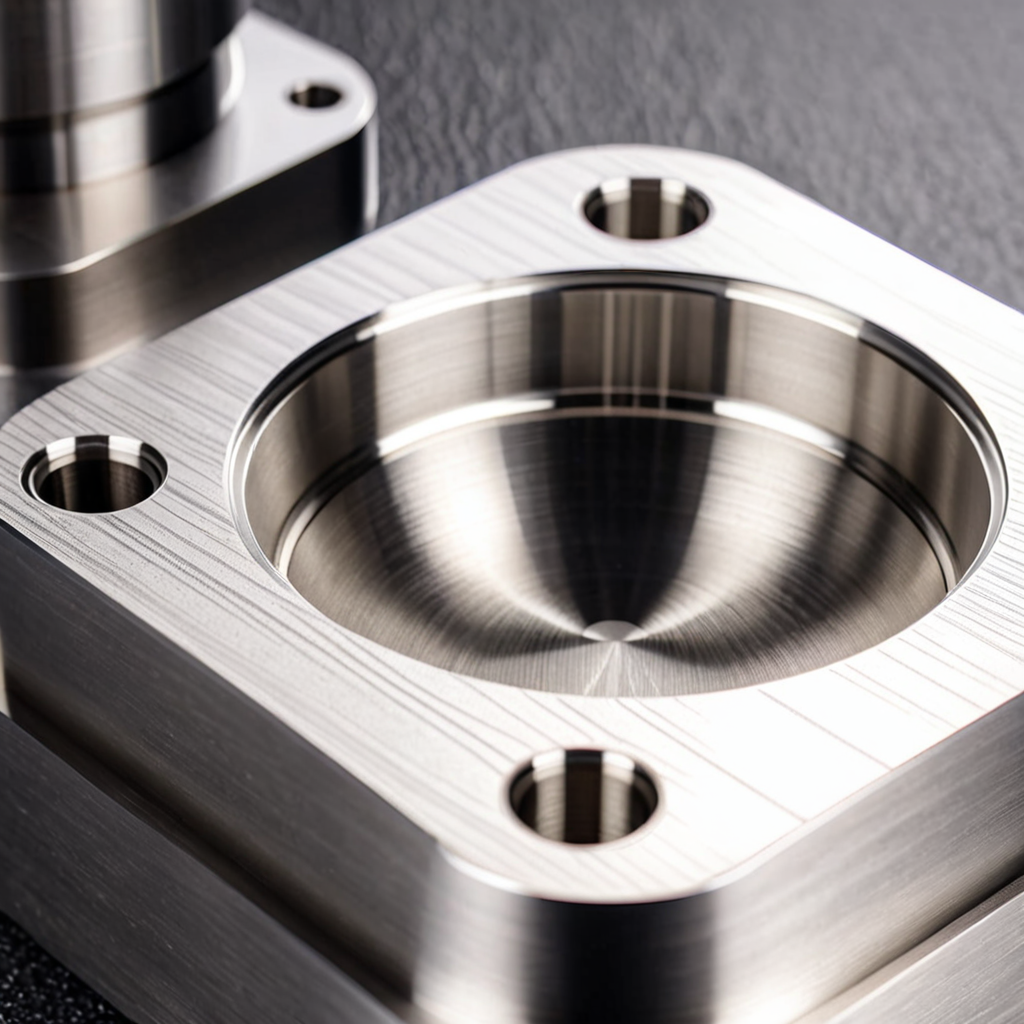

The whirring of CNC machines, the precise dance of cutting tools, and the creation of intricate parts—this is the world of CNC machining. At the heart of this process lies the CNC programmer, the individual responsible for translating designs into the code that guides the machine. However, a growing concern within the industry is the increasing number of programmers who lack crucial hands-on machining experience. This article will delve into the critical importance of this practical knowledge, highlighting the challenges, potential pitfalls, and best practices for success in the field.

The allure of CNC programming is undeniable. The field offers a blend of technical skill, problem-solving, and creative design. However, a purely theoretical approach, neglecting the fundamental principles of machining, can lead to costly mistakes and potentially hazardous situations. The reality is that while software proficiency is vital, it’s only one piece of a much larger puzzle. A programmer without a grasp of the physical realities of machining is like a conductor who’s never heard an orchestra play—they might understand the score, but lack the crucial context to lead effectively.

The Importance of Machining Experience: More Than Just Theory

The advantages of a solid machining background for CNC programmers extend far beyond simple theoretical knowledge. Understanding the physical interactions between the cutting tool, the workpiece, and the machine itself is paramount. This practical understanding allows programmers to:

Predict Material Behavior: The behavior of different materials under cutting forces is crucial. Experience allows programmers to anticipate issues like chip formation, tool wear, and potential material deformation. A programmer who’s only seen material properties on a datasheet might underestimate the impact of factors like work-hardening or springback, leading to inaccurate parts.

