أدوات حقن القوالب بالحقن

Reliable injection mold tooling creation for custom injection molded parts. Get precise and outstanding custom injection molds to produce high-quality plastic parts. Take advantage of our commitment to quality, quick production, and competitive pricing.

- Tight Tolerance of 0.02 mm

- Professional DFM Report

- Free Mold Flow Analysis

- الصفحة الرئيسية

- أدوات حقن القوالب بالحقن

Build Perfect Molds for Better Production Parts

Get your injection molded parts created in the most innovative way. At GCH, we offer custom injection molds that guarantee the success of your projects. We work with you to understand the peculiarities of your project, then develop a precise plastic injection mold design according to your specifications. Our expert technicians handle all complexities involved in the mold production process.

Our versatility allows us to develop prototype tools and production molds at affordable prices. With the fastest possible lead times, our capabilities help us optimize production and get your products to market faster. Are you ready to take plastic part production to the highest level? GCH is ready to assist you in that journey.

Why Choose Us for Injection Mold Tooling

GCH applies strict quality standards to every plastic injection mold, ensuring consistency and quality for molded components. Our experts work with you from prototyping through production to optimize rapid tooling for prototypes and production parts. Every step of our mold production showcases our commitment to quality and customer satisfaction.

No MOQ

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced injection molding cost.

Tight Tolerance and High Quality

Our plastic injection molding process includes vital design considerations to improve moldability and enhance aesthetic appearance. GCH delivers plastic injection molded parts of varying sizes and complexities. Our standard tolerances are defined by ISO 2768 standards, helping us meet tight tolerance requirements.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Injection Molding Specialists

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

Injection Mold Tooling Processes At GCH

Materials for Injection Mold Tooling

The material used for mold tooling determines its life span and the quality of injection molded parts. We offer multiple grades of materials for injection molds used in different stages of product development. Our professionals select suitable materials to achieve varying levels of dimensional precision and aesthetic quality. We also provide professional advice on mold materials.

Tool Steel

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include tool steel.

Types: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

الفولاذ المقاوم للصدأ

Injection molds were created from steel and stainless steel which are expensive to manufacture. They are typically only used in large-scale productions.

Types:

420, NAK80, S136, 316L, 316, 301, 303, 304

ألومنيوم

Aluminum molds cost substantially less than traditional steel and carbon steel injection molds. Aluminum molds offer faster cycles and quick turnaround to help test markets.

Types: 6061, 5052, 7075

Surface Finishes for Plastic Injection Molding

Improve the surface quality of your plastic injection molded parts with superior surface finishing options. GCH provides an extensive list of surface treatments to improve the aesthetic appeal of your products. These efficient secondary operations also improve the mechanical qualities of prototypes and production parts.

How Custom Injection Molding Works?

The injection molding process involves feeding raw plastic materials into an injection molding machine, melting them down, and then injecting them into an aluminum or steel mold. Upon cooling, a production-grade thermoplastic part is formed and ejected for further use or assembly.

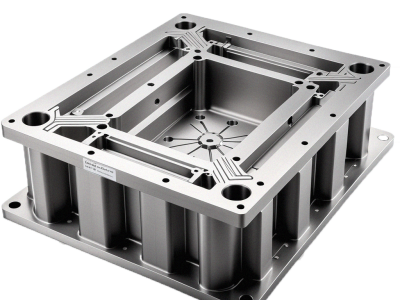

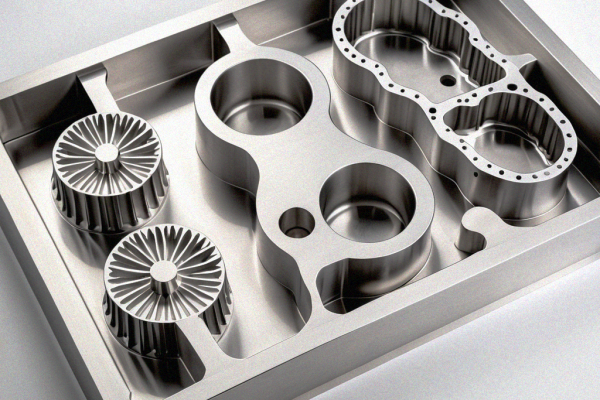

Gallery of Plastic Injection Molded Parts

Dive into GCH’s extensive gallery that showcases some of our completed injection molded parts and take confidence that we can create your injection molding project according to your strict specifications.

The FAQ

Frequently Asked Questions

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Tolerances are crucial in injection molding; without proper specification and control, assembly issues can arise. At GCH, we adhere to the ISO 2068-c standard for molding tolerances, but can accommodate tighter specifications if needed.

We have no minimum order requirement. However, larger quantities will yield more competitive pricing.

Once an order is placed, mold design and creation typically take around 35 days, with an additional 3-5 days for the production of the molded parts.

The cost of our services varies based on several factors such as component size, mold complexity, number of cavities, material type, and post-processing requirements. We provide quotes after analyzing these factors on our platform.

At GCH, we offer a wide range of thermoplastic and thermosetting materials suitable for various applications. Some common materials include ABS, Polycarbonate, Polypropylene, and TPE. For a full list of materials or custom material requests, please contact our customer service.

Yes, GCH offers rapid prototyping services. This allows you to test and verify your design before committing to large-scale production.

Latest Posts

The Challenges Of Titanium CNC Machining And How To Overcome Them

Expert Titanium CNC Machining – Precision CNC machining of titanium parts for aerospace, medical, and industrial applications. High-quality custom parts manufacturing.

Top Challenges in Machining Titanium Alloys and How to Overcome Them

Titanium alloy machining: Expert precision manufacturing for aerospace, medical, and industrial applications.

دور الأتمتة في التصنيع عالي الدقة

يضمن التصنيع عالي الدقة الدقة في إنتاج مكونات معقدة، باستخدام تكنولوجيا متقدمة لصناعات مثل الطيران والسيارات والأجهزة الطبية.