TL;DR

| Information | |

| Project Brief | Andrea, a dedicated mechanical engineer from Italy, utilized RapidDirect 5-axis CNC machining to produce a full-body passive exoskeleton that boosts human strength and minimizes physical strain. |

| Industry | Industrial Equipment |

| Technology | CNC machining |

| Materials | Aluminum |

| Surface Finishing | As Machined |

| Challenges | Multiple machining surfaces, right angle U-shaped groove, oblique hole groove |

| Solutions | 5-axis CNC machining |

| Why RapidDirect | RapidDirect’s advanced manufacturing capabilities proved instrumental in fabricating the exoskeleton components with utmost precision. |

| The Result | 4 precision pieces of lats and deltoid components for the exoskeleton. |

Introduction

Driven by his passion for engineering, a passionate mechanical engineer from Italy, Andrea Piccinno, ventured into an expedition to bring the iconic “Iron Man Suit” to life. Andrea dedicated his spare time to turning this extraordinary vision into a reality.

The “Iron Man Suit” represents the epitome of human-machine integration, with its sleek design, advanced functionalities, and incredible capabilities. Andrea’s journey began with a deep fascination for exoskeleton technology and a desire to explore its potential. With the urge to push the boundaries of human-machine interaction, he delved into extensive study and investigation of the exoskeleton field.

He immersed himself in research, exploring existing technologies and scientific literature to understand the intricacies of exoskeleton design, functionality, and applications. Andrea and GCH combined their passion for innovation and commitment to excellence to transform this sci-fi fantasy into a real marvel.

Get Started with 3D-Printed Exoskeleton Components

A full-body passive exoskeleton distributes the weight and physical stress experienced by the user across the entire body. Passive exoskeletons have gained recognition and adoption in various industries, including healthcare, military, manufacturing, etc. They are known for their potential to aid in rehabilitation, enhance physical performance, and improve worker safety.

However, most passive exoskeletons on the market cater to specific body areas, transferring the weight from one body part to another. Andrea’s vision was to develop a full-body version that redirected the weight to the ground, significantly reducing the impact on the user.

In the early stages of his project, Andrea leveraged his 3D printing capabilities to prototype the exoskeleton components. This approach allowed for rapid iterations and proof of concept, enabling him to fine-tune the design and assess its feasibility.

Pursue a Rigid Exoskeleton

As Andrea Piccinno progressed in his journey to develop the “Iron Man Suit,” he encountered a crucial turning point where his prototyping process using 3D printing reached its limits. 3D printing had served as an invaluable tool for preliminary testing and joint setup. However, functional testing and the need for structurally robust components required a different approach.

To achieve a higher level of readiness for testing and ensure the exoskeleton’s reliability and performance, there was a need to fabricate stressed components in aluminum alloy. This is where CNC machining emerged. Its ability to produce complex geometries and tight tolerances made it the optimal manufacturing method. In pursuit of a reliable and efficient CNC machining solution, Andrea collaborated with GCH, a trusted CNC Machining service provider.

Andrea sought CNC machining services for four critical components of the exoskeleton: the lats and deltoids. These components played a pivotal role in the exoskeleton’s functionality, bearing significant stress and contributing to the overall structural integrity of the suit. Andrea used RapidDirect’s user-friendly quotation platform to initiate the collaboration process.

Here, he provided the necessary 3D models and 2D drawings of the components, along with the specifications required for proper assembly. This included features such as threaded connections, bearing slots, and mounting elements for elastic.

How GCH Helps This Project

Smooth and Detailed DFM Analysis

We started by thoroughly reviewing Andrea’s component designs through our extensive Design for Manufacturing (DFM) analysis. One of the primary challenges addressed during the analysis was the presence of multiple machining surfaces in the exoskeleton components. Our experts examined these complex geometries, ensuring that each surface could be accurately machined without compromising the structural integrity of the components.

