نماذج GCH الأولية والإنتاج عند الطلب من أجل

صناعة السيارات

خدمات تصنيع النماذج الأولية المخصصة للسيارات وتصنيع قطع الغيار لتطوير منتجات السيارات. عمليات تصنيع مبسطة وأسعار تنافسية وإنتاج حسب الطلب.

- تفاوتات تصل إلى ± 0.0004″ (0.01 مم)

- حاصلة على شهادة الأيزو 9001:2015

- دعم هندسي على مدار 24/7

لماذا تختارنا

تستفيد GCH من تكنولوجيا الماكينات بنظام التحكم الرقمي المتقدمة، والحلول المخصصة، والعمليات الفعالة، والالتزام بالجودة لتقديم خدمات تصنيع آلي فائقة لصناعة السيارات.

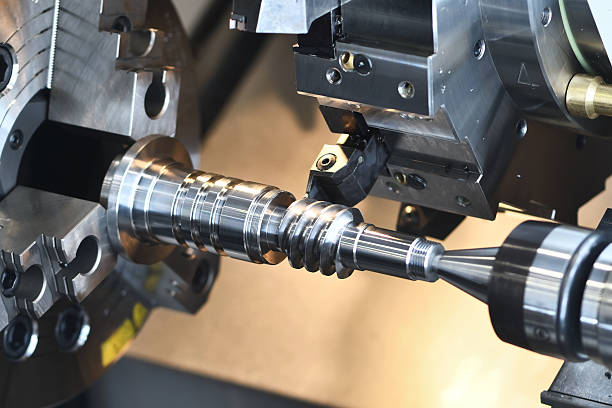

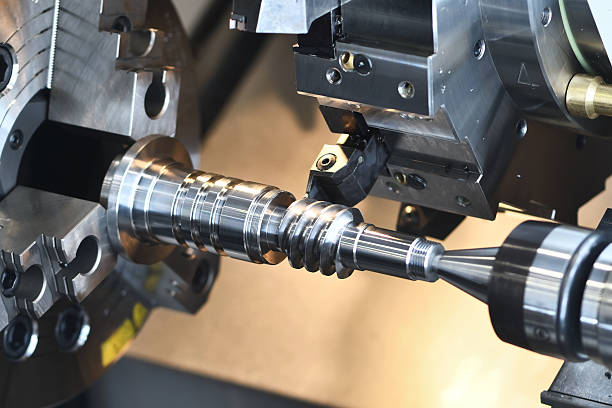

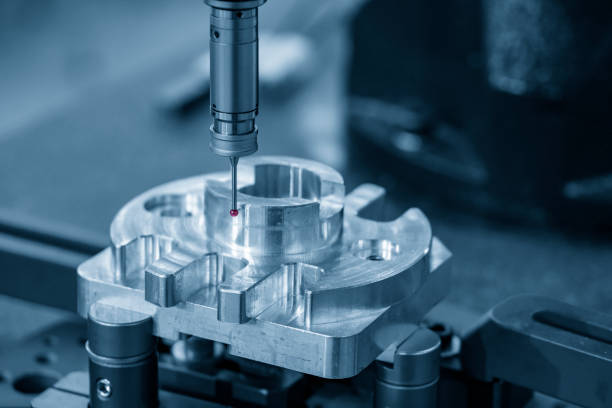

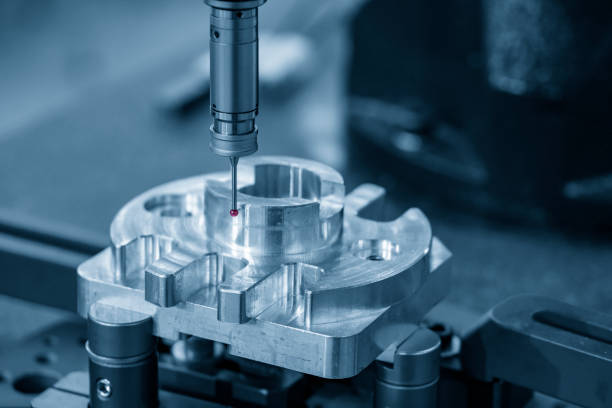

تكنولوجيا ومعدات التحكم الرقمي باستخدام الحاسب الآلي المتقدمة

تمتلك GCH التكنولوجيا الرائدة في مجال التصنيع باستخدام الحاسب الآلي ومعدات التصنيع الآلي الحديثة، القادرة على تلبية متطلبات الدقة والتعقيد العالية في صناعة السيارات. وهذا يضمن قدرتك على إنتاج قطع غيار السيارات التي تلبي معايير الجودة الصارمة.

