In today’s fast-paced technological world, custom CNC parts have become an indispensable part of various industries. From prototype design to precision manufacturing, custom CNC parts can meet a variety of complex needs, providing unique solutions for your projects. However, finding a reliable, efficient, and reasonably priced supplier among the many options is not an easy task.

This article will provide you with a comprehensive guide to help you understand how to find the right custom CNC parts supplier and make wise decisions in the complex selection process.

Why Choose Custom CNC Parts?

Custom CNC parts offer many advantages, making them the preferred choice for numerous industries:

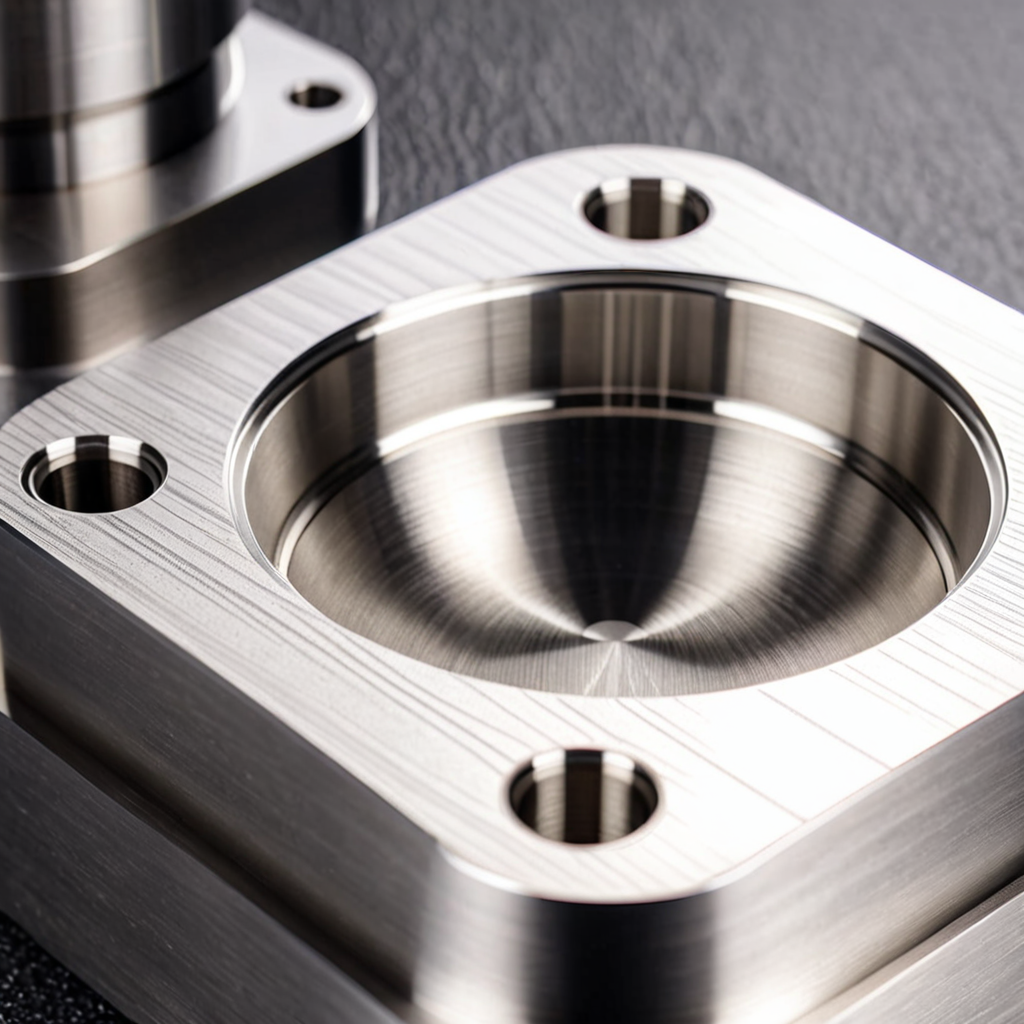

- Precision and Quality: CNC machining technology can achieve high precision, ensuring parts meet design requirements and maintain high-quality standards.

- Complex Designs: CNC machining can realize complex shapes and geometries, meeting the needs for special parts.