Additionally, the DFM analysis focused on the oblique hole groove and right-angle U-shaped groove within the components. These intricate features required precise machining techniques to achieve the desired functionality. With valuable insights and recommendations from our engineers, the grooves could be fabricated flawlessly.

Fabrication of Parts According to Specifications

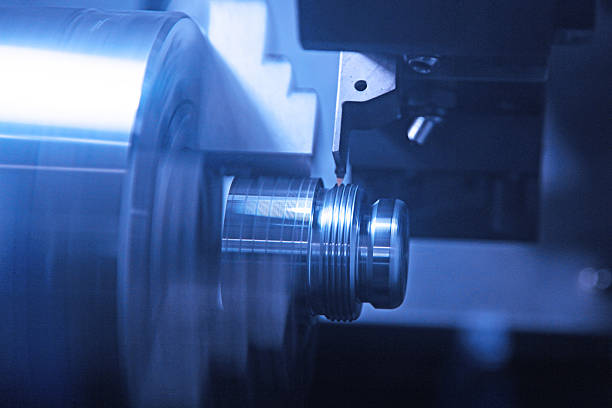

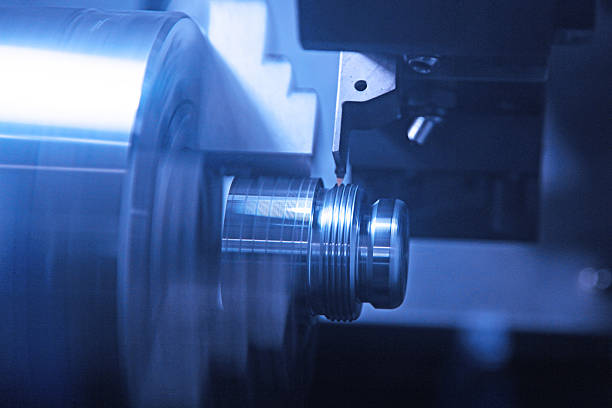

RapidDirect’s advanced manufacturing capabilities proved instrumental in fabricating the exoskeleton components with utmost precision. The machining process involved multiple surfaces, including oblique hole grooves and right-angle U-shaped grooves. The components required great attention to detail, particularly threaded connections and bearing fitting slots.

Our advanced 5-axis CNC machining techniques ensured precise and accurate fabrication. It enabled complex geometries and tight tolerances to be achieved accurately. Electric discharge machining was employed for the U-shaped grooves, while 45-degree angled machining was used for specific features. This approach enabled the creation of intricate features and allowed the components to integrate seamlessly into the overall exoskeleton design.

Future Plans and Milestones

One of the immediate goals is to finalize the exoskeleton prototype by transforming it into a full metal version. This step involves integrating the CNC machined components provided by RapidDirect into the existing prototype. Andrea will carefully evaluate the exoskeleton’s overall performance, functionality, and ergonomics, making any necessary refinements and adjustments.

Comprehensive field testing is planned to validate the exoskeleton’s capabilities and performance. Andrea intends to subject the exoskeleton to real-world scenarios and evaluate its effectiveness in assisting users with load-bearing, mobility, and joint support. The data and feedback gathered from these tests will further enhance the exoskeleton’s design and functionality.

Recognizing the potential of the “Iron Man Suit” project, Andrea aims to showcase the exoskeleton during investment rounds. These rounds will serve as an opportunity to seek external funding and establish strategic partnerships to accelerate the project’s development and commercialization. Andrea will leverage the progress made with the help of GCH to demonstrate the exoskeleton’s viability, market potential, and competitive advantage.

Andrea recognizes that continued collaboration with GCH will be essential to achieve the project’s future milestones. The successful partnership between Andrea and GCH has proven invaluable in terms of technical expertise, manufacturing capabilities, and efficient delivery. As the project progresses, ongoing collaboration with GCH will enable seamless transitions between design iterations, manufacturing phases, and further testing and refinement.