Amidst the thriving global manufacturing landscape, CNC machining factories in China are increasingly becoming the preferred partners for international enterprises. These factories are not only renowned for their precision and efficient production but also attract global attention with their unique strengths. So, why are more and more international companies choosing to collaborate with Chinese CNC machining facilities? Let’s delve into the advantages of Chinese CNC machining from various perspectives.

Technological Innovation and Equipment Upgrades

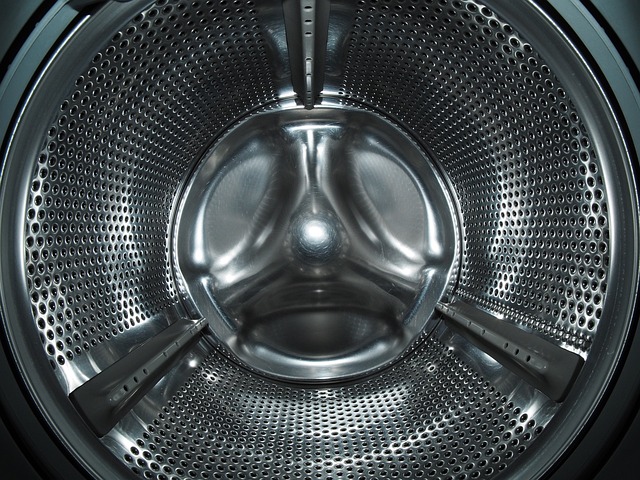

Chinese CNC machining factories have become global leaders in technology and equipment. Many have invested heavily in advanced CNC machine tools and continue to innovate technologically. Compared to traditional manual processing, CNC machining offers superior production solutions to global customers with its high precision, strong repeatability, and high efficiency.

Five-axis Machining

Many Chinese CNC factories have mastered complex five-axis machining techniques, capable of handling more intricate parts and geometric shapes. This is particularly important for industries requiring high precision and complexity, such as aerospace, medical equipment, and automotive manufacturing.

Automated Production Lines

Numerous Chinese CNC factories have achieved automated production, which not only increases production efficiency but also reduces human errors, ensuring product consistency and quality.

Outstanding Cost-effectiveness

Cost-effectiveness is undoubtedly one of the main reasons many enterprises opt for Chinese CNC machining factories. China’s manufacturing industry still has extremely competitive costs on a global scale, especially in terms of labor and production scale. By partnering with Chinese CNC machining factories, businesses can significantly reduce production costs while maintaining product quality.

Labor Advantage

Although labor costs in China have risen in recent years, they remain relatively low compared to Western markets. This allows Chinese factories to offer highly competitive prices.

Scale Production

Chinese CNC machining factories typically have the capacity for large-scale production, efficiently handling orders ranging from small to large batches. This not only further reduces costs but also provides customers with flexible order options.

Globalized Logistics Network and Rapid Delivery

China boasts one of the world’s most developed logistics networks, which provides strong support for CNC machining factories to quickly respond to global market demands. Many factories are located near major ports and international airports, significantly reducing the time from production to delivery.

Efficient International Shipping

Whether you require sea, air, or rail transport, Chinese CNC machining factories can swiftly deliver products worldwide through a mature logistics network.

Rapid Market Demand Response

In today’s fast-paced market, rapid response and delivery are crucial. The efficient production and logistics network of Chinese factories ensure that clients’ projects proceed on time, minimizing losses due to delivery delays.

Exceptional Quality Control

In recent years, Chinese CNC machining factories have made significant progress in quality control. Most leading Chinese CNC factories have obtained international quality management system certifications, such as ISO 9001, ISO 13485, and more.

Stringent Inspection Processes

Many factories use advanced quality inspection equipment, such as Coordinate Measuring Machines (CMM) and laser scanners, to ensure the precision and consistency of each part.

Real-time Quality Monitoring

During the production process, many factories conduct real-time quality monitoring to ensure that each part meets the customer’s specifications.

Wide Material Selection

An excellent Chinese CNC machining factory typically can handle a variety of materials, from common aluminum alloys and stainless steels to complex titanium alloys and engineering plastics. This material diversity enables Chinese CNC machining factories to adapt to the needs of various industries.

Metal Materials

Including aluminum, stainless steel, copper, titanium, etc., widely used in industries such as automotive parts, machinery, electronics, and more.

Non-metal Materials

Such as high-strength plastics, nylon, commonly used in consumer electronics, medical devices, and aerospace equipment.

Flexible Order Handling Capability

Another notable advantage of Chinese CNC factories is their flexible order handling capability. Whether it’s small-batch customized products or large-batch production orders, CNC machining factories can quickly adjust according to the specific needs of customers.

Rapid Prototyping

Chinese CNC machining factories can quickly provide samples, which helps customers test and optimize products before production, reducing subsequent mass production issues.

Batch Production

Regardless of order size, Chinese factories can flexibly adjust production lines in a short time to ensure timely delivery.

Environmental and Sustainable Production

As global awareness of environmental protection increases, more and more Chinese CNC machining factories are adopting environmentally friendly production methods to reduce their environmental impact. Many factories have obtained environmental certifications, using low-energy equipment and reducing waste generation during production.

Additionally, many Chinese factories are exploring the use of renewable energy to further reduce their carbon footprint. This is particularly attractive for international companies with strict requirements for sustainable development.

How to Choose the Right Chinese CNC Machining Factory?

Although China has many excellent CNC machining factories, choosing the right partner requires caution. Here are some important considerations when making a selection:

Technical Capability

Ensure the factory has the equipment and technology you need, especially in high-precision machining and complex part manufacturing.

Quality Certifications

Look for factories with ISO certifications, which means their production processes meet international standards and can provide reliable quality assurance.

Communication Skills

Choose factories that can communicate clearly and efficiently, which will help reduce issues in production and ensure your project proceeds smoothly.

Customer Reviews and Reputation

Review the factory’s customer feedback to understand their performance in cooperation, especially in terms of on-time delivery and quality control.

In Summary

In conclusion, Chinese CNC machining factories offer reliable solutions to global customers with their cost-effectiveness, advanced technology, flexibility, and robust logistics network. Whether you need small-batch customized parts or large-batch production, Chinese CNC machining factories can meet your needs.

By partnering with Chinese factories, you can not only obtain high-quality products but also enjoy more competitive prices and rapid delivery times. If you are looking for a partner that can provide one-stop CNC machining services, a Chinese CNC machining factory is undoubtedly your best choice.