Custom Sheet Metal Fabrication Services

Get a free quote for custom sheet metal prototypes and low-volume production parts. Precision quality with 3-day lead time.

- Free quotation with DFM review in 12 hours

- Lead time as fast as 3 days

- ISO 9001:2015 certificated

10 S

Instant Quotes

1 day

Lead time

0 pc

MOQ

0.01 mm

Tolerances

Our Custom Injection Molding Services

With GCH’s injection molding solutions, we tailor parts to exact size, complexity, and volume specifications. Our machinery, ranging from 30 tons to 1800 tons, enables on-demand prototyping and production runs, guaranteeing design precision. Each injection molding order comes with a complimentary design consultation, enhancing product competitiveness. Expect rapid turnarounds with lead times as short as 15 days.

القطع بالليزر

Laser cutting is a technology that directs a high-power laser to cut sheet metals, offering precision, fast processing, and the ability to create intricate designs with smooth finishes and tight tolerances.

القطع بالبلازما

Plasma cutting is a process that cuts through electrically conductive materials using an accelerated jet of hot plasma. Ideal for thick materials, it offers high speed, low cost, and efficiency for large-scale industrial metal fabrication.

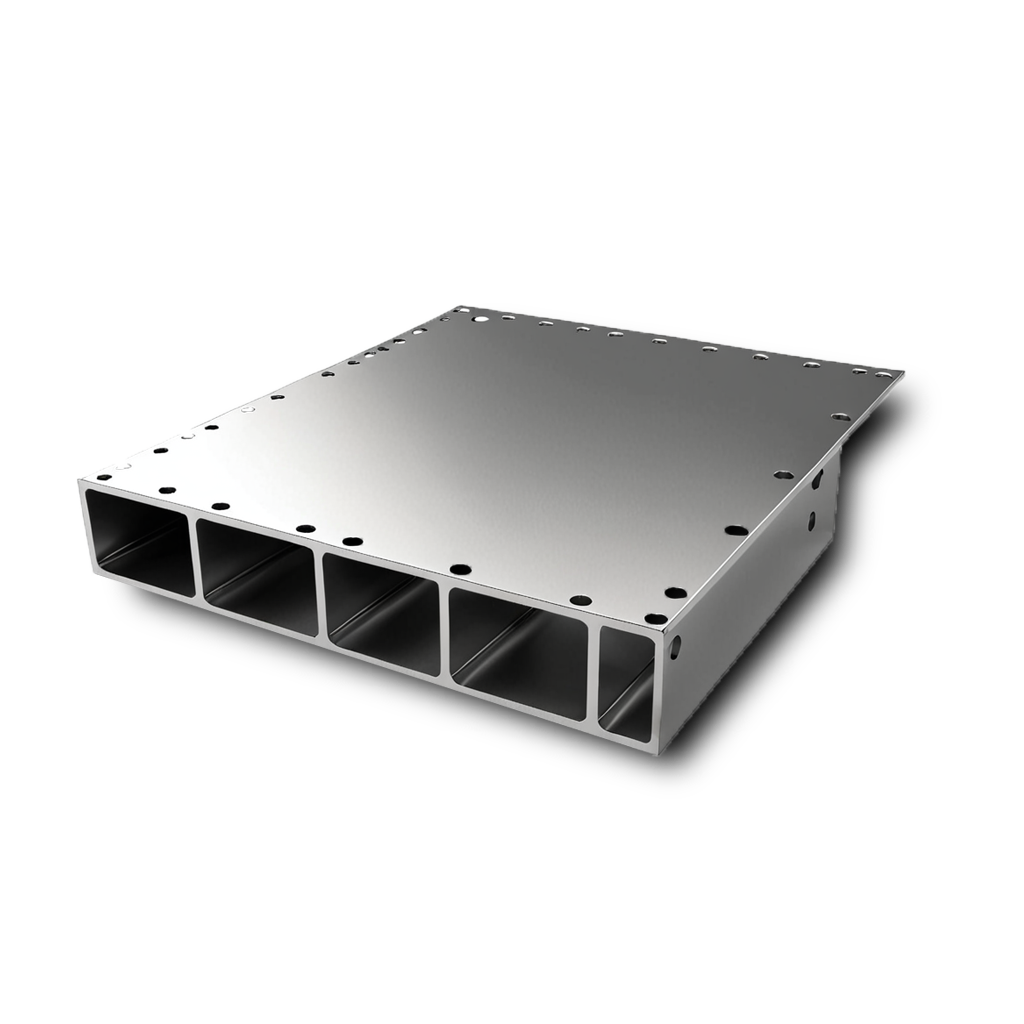

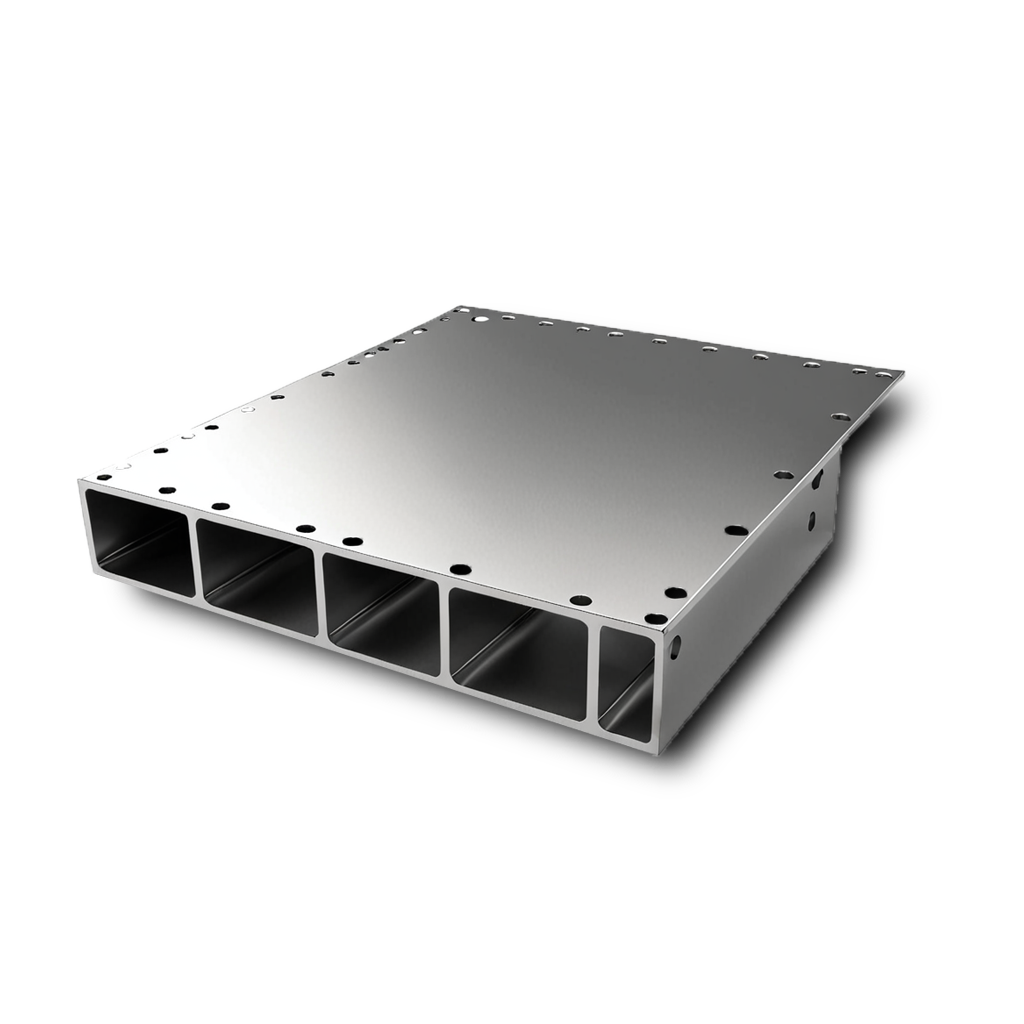

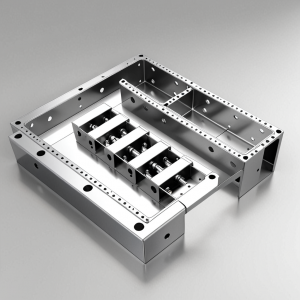