Craft Realistic Toolpaths: Designing efficient and safe toolpaths is a complex art, not just a software exercise. Experienced programmers instinctively understand factors like tool engagement, optimal feed rates, and depth of cut. They can anticipate potential problems, such as tool chatter or excessive heat buildup, leading to improved surface finishes and longer tool life. A programmer lacking this understanding might create toolpaths that are theoretically correct but practically disastrous, leading to broken tools, damaged parts, or even machine damage.

Efficiently Troubleshoot Problems: Even the most meticulously crafted programs can encounter unforeseen issues. Experienced programmers can leverage their practical knowledge to quickly diagnose the root cause of problems, whether it’s a dull tool, incorrect clamping, or a flaw in the material. This rapid problem-solving capability significantly reduces downtime and increases overall efficiency. Without this experience, troubleshooting can become a time-consuming and frustrating process of trial and error, potentially halting production and significantly impacting project timelines.

Optimize Programming for Efficiency: Practical experience informs decisions regarding tool selection, cutting strategies, and overall program efficiency. An experienced programmer understands how to minimize material waste, reduce machining time, and optimize tool life, leading to significant cost savings and increased productivity. Conversely, a programmer lacking practical experience might create programs that are technically sound but unnecessarily inefficient, leading to increased costs and reduced profitability.

Prioritize Safety: Understanding the mechanical aspects of machining is crucial for prioritizing safety. An experienced programmer can anticipate and mitigate potential hazards associated with improper toolpaths, excessive cutting forces, or unexpected material behavior. This understanding translates into safer working conditions for both the machine and the operators.

Challenges Faced by Programmers Lacking Machining Experience:

The lack of hands-on experience manifests in numerous ways:

Unrealistic Toolpaths: The most common issue is creating toolpaths that are theoretically correct but impractical. This can result in excessive tool wear, tool breakage, poor surface finishes, or even collisions between the tool and the workpiece, leading to scrapped parts and wasted materials.

Ineffective Troubleshooting: When a program malfunctions, a programmer lacking machining experience may struggle to diagnose and resolve the problem. This can lead to significant downtime, delaying production and increasing costs. They might resort to trial and error, further increasing the risk of damage to the machine or the workpiece.

Increased Programming Time & Costs: The combination of inefficient toolpaths and prolonged troubleshooting significantly increases the time and cost associated with CNC programming. This directly impacts the profitability of projects and can lead to missed deadlines.

Higher Risk of Machine Damage: Poorly designed programs can lead to serious machine damage. Excessive forces, improper tool engagement, or unexpected vibrations can result in damage to the machine’s components, requiring costly repairs and prolonged downtime. This risk is significantly heightened when programmers lack the practical knowledge to anticipate and mitigate potential problems.

Bridging the Gap: Solutions and Best Practices

The good news is that the skills gap can be bridged. Several strategies can help aspiring programmers gain the necessary practical experience:

Formal Machining Training: Investing in structured machining training programs provides a foundational understanding of material properties, cutting techniques, and safety procedures. These programs often combine theoretical knowledge with hands-on practice, providing a comprehensive learning experience.

Mentorship Programs: Pairing aspiring programmers with experienced machinists provides invaluable hands-on guidance and mentorship. Experienced machinists can offer valuable insights, troubleshoot challenges, and guide the programmer’s development.

Hands-on Practice: Even without formal training, seeking opportunities to work alongside experienced machinists or volunteering in machine shops can provide invaluable practical experience. This hands-on experience allows programmers to see how theory translates into practice, reinforcing their understanding and improving their problem-solving skills.

Effective Use of Simulation Software: While simulation software is a valuable tool, it should not replace hands-on experience. Programmers should use simulations to test and refine their programs, but they should always be aware of the limitations of these simulations and the importance of real-world verification.

Collaboration with Machinists: Effective collaboration between programmers and machinists is key to creating efficient and safe CNC programs. Regular communication and feedback loops help ensure that the programs are both theoretically sound and practically viable.

Conclusion:

The importance of hands-on machining experience for CNC programmers cannot be overstated. While software proficiency is essential, it is merely one component of a much larger skillset. A deep understanding of materials, cutting tools, machine capabilities, and troubleshooting techniques is crucial for creating efficient, safe, and cost-effective CNC programs. By investing in appropriate training, mentorship, and collaboration, the industry can bridge the skills gap and ensure that future CNC programmers possess the knowledge and experience necessary to excel in this dynamic and ever-evolving field. Ignoring this critical need will only lead to increased costs, reduced productivity, and potentially hazardous working conditions. The time to prioritize practical experience is now.