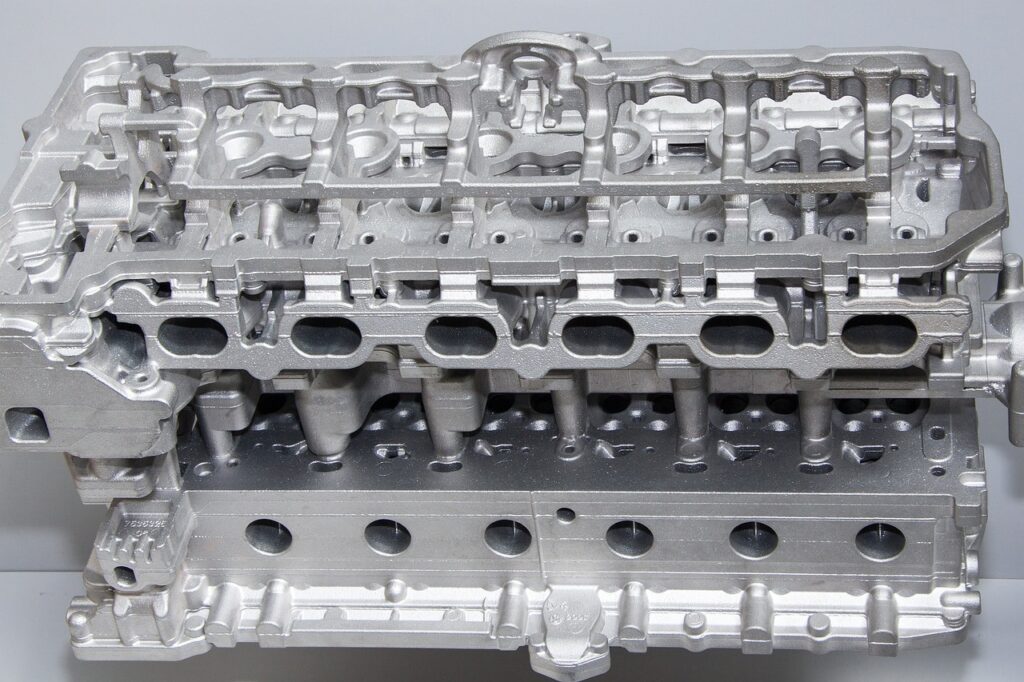

CNC Turning for Various Applications

Dive into GCH’s extensive gallery showcasing some of our completed CNC-turned parts. See firsthand the precision and quality of our work, and feel confident that we can produce your CNC turning project to meet your strict specifications.

The FAQ

Frequently Asked Questions

The CNC turning process is mostly ideal for cylindrical-shaped raw materials. However, several manufacturers also use it for hexagonal and square-shaped workpieces. It is a popular method for making machine parts for microfluidic tools, signage components, surgical instruments, automotive frames, and aerospace parts.

We can turn parts with diameters ranging from 0.5mm to 65mm for stock bars. Our turning capabilities can reach up to 3000 mm for billets.

Yes, our CNC turning services include plastic parts manufacturing. We can produce small or large batch prototypes and production parts from various engineering-grade plastics. Choose from our extensive range of plastic materials and upload your design file to get custom plastic components.

The major difference between CNC milling and CNC lathe is in their machining process. CNC milling involves rotating the cutting tools against a stationary bar stock or workpiece. In contrast, a CNC lather works by rotating the bar stock or workpiece against a stationary tool. CNC milling is more suitable for machining irregular and flat surfaces, while CNC lathes work best for cylindrical or conical parts.

Latest Posts

Understanding CNC Machining: A Beginner’s Guide

Precision CNC machining services for custom parts. High-quality, accurate, and efficient solutions for various industries.

Top Materials Used In CNC Machining: A Comprehensive Guide

Precision CNC machining services for high-quality, custom parts. Expert manufacturing for industrial applications.

The Latest Trends In CNC Machining Technology You Should Know

“Precision CNC machining manufacturer offering high-quality custom parts, rapid prototypes, and production services for aerospace, automotive, medical, and industrial applications.”