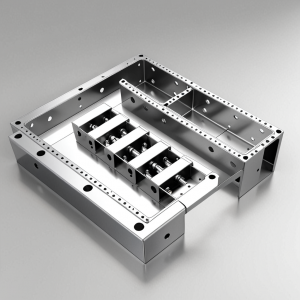

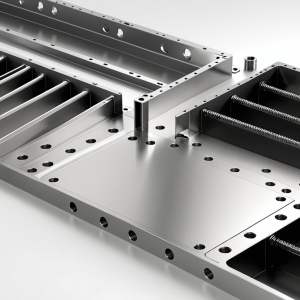

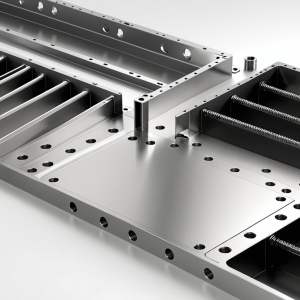

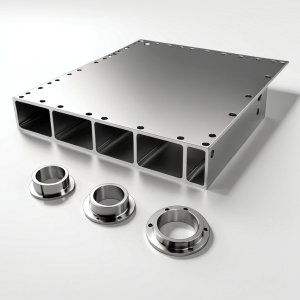

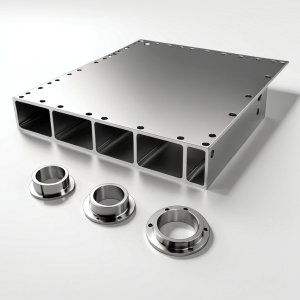

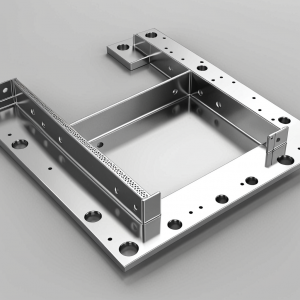

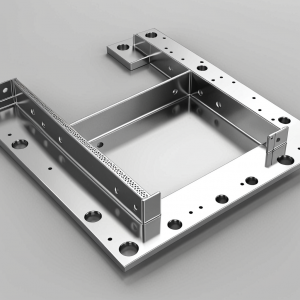

Sheet Metal Parts Made by GCH

View custom flat and formed sheet metal prototypes and production parts, from durable brackets to complicate panels, all produced with precision for diverse industry needs.

Custom Injection Molding Solutions

Explore our on-demand injection molding solutions to seamlessly transition from prototyping to high-quality production.

النماذج الأولية السريعة

Benefit from our rapid injection molding, delivering 1K-100K units quickly at a low cost. Using aluminum or steel molds, we ensure fast turnaround, directly addressing your production challenges and reducing time-to-market.

Low Volume Production

Low volume injection molding elevates your output, delivering 100K-1M units using resilient steel molds. This ensures high quality and consistency, effectively addressing your need for sizable yet precise production runs while maintaining exceptional standards.

Sheet Metal Fabrication Materials

Our selection of sheet metal materials includes aluminum, brass, stainless steel, and copper, each enhancing the durability and aesthetics of your metal components.

ألومنيوم