- Efficient Production: CNC machining can increase production efficiency and shorten production cycles, meeting the needs for rapid delivery.

- Material Diversity: CNC machining can be applied to a variety of materials, including metals, plastics, woods, etc., meeting the requirements of different application scenarios.

- Cost-Effectiveness: In batch production, CNC machining can reduce production costs and improve product cost-performance.

Key Steps to Finding the Right Custom CNC Parts Supplier

Finding the right supplier is key to ensuring the smooth progress of your custom CNC parts project. The following guide will help you find the most suitable partner:

- Clarify Your Needs:

- Part Dimensions: Clearly define the dimensions of the parts you need to machine, including length, width, thickness, diameter, etc.

- Material Types: Choose the appropriate material types, such as aluminum alloy, stainless steel, plastic, etc.

- Precision Requirements: Set the precision requirements for the parts, such as tolerance ranges, surface roughness, etc.

- Surface Treatment: Determine the surface treatment methods you need, such as sandblasting, anodizing, electroplating, etc.

- Quantity Requirements: Clearly define the number of parts you need, which will affect the processing price and delivery time.

- Design Files: Prepare complete part design files, including CAD files, 3D models, etc.

- Special Requirements: If there are any special requirements, such as material strength, corrosion resistance, etc., be sure to communicate with the supplier.

- Compare Suppliers:

- Online Platforms: Online platforms like Shapeways, Protolabs, Xometry offer convenient custom CNC parts services, allowing you to easily compare the prices and services of different suppliers.

- Local CNC Workshops: Local workshops can provide more flexible custom services and facilitate on-site communication and inspection.

- Specialized CNC Parts Suppliers: Suppliers focused on specific industries or materials, such as medical devices, aerospace, have rich experience and professional technology, providing high-quality parts and services.

- Assess Supplier Qualifications:

- Machining Equipment: Understand the types, models, and performance of the supplier’s machining equipment to ensure they can meet your machining needs.

- Technical Capabilities: Evaluate the supplier’s machining technology level, including machining precision, surface treatment processes, quality control, etc.

- Certifications: Know if the supplier has relevant industry certifications, such as ISO9001, AS9100, etc., indicating a good quality management system.

- Customer Reviews: Check the supplier’s customer reviews to understand their past service quality and customer satisfaction.

- Quotations: Obtain the supplier’s quotations and carefully compare the quotations of different suppliers to ensure reasonable pricing.

- Delivery Time: Ask about the supplier’s delivery time and assess whether they can meet your project’s time requirements.

- Communication and Negotiation:

- Detailed Communication: Communicate in detail with the supplier, clearly expressing your design requirements and machining needs.

- Sample Production: Before formal processing, you can make samples to ensure the processing results meet your expectations.

- Contract Signing: Sign a formal processing contract, clarifying the responsibilities and obligations of both parties to ensure the project proceeds smoothly.

- Frequently Asked Questions:

- Cost of Custom CNC Parts: The cost of custom CNC parts depends on various factors, including material type, part size, precision requirements, machining processes, quantity requirements, etc.

- Common CNC Machining Materials: Common CNC machining materials include aluminum alloy, stainless steel, copper, titanium, plastic, wood, etc.

- How to Obtain Part Design Files: You can design the parts yourself and provide CAD files, or cooperate with the supplier for design.

- CNC Machining Time: The processing time depends on the complexity of the parts, material type, quantity requirements, etc. Generally, the processing time for prototype parts is a few days to a few weeks, and the processing time for batch production may take longer.

Additional Tips for Finding Custom CNC Parts Suppliers

- Utilize Online Resources: Search for relevant information through search engines, industry forums, social media, etc., to find suitable suppliers.

- Attend Industry Exhibitions: Participate in CNC machining industry exhibitions to communicate face-to-face with different suppliers and understand their products and services.

- Seek Help from Professional Organizations: Some professional organizations offer CNC machining service recommendations; you can consult them for professional advice.

- Refer to Industry Cases: Understand how other industries utilize custom CNC parts for inspiration and reference.

Conclusion

Finding the right custom CNC parts supplier is a complex process that requires careful evaluation, screening, and comparison. The guide provided in this article aims to help you make wise decisions in the process of finding a supplier and ultimately find the most suitable partner to complete your custom CNC parts project together.