Challenges In Machining Titanium Alloys

Titanium alloys are renowned for their exceptional strength-to-weight ratio, corrosion resistance, and ability to endure extreme temperatures, making them indispensable in aerospace, medical, and marine industries. However, these very properties present significant challenges in machining processes.

One of the primary challenges is titanium’s high strength and hardness, which necessitate the use of specialized cutting tools. These tools, often made from tungsten carbide or cubic boron nitride, are more durable than high-speed steel but still wear out rapidly due to titanium’s abrasive nature. This wear leads to frequent tool replacements, increasing production costs and downtime.

Another challenge arises from titanium’s low thermal conductivity. Unlike metals such as steel or aluminum, titanium does not efficiently dissipate heat generated during machining. This heat buildup can lead to high temperatures, potentially damaging both the cutting tool and the workpiece. To mitigate this, manufacturers often use coolant systems, which can complicate the machining process and add to operational costs.

Titanium’s reactivity at elevated temperatures further complicates machining. At high heat, titanium can react with materials like steel and tungsten, causing galling or seizing. This reactivity not only damages tools but can also mar the surface finish of the titanium part, necessitating additional post-machining processes to achieve the desired quality.

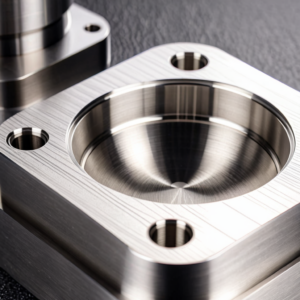

The spring back effect is another hurdle in titanium machining. Due to its elastic nature, titanium tends to return to its original shape after being cut, making precise dimensional control difficult. This elasticity requires the use of rigid machinery and specialized tools to maintain accuracy and prevent distortion.

Additionally, the high cost of titanium alloys intensifies the pressure to achieve precise and efficient machining. Any errors during the process can lead to significant material waste, underscoring the need for skilled operators and advanced equipment to minimize risks.

In conclusion, machining titanium alloys poses several challenges stemming from their unique properties. High strength, low thermal conductivity, reactivity, springback, and cost factors all contribute to the complexity of the process. Addressing these challenges requires careful planning, specialized tools, and skilled personnel to ensure successful outcomes.