Aluminum with its lightweight yet robust nature, offers enhanced durability without excess weight. Its superior malleability allows precise shaping, ideal for intricate designs.

AL5052

AL5083

AL6061

AL6063

النحاس

Copper’s advantages are clear: unparalleled electrical conductivity, thermal efficiency, and natural resistance to corrosion, ensuring longevity and performance in fabrications.

CU1020

CU1100

CU2100

CU2200

CU2300

CU2400

CU2600

Brass

Opt for brass to ensure precise machining, a distinct appearance, and efficient heat conductivity, providing advantages for both practical and decorative applications.

C27400

C28000

Brass

With its robustness, versatility, and recyclability, steel is an excellent material choice, ensuring long-lasting performance and environmental sustainability.

Cold Rolled Steel Plate (SPCC)

Hot Rolled Steel Plate (SPHC)

Electrolytic Plate (SECC)

Galvanized Plate (SGCC)

الفولاذ المقاوم للصدأ

Renowned for its durability and resistance to staining, stainless steel ensures longevity and maintains its appearance, even in harsh environments.

301 303 304 316 420 430

Sheet Metal Fabrication Surface Finishing

Select from our various sheet metal finishes to enhance corrosion resistance, durability, and visual appeal. For finishes not listed on our quote page, simply select ‘Other’ and specify your requirements for a customized solution.

