Your Trusted Customization Partner in Medical Devices

Medical Devices Industry

GCH Precision Prototyping and On-Demand Production Advancing Medical Devices for Health and Well-Being

- Masterful craftsmanship in medical device components

- حاصلة على شهادة الأيزو 9001:2015

- دعم هندسي على مدار 24/7

- الصفحة الرئيسية

- Medical Devices Industry

لماذا تختارنا

GCH is not just a manufacturer; we are the catalyst for advancement in the medical device industry. Our team of experts harnesses cutting-edge technology, combining flexible customization strategies with a dedication to excellence in craftsmanship, to deliver optimal solutions for every medical device project.

البراعة التقنية

Our ISO 9001:2015 certification is a testament to our commitment to quality. We produce medical device components using the most suitable materials and advanced techniques, including precision machining, injection molding, and surface finishing.

عروض الخدمات المخصصة حسب الطلب

Whether it’s creating prototypes for design validation or scaling up to production runs for market deployment, GCH provides fully tailored services. Our mission is to transform your medical device visions into tangible realities.

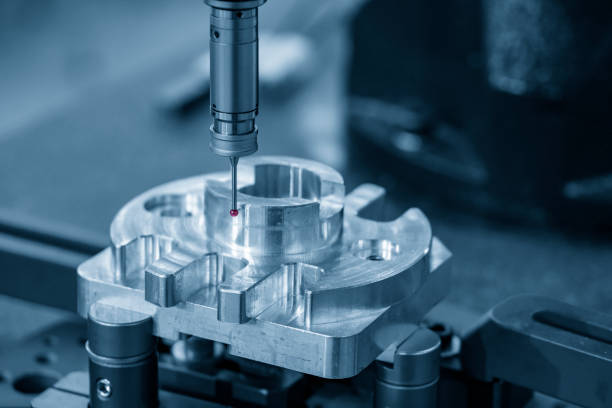

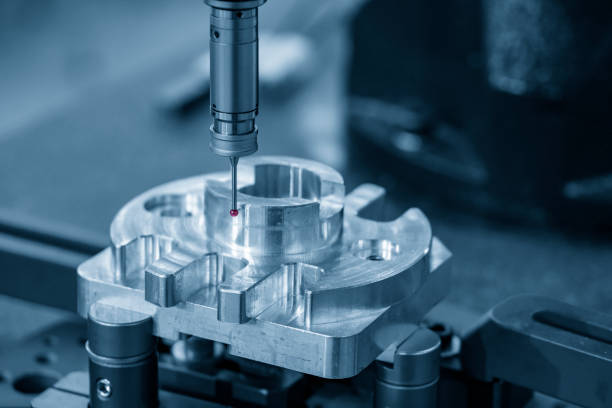

تصنيع المكونات الدقيقة

We understand the stringent requirements of the medical device industry for precision parts. Our manufacturing capabilities are engineered to satisfy the most stringent tolerance specifications, ensuring the seamless operation and superior performance of your medical device components.

ضمان الجودة والتحسين المستمر

التزامنا بالجودة لا يتزعزع. فمن خلال تنفيذ تدابير صارمة لمراقبة الجودة واستخدام تقنيات الفحص المتقدمة، نضمن أن منتجاتك لا تلبي التوقعات فحسب، بل تتجاوزها.

موثوق بها من قبل شركات فورتشن 500

Our partners include leading medical device manufacturers who trust in our innovation and reliability. We foster intimate collaborations with our clients to deliver personalized solutions for every medical device project.

- Surgical equipment developers

- Diagnostic device innovators

- Medical imaging specialists

- Research and educational institutions in medical technology

- Suppliers of medical device components and assemblies

- Experts in biocompatibility and regulatory compliance

Manufacturing Capabilities for Medical Device Components

Our rapid prototyping and on-demand production services are designed for businesses looking to lead in the dynamic medical device market. Our comprehensive capabilities encompass material science expertise, precise process control, high-quality production, and a robust quality management system.

