The manufacturing industry has undergone significant transformation over the past century. Initially, simple machine configurations sufficed, as precision was not a critical factor. However, with advancements in technology and mobility, the need for precise components in critical applications such as aerospace and automotive industries has grown exponentially. This demand for exactness has led to the development of precision machining.

This article explores the concept of precision machining in manufacturing, focusing on the essential processes and tools that ensure high precision.

Key Concepts in Modern Manufacturing

Manufacturing has rapidly evolved from simple assemblies managed by numerous technicians to highly automated processes dominated by CNC (Computer Numerical Control) machines. Below are key terms frequently encountered in advanced manufacturing:

Precision Machining

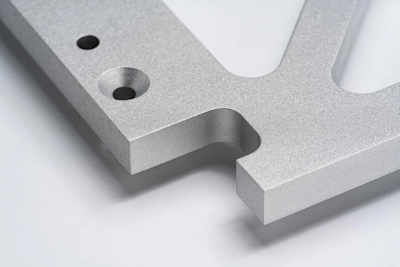

Precision machining involves the use of sophisticated machines designed to fabricate parts with exceptionally high accuracy and strict tolerances. These machines utilize advanced control systems, often guided by CNC technology, to perform precise cutting, milling, turning, or drilling operations.

Precision Manufacturing

Precision manufacturing encompasses a set of practices and processes aimed at producing components with high precision. It involves using precision machines, rigorous quality control measures, and advanced technologies to ensure products consistently meet exact specifications.

CNC Manufacturing

CNC manufacturing utilizes CNC machines programmed to perform designated operations with high precision and efficiency. This technique streamlines the production process and enhances the quality of manufactured parts.

Computer-Aided Design (CAD)

CAD involves creating detailed and precise digital models of physical components on a computer. Designers and engineers use CAD software to construct, modify, analyze, and optimize designs before any physical prototype is made.

Understanding Precision Machining

Precision machining is a subtractive manufacturing process that uses high-speed CNC machines to create complex geometries with exceptional accuracy and strict tolerances. The aim is to produce parts very close to the dimensions of the digital design, with tolerances ideally within a thousandth of an inch. CNC precision machines receive instructions from a computer system and replicate these dimensions in the final part.

Importance of Precision in Modern Machining

Precision machining is crucial for ensuring the operational integrity, safety, and market viability of manufactured products. It is essential for sectors like aerospace and medical devices, where even minor deviations from specified dimensions can lead to severe consequences, including system failures that may jeopardize lives. Precision machining enables flawless integration and dependable performance under rigorous conditions.

Moreover, high-tech components, such as those in electronics and quantum computing, rely heavily on precision machining for producing complex and miniaturized parts. Maintaining stringent precision in machining processes is also vital for meeting the highest quality standards, thereby sustaining a manufacturer’s reputation and building consumer trust.

The Precision Machining Process

Precision machining involves several carefully planned steps to produce a part that perfectly matches its design:

- Design Using CAD (Computer-Aided Design) The process begins with a rough sketch, which is then refined using CAD software to create a graphical model. Popular CAD tools include AutoCAD and SolidWorks, known for their robust 3D design capabilities.

- Conversion to CAM (Computer-Aided Manufacturing) CNC machines require machine-readable code to interpret a graphical model. Modern CAD software includes CAM capabilities to convert 3D models into G-codes and M-codes, which define the cutting tool paths and manage auxiliary functions.

- Material Selection and Preparation Material choice depends on the part’s requirements, machinability, and cost. For example, steel is commonly used for its hardness and strength, while aluminum is preferred for its lightweight properties in aerospace applications.

- Setup of Precision Machinery Setting up the machine involves selecting and calibrating precision tools, checking fluid and coolant levels, and possibly running a dry run to ensure everything is set correctly.

- Execution of Machining Once set up, the machining process begins, with initial stages monitored for adjustments. Technicians may need to calibrate tool positions or modify feed rates to accommodate material variations.