حلول مخصصة حسب الطلب

تقدم GCH خدمات التصنيع الآلي باستخدام الحاسب الآلي المصممة خصيصًا لتلبية احتياجات عملائنا المحددة، سواءً للإنتاج على دفعات صغيرة أو التصنيع على نطاق واسع. توفر مرونتنا في تلبية المتطلبات الفردية حلولاً مخصصة لعملائنا.

الإدارة الفعالة للإنتاج ومراقبة التكاليف

لدينا قدرات فعالة في إدارة الإنتاج، وتحسين عملية الإنتاج، وتقليل المهل الزمنية للإنتاج، والتحكم الصارم في التكاليف لضمان أسعار تنافسية لعملائك.

المراقبة والتحسين المستمر للجودة

تعطي GCH الأولوية لمراقبة الجودة والتحسين المستمر، وتنفذ أنظمة صارمة لإدارة الجودة وتستخدم أدوات فحص الجودة المتقدمة لضمان أن كل منتج يلبي توقعات عملائك أو يفوقها.

مزود خدمات معالجة قطع غيار السيارات من الدرجة الأولى من الصين

مع سنوات عديدة من التركيز في صناعة الماكينات بنظام التحكم الرقمي، لم تكتسب GCH اعتراف غالبية مجموعات العملاء فحسب، بل هي أيضًا واحدة من الشركات المصنعة القليلة التي تمتلك IATF 16949-2016 الشهادات.

موثوق بها من قبل شركات فورتشن 500

- الشركات المصنعة للمعدات الأصلية للسيارات

- شركات تكنولوجيا السيارات

- السيارات الكهربائية

- المركبات التجارية

- المركبات الخدمية

- الدراجات والدراجات البخارية الكهربائية

قدرات تصنيع السيارات

استفد من خدمات التصنيع الاحترافية التي نقدمها طوال دورة الإنتاج، بدءاً من النماذج الأولية والتحقق من صحة التصميم إلى الاختبار الوظيفي وإطلاق المنتج. نحن نقدم قطع غيار سيارات عالية الجودة والدقة مع سرعة الإنجاز وبتكاليف منخفضة. وبفضل عملية مراقبة الجودة التي نتبعها، يمكنك التأكد من الحصول على قطع تلبي متطلباتك الفريدة.

التصنيع الآلي باستخدام الحاسب الآلي

التصنيع الآلي السريع والدقيق باستخدام ماكينات بنظام التحكم الرقمي من خلال استخدام أحدث المعدات والمخارط ثلاثية المحاور وخماسية المحاور.