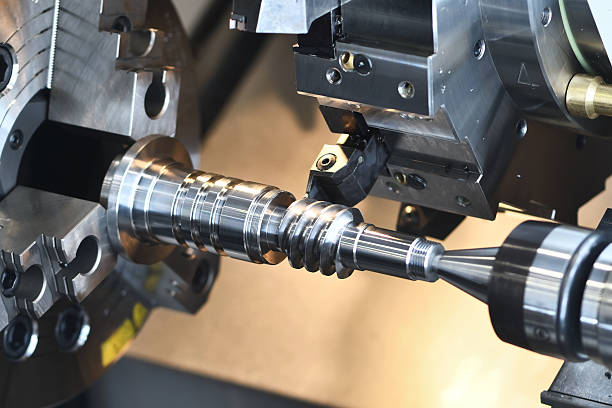

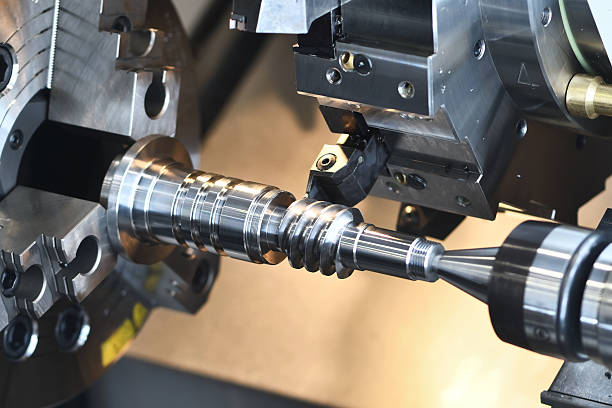

التصنيع الآلي باستخدام الحاسب الآلي

التصنيع الآلي السريع والدقيق باستخدام ماكينات بنظام التحكم الرقمي من خلال استخدام أحدث المعدات والمخارط ثلاثية المحاور وخماسية المحاور.

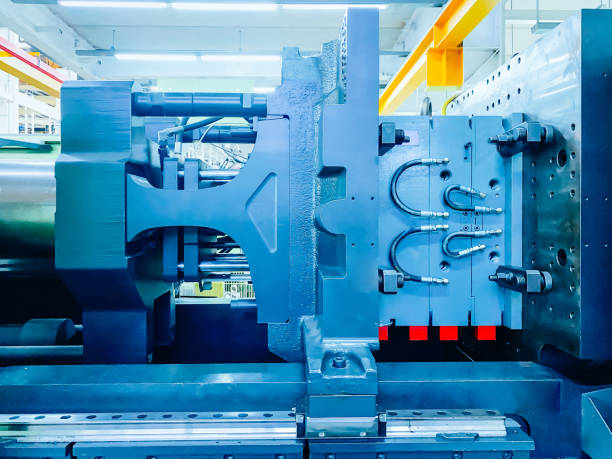

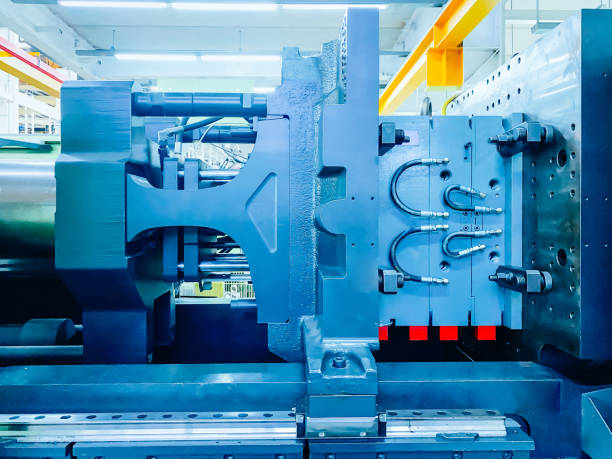

القولبة بالحقن

خدمة القولبة بالحقن حسب الطلب لتصنيع النماذج الأولية البلاستيكية عالية الجودة وبأسعار تنافسية وقطع الإنتاج البلاستيكية عالية الجودة في وقت سريع.

تصنيع الصفائح المعدنية

من مجموعة متنوعة من أدوات القطع إلى معدات التصنيع المختلفة، يمكننا إنتاج كميات كبيرة من الصفائح المعدنية المصنعة.

الصب بالليزر

تضمن لنا خبرتنا في مجال الصب بالتفريغ سرعة إنتاج النماذج الأولية للأجزاء البلاستيكية المصنوعة من البلاستيك المرن ذات التصميمات المعقدة والمفصلة للغاية.

التطبيقات

GCH’s medical device components perform exceptionally well in a wide range of applications, demonstrating exceptional performance and resilience, including surgical instruments, diagnostic equipment, medical imaging devices, and patient monitoring systems.

- Handheld devices

- Surgical instruments

- Medical testing devices

- Ventilators

- Implantable prototypes

- UV sanitation components

Custom Prototypes and Parts for the Medical Device Industry

Our seasoned team boasts unparalleled expertise in the manufacturing of custom prototypes and parts for the medical device industry. From design to delivery, we ensure that every product meets your high standards.