- Post-Processing Steps Precision machined parts may require additional finishing, such as polishing or grinding, followed by quality assurance checks to confirm adherence to precise dimensions.

Types of Precision Machining Machinery

Different CNC precision machines are designed to achieve various degrees of precision:

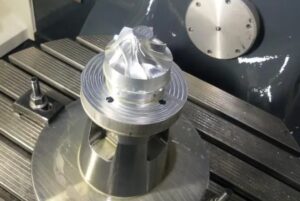

CNC Milling Machines

CNC milling machines use rotary cutters to remove material from a workpiece. They perform operations like pocket milling, profile milling, and surface contouring. Configurations include knee mills, bed mills, turret mills, C-frame, and gantry mills.

CNC Turning Centers (Lathes)

CNC lathes rotate the workpiece against a fixed cutting tool, creating precise symmetrical shapes. Some lathes incorporate live tooling for additional processes such as tapping, milling, and drilling.

Swiss-Type Lathes

Swiss-type lathes feature a linearly moving headstock and guided bush for precise workpiece movement, ideal for producing extremely small and intricate parts.

Multi-Axis Machining Centers

These machines offer movement in multiple axes (up to 12), allowing for intricate and complex parts to be machined without repositioning the workpiece.

Mill-Turning CNC Centers

Combining CNC milling and turning capabilities, these centers perform multiple operations on a single machine, reducing handling between processes.

CNC Grinding Machines

Precision grinders use abrasive wheels to achieve high-accuracy surface finishes and tight dimensional tolerances on parts.

CNC Drill Presses

CNC drill presses feature a stationary workpiece and a rotating drill bit to create precise holes, primarily used for fastener or assembly operations.

Electrical Discharge Machines (EDM)

EDM machines use electric discharges to shape materials, ideal for hard or fragile materials that cannot withstand mechanical stresses.

Laser Cutting and Engraving Machines

Laser machines use high-power lasers to cut, engrave, or mark materials, suitable for both metals and non-metals.

Water Jet Cutters

Water jet cutters use high-pressure water mixed with abrasives to cut materials without introducing heat, preventing material distortion.

Selecting Materials for Precision Machining

The choice of material is critical for precision machining. Here’s a table summarizing popular materials, their characteristics, machinability, and end-use cases:

| Class | Material | Characteristics | Machinability | End Uses |

|---|---|---|---|---|

| Metal | Aluminum | Lightweight, corrosion-resistant | Easy | Automotive parts, aircraft components |

| Stainless Steel | High corrosion resistance, strong | Varies by alloy | Medical devices, marine applications | |

| Brass | Good corrosion resistance, easy to machine | Very easy | Plumbing fittings, electrical connectors | |

| Copper | Excellent conductivity | Moderate | Electrical wiring, heat exchangers | |

| Bronze | Strong, corrosion-resistant | Difficult | Bearings, marine hardware | |

| Titanium | Lightweight, strong, corrosion-resistant | Difficult | Aerospace structures, medical implants | |

| Plastics | ABS | High strength, toughness | Easy | Automotive components, consumer goods |

| PC (Polycarbonate) | Impact-resistant, transparent | Moderate | Safety equipment, optical lenses | |

| PMMA (Acrylic) | Transparent, lightweight | Easy | Signage, displays | |

| POM (Acetal) | High stiffness, wear-resistant | Moderate | Precision gears, electrical components | |

| PA (Nylon) | Strong, wear-resistant | Moderate | Gears, automotive components | |

| PEEK | High temperature and chemical resistance | Difficult | Aerospace parts, medical equipment | |

| Composites | FRP (Fiberglass Reinforced Plastic) | Good strength-to-weight ratio | Moderate to difficult | Automotive body panels, marine vessels |

| Ceramics and advanced materials | Alumina | Excellent hardness, wear resistance | Very difficult | Cutting tools, wear-resistant components |

| Zirconia | High strength, heat resistance | Very difficult | Dental implants, ball bearings | |

| Silicon Carbide | Extremely hard, thermal resistance | Very difficult | High-performance aerospace, nuclear parts |

Considerations for Material Selection

When selecting materials, consider machinability, physical properties, cost, and applications. Hardness and strength are crucial for machinability, with harder materials being more challenging to machine but excellent for tooling. Cost is also a significant factor, especially in high-volume production.