| الاسم | المواد | اللون | الملمس | السُمك | |

| الطلاء بأكسيد الألومنيوم | ألومنيوم | شفاف، وأسود، ورمادي، وأحمر، وأزرق، وذهبي. | لمسة نهائية ناعمة وغير لامعة. | طبقة رقيقة 5-20 ميكرومتر طبقة أكسيد الأنوديك الصلبة: 60-200 ميكرومتر |

| تفجير البيد | ABS، والألومنيوم، والنحاس، والفولاذ المقاوم للصدأ، والفولاذ | غير متاح | ماتي | 0.3 مم - 6 مم |

| طلاء المسحوق | ألومنيوم، ستانلس ستيل، فولاذ مقاوم للصدأ، فولاذ | أسود، أي كود RAL أو رقم بانتون | لامع أو شبه لامع | 5052 ألومنيوم 5052 0.063″-0.500" 6061 ألومنيوم 6061 0.063″ -0.500" ألومنيوم 7075 ألومنيوم 0.125″ -0.250″ فولاذ طري 0.048″-0.500" 4130 فولاذ كرومولي 4130 0.050″-0.250" فولاذ مقاوم للصدأ 0.048″-0.500" |

| الطلاء الكهربائي | ألومنيوم، فولاذ، فولاذ مقاوم للصدأ | غير متاح | لمسة نهائية لامعة وناعمة | 30-500 ميكروغرام |

| التلميع | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | غير متاح | لامع | غير متاح |

| التنظيف بالفرشاة | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | ساتان | غير متاح |

| الطباعة بالشاشة الحريرية | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | غير متاح | < 1 ميكرومتر |

| التخميل | الفولاذ المقاوم للصدأ | لا يوجد | لم يتغير | 5 ميكرومتر - 25 ميكرومتر |

General Tolerances for Sheet Metal Fabrication

Our sheet metal shops follow ISO 13485 tolerances to deliver consistent quality. For tolerances beyond these standards, detail your needs on the design schematics or reach out to our engineers.

| Dimension Detail | Metric Units | Imperial Units |

| Edge to edge, single surface | +/- 0.127 mm | +/- 0.005 in. |

| Edge to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

| Hole to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

| Bend to edge / hole, single surface | +/- 0.254 mm | +/- 0.010 in. |

| Edge to feature, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

| Over formed part, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

| Bend angle | +/- 1° |

How Custom Sheet material fabrication work?

The Sheet material fabrication process involves feeding raw plastic materials into an Sheet material fabrication machine, melting them down, and then fabrication them into an aluminum or steel mold. Upon cooling, a production-grade thermoplastic part is formed and ejected for further use or assembly.

Sheet Fabrication Process At GCH

Our Sheet Metal Fabrication for Various Applications

With custom sheet metal, GCH supports diverse industry requirements.

The FAQ

Frequently Asked Questions

GCH offers a comprehensive range of services including cutting, bending, punching, welding, and assembling. Our state-of-the-art machinery ensures precision and high-quality finishes for all projects.

Sheet metal fabrication tolerances refer to the acceptable deviations for features of sheet metal parts required for accurate and consistent installation and integration.

For sheet metal parts, ISO 2768-mk is usually used to ensure proper control of the elements of geometry and size. The following will show you 7 tolerance standards range of linear and angular dimensions, flatness & straightness, cylindricity, and circularity.

K factor is the sheet metal process is the ratio of neutral axis to material thickness. This value changes with respect to the various physical properties and thickness of materials used.

Every aspect of a sheet metal fabrication project comes with an associated cost — the design, possible prototype, finishing processes, and others. Asides from the process itself, materials also cost money. To learn some tips for reducing custom sheet metal fabrication costs, you can learn from this article.

GHC accommodates both small and large production runs, from single prototypes to mass production, with no strict minimum order quantity.

Yes, GCH offers rapid prototyping services. This allows you to test and verify your design before committing to large-scale production.

Latest Posts

دور الأتمتة في التصنيع عالي الدقة

يضمن التصنيع عالي الدقة الدقة في إنتاج مكونات معقدة، باستخدام تكنولوجيا متقدمة لصناعات مثل الطيران والسيارات والأجهزة الطبية.

دور التصنيع باستخدام الحاسب الآلي في صناعة السيارات الحديثة

قطع غيار دقيقة للتصنيع الآلي باستخدام الحاسب الآلي للسيارات عالية الأداء. خدمات تصنيع مخصصة للنماذج الأولية والإنتاج.

تقدم معالجة الألومنيوم بنظام التحكم الرقمي للألومنيوم خدمات تصنيع آلي عالية الدقة لقطع الألومنيوم المخصصة، وهي مثالية للتطبيقات الصناعية.

تقدم معالجة الألومنيوم بنظام التحكم الرقمي للألومنيوم خدمات تصنيع آلي عالية الدقة لقطع الألومنيوم المخصصة، وهي مثالية للتطبيقات الصناعية.