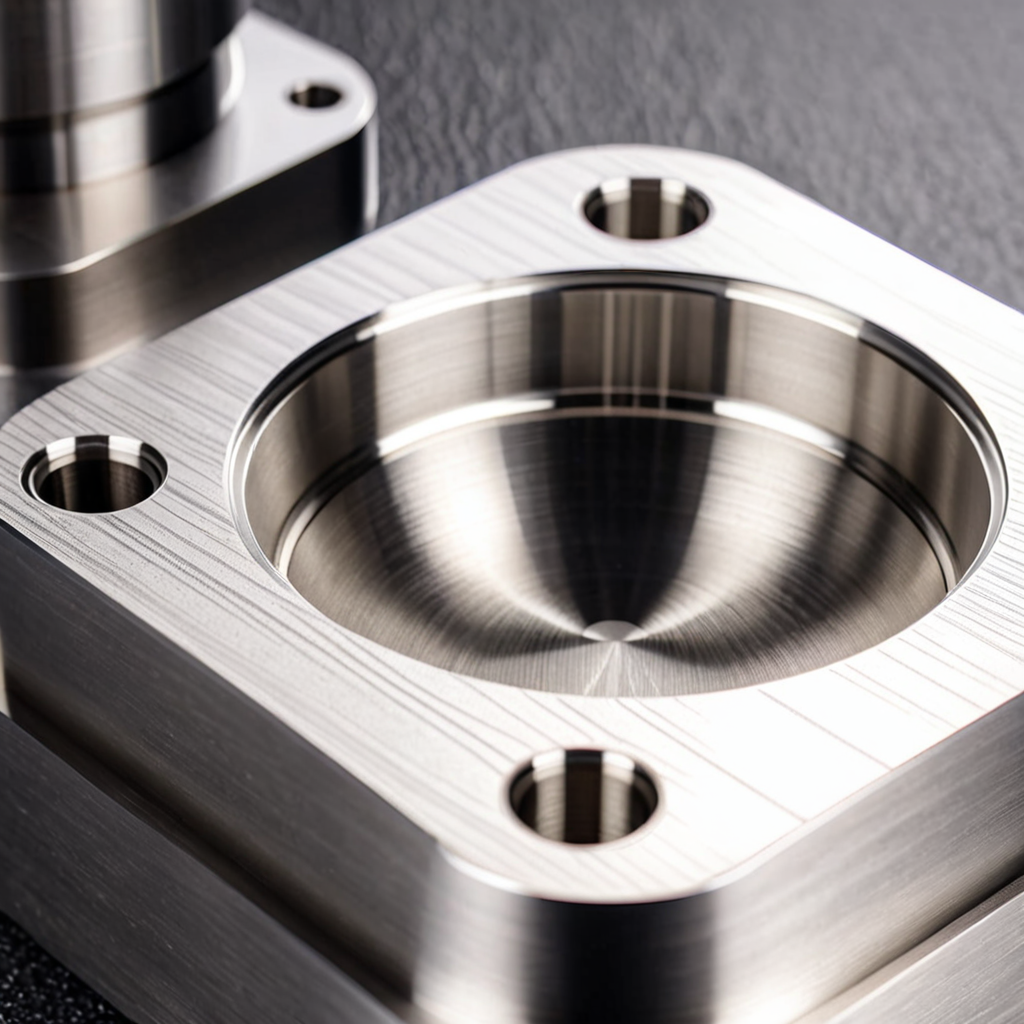

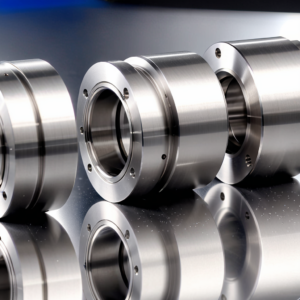

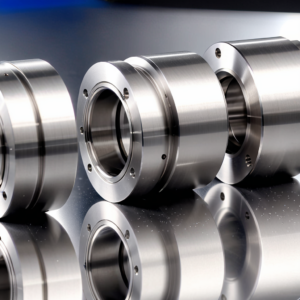

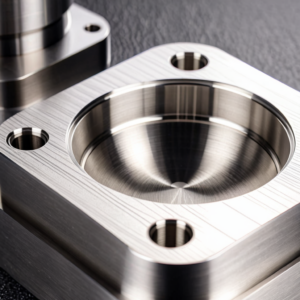

Best Tools And Materials For Titanium Alloy Machining

Titanium alloys are renowned for their exceptional strength, lightweight properties, and corrosion resistance, making them indispensable in industries such as aerospace, medical, and marine. However, these very properties present significant challenges in machining processes. The hardness and strength of titanium alloys generate high temperatures during cutting, which can lead to tool wear and potentially damage the workpiece. To overcome these challenges, selecting the appropriate tools and materials is crucial.

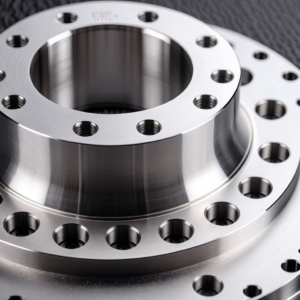

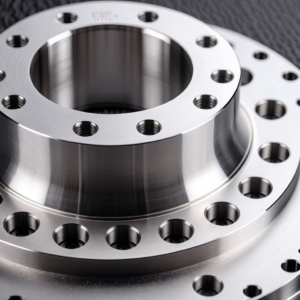

When it comes to tool materials, tungsten carbide is a preferred choice due to its hardness and durability, which are essential for withstanding the rigors of machining titanium. Additionally, tools coated with materials like titanium nitride or aluminum oxide can enhance performance by reducing friction and heat generation. For specific operations, such as grinding, tools tipped with polycrystalline diamond (PCD) or cubic boron nitride (CBN) may be employed, offering superior wear resistance.