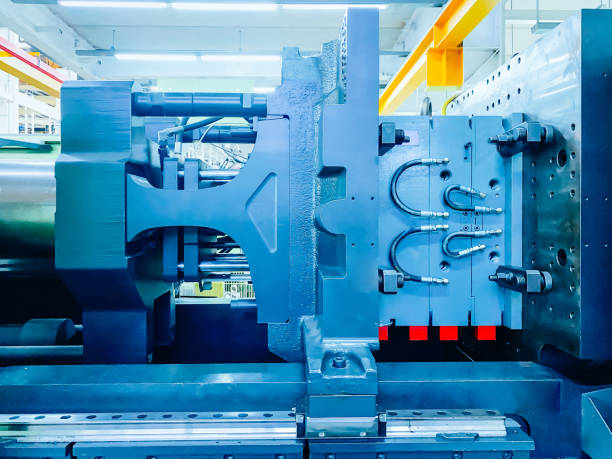

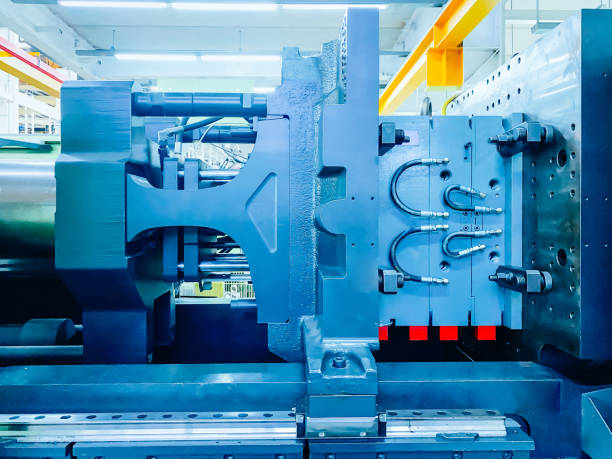

القولبة بالحقن

خدمة القولبة بالحقن حسب الطلب لتصنيع النماذج الأولية البلاستيكية عالية الجودة وبأسعار تنافسية وقطع الإنتاج البلاستيكية عالية الجودة في وقت سريع.

تصنيع الصفائح المعدنية

من مجموعة متنوعة من أدوات القطع إلى معدات التصنيع المختلفة، يمكننا إنتاج كميات كبيرة من الصفائح المعدنية المصنعة.

الصب بالليزر

تضمن لنا خبرتنا في مجال الصب بالتفريغ سرعة إنتاج النماذج الأولية للأجزاء البلاستيكية المصنوعة من البلاستيك المرن ذات التصميمات المعقدة والمفصلة للغاية.

مواد لمكونات السيارات

اعتمادًا على متطلبات قطع الطيران الخاصة بك، تتوافق عمليات التصنيع الآلي لدينا مع مجموعة كبيرة من المواد. لدينا قائمة طويلة من المواد المعدنية والمركبة من فئة الإنتاج التي تلبي متطلبات صناعة الطيران. اطلع على بعض المواد شائعة الاستخدام لمكونات صناعة الطيران.

ألومنيوم

يتميز الألومنيوم بنسبة قوة إلى وزن ممتازة لهذا المعدن. وهو خيار رائع لمتطلبات التحميل العالية لأقواس ومبيتات الطائرات. يتميز الألومنيوم أيضاً بليونة جيدة، وصلابة، ومقاومة للتآكل، وقابلية التشغيل الآلي. كما أن خواصه خفيفة الوزن تجعله مفيداً للتطبيقات الهيكلية للطائرات مثل جلد جسم الطائرة، وأوتار الأجنحة، وجلود الأجنحة، وما إلى ذلك.

السعر: $

المهلة الزمنية: < أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

تيتانيوم

يتميّز التيتانيوم بعدد من الخصائص المادية التي تجعله المعدن المثالي للتطبيقات الصعبة. وتشمل هذه الخصائص مقاومة ممتازة للتآكل والمواد الكيميائية ودرجات الحرارة القصوى. كما يتمتع المعدن بنسبة قوة إلى وزن ممتازة.

تجعل هذه الخصائص من سبائك التيتانيوم خيارات رائعة لهياكل الطائرات ومحركات الطائرات.

السعر: $$$

المهلة الزمنية: < أقل من 10 أيام

سُمك الجدار: 0.75 مم

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

الفولاذ المقاوم للصدأ

الصلب هو معدن آخر يستخدم في إنتاج قطع غيار السيارات الحديثة. هذا المعدن متين وفعال في الأداء. كما أنه يسهل إنتاج أجزاء عالية الجودة. كما أنه مقاوم للتآكل وخفيف الوزن ويؤدي إلى إنتاج أجزاء مبهجة من الناحية الجمالية. يستخدم هذا المعدن في إنتاج مكابح السيارات، والمحركات، وأنظمة العادم، والعجلات، وغيرها.

