Comparing 3D Printing and CNC Machining: An In-Depth Analysis

3D Printing and CNC Machining: The Basics

3D printing, also known as additive manufacturing, builds parts layer by layer from a 3D file. This method involves constructing slices that are co-bonded, much like stacking pictures of finite thickness. The term “3D printing” encompasses a variety of methods, materials, accuracies, and costs. In contrast, CNC (Computer Numerical Control) machining is a subtractive process that shapes parts by cutting material from a block using rotating tools or rotating the workpiece. CNC machining is versatile with materials but has some design limitations. This article will delve into the differences, advantages, and disadvantages of 3D printing versus CNC machining.

Understanding 3D Printing

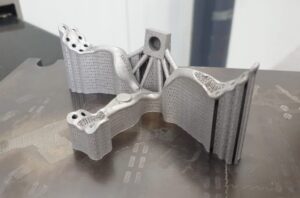

3D printing consists of processes that create parts from digital models by rendering them as slices. These slices are printed sequentially, with each layer bonding to the others. Materials used include extruded polymer filaments, light-sensitive resins, laser-melted powders, filament feedstock, waxes, and even biological materials. Essential tools for 3D printing include CAD software for designing parts, slicer software to convert 3D files into 2D instructions, and a 3D printer.

The first commercially viable 3D printers appeared in the late 1980s. Since then, the technology has rapidly advanced, offering improved aesthetics and material efficiency. 3D printing requires minimal manual intervention, making it suitable for creating complex parts.

Advantages of 3D Printing

- Speed and Efficiency: 3D printing can produce net shape parts quickly, without the need for extensive setup or manual programming required in CNC machining.

- Cost-Effectiveness: Generally, 3D printing is less expensive than CNC machining, particularly for complex shapes. It’s common for CNC parts to be significantly more expensive than 3D printed ones.

- Ease of Use: Modern 3D printers are often office-friendly and require minimal setup skills. They are increasingly capable of meeting various production needs.

Disadvantages of 3D Printing

- Material Strength: 3D printed parts can have varying strength, sometimes significantly lower than the material’s native properties. CNC machining typically maintains the material’s integrity, resulting in stronger parts.

- Precision: While 3D printing can achieve good dimensional accuracy, it struggles with high precision. CNC machining offers superior accuracy through controlled processing.

- Surface Finish: 3D printed parts often have rough, stepped surfaces. CNC machining can produce extremely smooth and uniform finishes with appropriate programming.

Understanding CNC Machining

CNC machining utilizes pre-programmed software to control machine tools, shaping parts through precise cutting. This technology, developed in the mid-20th century, employs various machines like lathes, mills, and grinders. CNC machining is ideal for parts requiring high strength, precision, and smooth surfaces.

Advantages of CNC Machining

- Material Versatility: CNC machining can work with virtually any rigid material, maintaining its full properties. This makes it superior for applications demanding high material strength.

- Precision and Accuracy: CNC machines can achieve very high precision, crucial for parts that require tight tolerances and exact dimensions.

Disadvantages of CNC Machining

- Setup Complexity: CNC machining requires significant setup, including programming and creating mounting tools, making it less efficient for small batches compared to 3D printing.

- Material Waste: As a subtractive process, CNC machining generates more waste material compared to the additive nature of 3D printing.

Comparative Overview

| Attribute | 3D Printing | CNC Machining |

|---|---|---|

| Material Availability | Limited | Extensive |

| Part Design Flexibility | High | Limited by tool access and geometry |

| Precision | Typically around 0.2 mm | Can achieve 0.005 mm |

| Operator Skill Requirement | Low | High |

| Speed | Quick setup, slower build | Slow setup, fast cutting |

| Surface Finish | Rough, stepped | Smooth, precise |

| Strength | Varies, often lower | High, as per native material |

| Cost | Lower | Higher |

Volume and Lead Time Comparison

For low to medium volumes, 3D printing is cost-effective due to its minimal setup costs. CNC machining, while expensive initially, becomes more economical with higher volumes due to its ability to produce multiple parts from a single setup efficiently.

Material Considerations

CNC machining is versatile, handling a wide range of engineering materials while preserving their properties. 3D printing is limited by the materials supported by specific processes and often results in parts with weaker properties due to anisotropic construction and other process-related factors.

Alternative Methods

Injection Molding: Suitable for high-volume production, injection molding produces net shape parts efficiently but involves significant upfront tooling costs, making it less viable for low-volume or prototype production compared to 3D printing and CNC machining.

Conclusion

In summary, while 3D printing offers advantages in cost and setup time, CNC machining excels in precision, material versatility, and part strength. The choice between the two methods depends on the specific requirements of the project, including material properties, design complexity, volume, and precision needs.

For more detailed information or to request a quote, contact a GCH representative. GCH offers comprehensive manufacturing capabilities, including 3D printing and CNC machining, to meet all your production needs.

4o