Applications of Precision Machining Across Industries

Precision machining is vital in various industries where parts must fit together seamlessly. Applications include:

| Industry | Specific Applications |

|---|---|

| Aerospace | Aircraft engines, structural components |

| Medical | Surgical instruments, implants, prosthetics |

| Automotive | Gear components, engine parts, couplings |

| Electronics | Connectors, circuit boards, enclosures |

| Tool and Die Making | Molds, dies, cutting tools, jigs and fixtures |

| Energy | Turbine components, drilling equipment |

| Defense | Weapon prototypes, missile systems, armored vehicle parts |

Advantages of Precision Machining Techniques

Manufacturers adopt precision CNC machining for several advantages:

High Accuracy and Tight Tolerances

Precision machining achieves high accuracy and tight tolerances, typically around 0.005 inches, ensuring parts meet exact specifications.

Complexity and Flexibility

Precision machining enables the creation of complex geometries with high accuracy, essential for industries like aerospace and medical. CNC machines offer flexibility, allowing quick design adjustments through software parameters, facilitating efficient prototyping and customization.

Efficiency and Speed

CNC machines significantly speed up machining time due to automation and control systems, making them 200 to 300 times faster than traditional machines. CAD/CAM integration further improves speed and efficiency.

Improved Quality and Reliability

Computerized control ensures identical parts within specified dimensions, reducing errors and minimizing the need for secondary finishing. Precision machining reduces waste and produces consistent, high-quality parts.

Cost-Effectiveness

While initial setup costs are high, precision machining is cost-effective for large-scale and customized production. Automation reduces labor costs, and precise cutting minimizes material waste.

Accuracy vs. Precision in Machining

Accuracy refers to how close a part’s measurements are to design specifications, while precision measures the consistency of output across multiple productions. Precision ensures repeatable accuracy, even if not close to a specific value.

Potential Drawbacks of Precision Machining

High Initial Investment

Advanced functionalities of CNC machines result in high initial costs, with industrial-level machines starting at $100,000.

Complex Setup and Operation

Setting up CNC machines is complex, requiring skilled machinists, adding to labor costs.

Economic Scalability

CNC machining may not be economically viable for large production runs due to high setup costs and time required for machine configuration.

Outsourcing Precision Machined Products

Outsourcing precision machining is practical when demand is infrequent. GCH Process offers comprehensive precision machining services, ensuring each component meets stringent quality standards. Our services include precision CNC milling, turning, grinding, and EDM with tolerances up to 0.01mm.

Conclusion

Precision machining is essential for producing intricate assemblies and micro-parts that must synchronize perfectly. With various CNC machining equipment available, precision machining ensures components meet exact dimensions. As technology advances, the significance of CNC precision machining will continue to grow. Contact GCH Process to learn how we can support your manufacturing goals with precision and reliability.

FAQ

What products are made by CNC machining for the automotive industry?

CNC machined prototypes in the automotive industry can include anything from headlight covers to engines. CNC machining also produces end-use car parts, such as cylinder heads, starter motors, gearboxes, and custom components for rare and vintage cars.

What kind of CNC machine is used in the automotive industry?

Simple or one-sided car parts can be made using various CNC machines. However, complex items like cylinder heads and blocks typically require expensive 5-axis machining centers, which offer a wider range of cutting tool angles and enable the creation of highly complex geometries with tight tolerances.

What materials are used in automotive CNC machining?

Different parts require different materials, including metals and plastics. For instance, manufacturing cylinder blocks and heads often involves aluminum, known for its excellent heat dissipation properties.

By expanding the discussion on precision machining for the automotive industry and including detailed insights into applications, advantages, and comparisons with other technologies, this comprehensive guide provides a well-rounded perspective for readers.