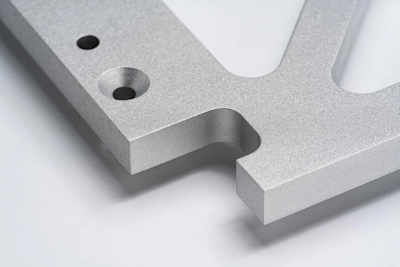

At GCH Process, we specialize in delivering top-notch custom aluminum parts through our advanced CNC machining services. Our focus is on providing high precision, fast delivery, and cost-effective solutions with no minimum quantity requirements. Start your project with us today with costs as low as $150.

Why Choose GCH Process?

- No minimum quantity

- Starting costs as low as $100

- Rapid delivery from 3 days

- 24/7 design and technical support

Service Overview

- Processes: CNC Milling, CNC Turning

- Lead Time: As fast as 3 days for rapid prototype samples

- Tolerance: With drawing: as low as +/- 0.005 mm; Without drawing: ISO 2768 medium

- Price: Starting from $100 for custom aluminum part projects

- Alloys: 6061-T6, 7075-T6, 7050, 2024, 5052, 6063

- Applications: Automation components, automotive parts, aerospace components

- Finishings: Alodine, Anodizing, PTFE, ENP, Blasting, Nickel Plating, Powder Coating, Polishing

About Aluminum Material

Aluminum is the preferred metal for CNC machining, particularly 6061 aluminum, due to its excellent strength-to-weight ratio, low cost, recyclability, and machinability. At GCH Process, we offer precision machining with multiple aluminum alloys to meet diverse industry needs.

Aluminum Alloys We Work With:

- 6061 Aluminum: Highly versatile, corrosion-resistant, non-magnetic, and heat treatable.

- 7075 Aluminum: Known for high strength, suitable for high-stress applications, corrosion-resistant, non-magnetic, and heat treatable.

- 7050 Aluminum: Ideal for high-stress corrosion-resistant applications, heat treatable, non-magnetic.

- 2024 Aluminum: Offers a high strength-to-weight ratio, heat treatable, non-magnetic.

- 5052 Aluminum: Easily weldable, exceptionally corrosion-resistant, formable, heat treatable, non-magnetic.

- 6063 Aluminum: Known for high corrosion resistance and formability, used in structural applications, heat treatable, non-magnetic.

- MIC6 Aluminum: Stress-relieved cast aluminum, great for tight tolerance applications, non-magnetic, not heat treatable.

Our CNC Aluminum Machining Service

At GCH Process, we provide comprehensive CNC aluminum machining services, including CNC milling, CNC turning, EDM, and anodizing surface treatment, to create custom-designed parts with high precision based on your mechanical engineering drawings.

Our services are designed to help global customers streamline their operations and manage custom parts efficiently. Our experienced engineers work to reduce labor and machining costs by automating repetitive tasks, improving profit margins, and saving lead time.

We cater to both large volume orders and small batches, with no MOQ and delivery starting from 3 days.

What Aluminum Grade Should Be Used?

- Aluminum 2024: Known for high hardness, primarily used in aviation.

- Aluminum 5052: Features low density, high tensile strength, and high elongation, suitable for bending and welding.

- Aluminum 6061: Contains magnesium and silicon, combining the advantages of 4000 and 5000 series aluminum, suitable for high corrosion and oxidation resistance applications.

- Aluminum 6063: Commonly used as an architectural alloy for industrial structural parts requiring high strength and corrosion resistance.

- Aluminum 7075: Known as “super hard aluminum,” ideal for highly stressed parts in aerospace and manufacturing high-stress structures.

Types of CNC Machining Aluminum Processes

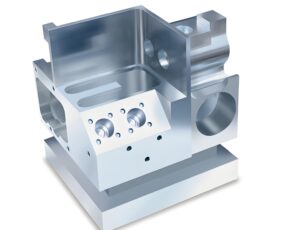

At GCH Process, we utilize various CNC aluminum machining processes to produce fully-finished products in diverse shapes and sizes:

- External CNCs: Used for processes requiring close tolerances or high speed.

- Internal CNCs: Feature an offset tooling system allowing for more complex features like blind holes and screw bosses.

- 3/4/5-axis machines: Offer advanced capabilities with horizontal and vertical spindle axes for complex workpieces with multiple geometries.

Cost of CNC Aluminum Machining

The cost of aluminum machining depends on material, product size, complexity, and machine selection.

- Material Costs: Aluminum 6061 costs $25 per block, Aluminum 7075 costs $80 per block.

- Labor Costs: $20 per hour for 3-axis machining, $30 per hour for 4-axis, $50 per hour for 5-axis.

Alternatives to Aluminum Material for CNC Machining

- Steel & Stainless Steel: Offer higher strength and temperature resistance.

- Titanium: Provides an exceptional strength-to-weight ratio, though more costly.

- Brass: Suitable for aesthetic applications, albeit at a higher cost.

- Copper: Offers superior electrical conductivity, though less machinable than aluminum.

Conclusion

CNC precision machining is crucial for manufacturing high-accuracy components across various industries. GCH Process provides expert, cost-effective CNC machining services, ensuring we meet the diverse needs of our clients with advanced capabilities, extensive material options, and a commitment to quality.

Contact GCH Process Today

Transform your designs into reality with our high-precision CNC aluminum machining services. Get in touch with us to discuss your project requirements and receive a detailed quote.