السعر: $

المهلة الزمنية: < أقل من 10 أيام

سُمك الجدار: 0.75 مم

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

النحاس

يلعب النحاس دوراً كبيراً في الراحة والكفاءة والسلامة في صناعة السيارات. إنه موصل ممتاز للكهرباء ومطاطي للغاية وقابل للطرق. وله استخدامات في معظم المكونات الإلكترونية للسيارة، بما في ذلك الأسلاك الخاصة بالسيارة، والمبرد، ومحرك بدء التشغيل، ومولد الكهرباء، ومولد التيار المتردد، وأنابيب المكابح.

السعر: $

المهلة الزمنية: <أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

المغنيسيوم

يتميز المغنيسيوم بخفة وزنه وقابليته الممتازة للصب وقوته النوعية العالية، مما يتيح له استخدامات في صناعة السيارات. ويستخدم المغنيسيوم في إنتاج كتل المحركات، وعلب التروس، وعلب التروس، وعلب القابض، والعجلات، وحوامل المحركات، وأحواض الزيت.

السعر: $

المهلة الزمنية: <أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

اللدائن الحرارية

تتميز هذه اللدائن الحرارية بخصائص ممتازة تتراوح بين مقاومة الصدمات العالية والقدرة على مقاومة درجات الحرارة العالية. PPS. على سبيل المثال، تتمتع بثبات أبعاد ممتاز، وتحمل درجات الحرارة ومقاومة الصلابة. يمكنك العثور على اللدائن الحرارية في الأجزاء الداخلية للمركبات، بالإضافة إلى إطارات البطاريات ومصدات المركبات.

التشطيب السطحي لقطع غيار السيارات

احصل على تشطيبات سطحية عالية الجودة لمكوناتك الفضائية لتحسين الصفات الجمالية لمنتجاتك. تعمل خدمات التشطيب الفائقة التي نقدمها أيضًا على تحسين مقاومة هذه الأجزاء للتآكل والتآكل مع تحسين خصائصها الميكانيكية.

| الاسم | المواد | اللون | الملمس | السُمك | |

| الطلاء بأكسيد الألومنيوم | ألومنيوم | شفاف، وأسود، ورمادي، وأحمر، وأزرق، وذهبي. | لمسة نهائية ناعمة وغير لامعة. | طبقة رقيقة 5-20 ميكرومتر طبقة أكسيد الأنوديك الصلبة: 60-200 ميكرومتر |

| تفجير البيد | ABS، والألومنيوم، والنحاس، والفولاذ المقاوم للصدأ، والفولاذ | غير متاح | ماتي | 0.3 مم - 6 مم |

| طلاء المسحوق | ألومنيوم، ستانلس ستيل، فولاذ مقاوم للصدأ، فولاذ | أسود، أي كود RAL أو رقم بانتون | لامع أو شبه لامع | 5052 ألومنيوم 5052 0.063″-0.500" 6061 ألومنيوم 6061 0.063″ -0.500" ألومنيوم 7075 ألومنيوم 0.125″ -0.250″ فولاذ طري 0.048″-0.500" 4130 فولاذ كرومولي 4130 0.050″-0.250" فولاذ مقاوم للصدأ 0.048″-0.500" |

| الطلاء الكهربائي | ألومنيوم، فولاذ، فولاذ مقاوم للصدأ | غير متاح | لمسة نهائية لامعة وناعمة | 30-500 ميكروغرام |

| التلميع | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | غير متاح | لامع | غير متاح |

| التنظيف بالفرشاة | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | ساتان | غير متاح |

| الطباعة بالشاشة الحريرية | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | غير متاح | < 1 ميكرومتر |

| التخميل | الفولاذ المقاوم للصدأ | لا يوجد | لم يتغير | 5 ميكرومتر - 25 ميكرومتر |

تطبيقات السيارات

تساعد قدراتنا التصنيعية في تسريع إنتاج مجموعة واسعة من المكونات الفضائية للتطبيقات الفريدة. فيما يلي بعض التطبيقات الشائعة في مجال الطيران:

- الأدوات السريعة، والأقواس، والهياكل، والرقصات السريعة

- المبادلات الحرارية

- التركيبات المخصصة

- قنوات التبريد المطابقة

- المضخات التوربينية والمشعبات

- مقاييس فحص الملاءمة

- فوهات الوقود

- مكونات تدفق الغاز والسائل