The geometry of the cutting tools also plays a pivotal role. A tool with a sharp edge and a positive rake angle can minimize heat buildup and improve machining efficiency. Proper edge preparation is essential to prevent chipping and ensure consistent performance throughout the machining process.

In addition to tool material and geometry, the use of cutting fluids is vital. These fluids act as coolants and lubricants, reducing thermal damage to both the tool and the workpiece. Synthetic or semi-synthetic coolants are often recommended as they provide better thermal management compared to traditional oils.

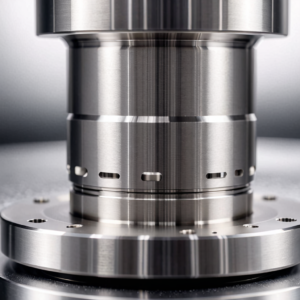

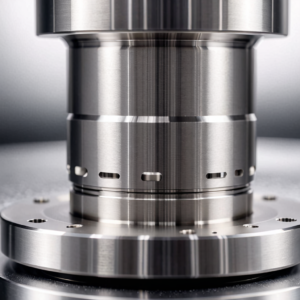

The machine tools themselves must also be of high quality. High-rigidity machines are necessary to maintain accuracy and prevent vibration, which can lead to poor surface finishes. Computer Numerical Control (CNC) machines are typically used for titanium machining due to their precision and ability to maintain consistent parameters, crucial when working with such a challenging material.

Furthermore, the fixtures and workholding systems used in titanium machining must be robust to securely hold the material without causing distortion or damage. Proper clamping techniques are essential to ensure the integrity of the workpiece throughout the machining process.

In conclusion, the successful machining of titanium alloys requires a combination of appropriate tool materials, optimal tool geometry, effective cutting fluids, high-performance machine tools, and reliable workholding systems. Each of these elements contributes to overcoming the inherent challenges of machining titanium, ensuring precise and efficient results.

Optimal Machining Techniques For Titanium Alloys

Titanium alloys are renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making them indispensable in aerospace, medical, and industrial applications. However, these very properties present significant challenges in machining, necessitating specialized techniques to ensure precision and efficiency.

The challenges in machining titanium stem from its inherent toughness and high strength, which can lead to rapid tool wear. Additionally, titanium’s low thermal conductivity results in heat buildup during machining, potentially damaging both the tool and the workpiece. These factors underscore the need for optimal machining strategies tailored to its unique characteristics.

Tool selection is paramount in titanium machining. Tungsten carbide tools are preferred over high-speed steel due to their superior durability and resistance to wear. The geometry of the tool is equally important; sharp cutting edges minimize friction and heat generation. Applying coatings, such as titanium nitride, can further enhance tool longevity by reducing wear.

Coolant usage is another critical factor. Flood cooling with a high-pressure coolant effectively dissipates heat, preventing tool overheating and improving surface finish. This method is particularly effective in maintaining tool life and preventing thermal damage to the titanium alloy.

Cutting parameters must be carefully calibrated. While lower cutting speeds help manage heat and prevent galling, excessively slow speeds can compromise efficiency. Maintaining consistent feed rates is crucial to avoid work hardening, a phenomenon where the alloy becomes harder during machining, leading to tool damage and poor finishes.

Surface finish quality is vital, especially in applications like aerospace and medicine. Employing optimal machining techniques ensures a superior finish, reducing the need for post-machining processes and enhancing part performance.

The expertise of the machinist is equally vital. Experience with titanium alloys enables precise parameter adjustments, crucial for avoiding common issues. The cost implications of improper machining, including tool replacement and material waste, highlight the importance of skilled operators.

In conclusion, mastering optimal machining techniques for titanium alloys is essential for producing high-quality components. By selecting the right tools, employing appropriate coolants, and maintaining precise parameters, industries can ensure the integrity and performance of titanium parts, crucial for their respective applications.