Custom Online CNC Machining Services

From prototypes to on-demand production parts, get an instant quote for your metal or plastic projects with our online CNC machining services. Choose from 40+ materials, 10+ surface finishes. ISO 9001:2015, ISO 13485 certified.

- Instant CNC quotes & detailed DFM

- Tolerances down to 0.01mm (±0.0004″ )

- Machined parts as fast as 1 day

10 S

Instant Quotes

1 day

Lead time

0 pc

MOQ

0.01 mm

Tolerances

Our CNC Machining Services

For engineers, product developers, and designers requiring prototyping and low-volume production, GCH’s custom CNC machining services are the solution. Whether your project involves simple or intricate designs with tight tolerances, our ISO 9001 certified CNC machine shops ensure excellence. Our rapid CNC machining capabilities promise high-quality custom machined parts delivered within just one day.

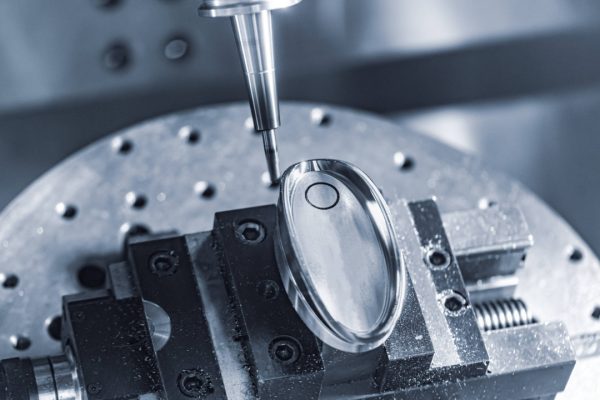

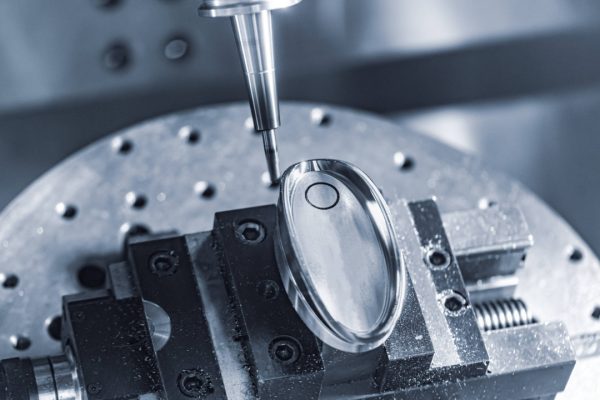

Custom CNC Milling Services

we offer Custom CNC Milling Services tailored to meet the specific requirements of industries such as aerospace, automotive, medical, and consumer goods. With our state-of-the-art CNC milling machines, we provide precise and complex milling operations that deliver exceptional quality, accuracy, and consistency.

Custom CNC Turning Services

we specialize in providing Custom CNC Turning Services designed to meet the exacting standards of various industries, including automotive, aerospace, medical, and consumer goods. Our advanced CNC turning centers allow for precise and efficient production of custom components with complex geometries and tight tolerances.

خدمات التصنيع الآلي الدقيق

we provide industry-leading خدمات التصنيع الآلي الدقيق to meet the most demanding specifications across various industries, including aerospace, medical, automotive, and electronics. Our advanced machining capabilities ensure that every part we produce adheres to the highest standards of accuracy, with tolerances as tight as ±0.001 mm.

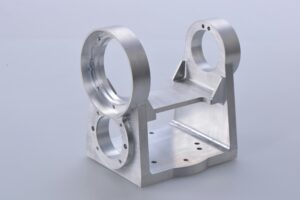

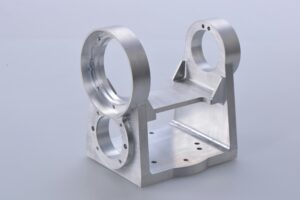

Gallery of CNC Machined Parts

View the custom CNC machined prototypes and end-use parts we’ve produced for our customers.

The core advantages of our CNC Machining services

Begin with a prototype, transition to small batches, and end with precise parts made just for your project. Every solution, designed for your needs.

Unmatched Expertise

With over a decade of experience in the CNC machining industry, GCH has developed a deep understanding of precision manufacturing. Our skilled team is equipped to tackle complex designs and deliver superior results, ensuring your project is in capable hands.

State-of-the-Art Technology

GCH utilizes advanced CNC machinery and cutting-edge technology to achieve high levels of accuracy and efficiency. Our commitment to innovation enables us to produce intricate parts with tight tolerances, enhancing the overall quality of your products.

Comprehensive Support

We offer end-to-end support throughout the machining process, from initial design consultation to final production. Our dedicated team collaborates closely with clients to ensure that every aspect of their project meets specifications and exceeds expectations.

CNC Machining Surface Finishes

From prototyping to production, GCH ensures superior quality and reliable functionality. With a wide selection of production-grade metal and plastic materials as well as highly advanced on-demand manufacturing techniques, we offer high-quality products across several industries.

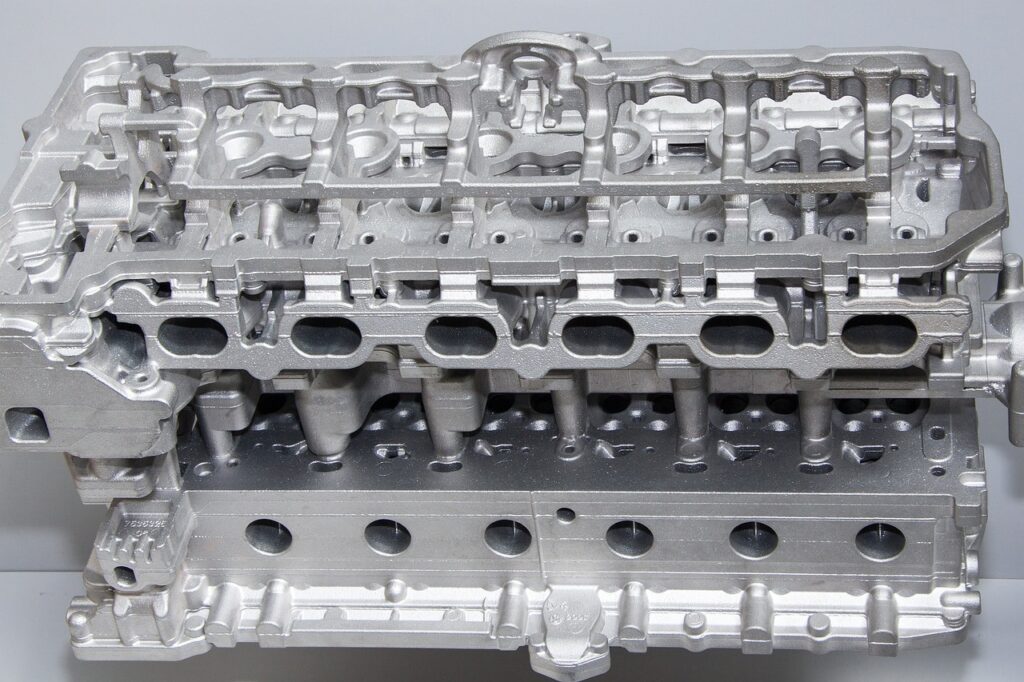

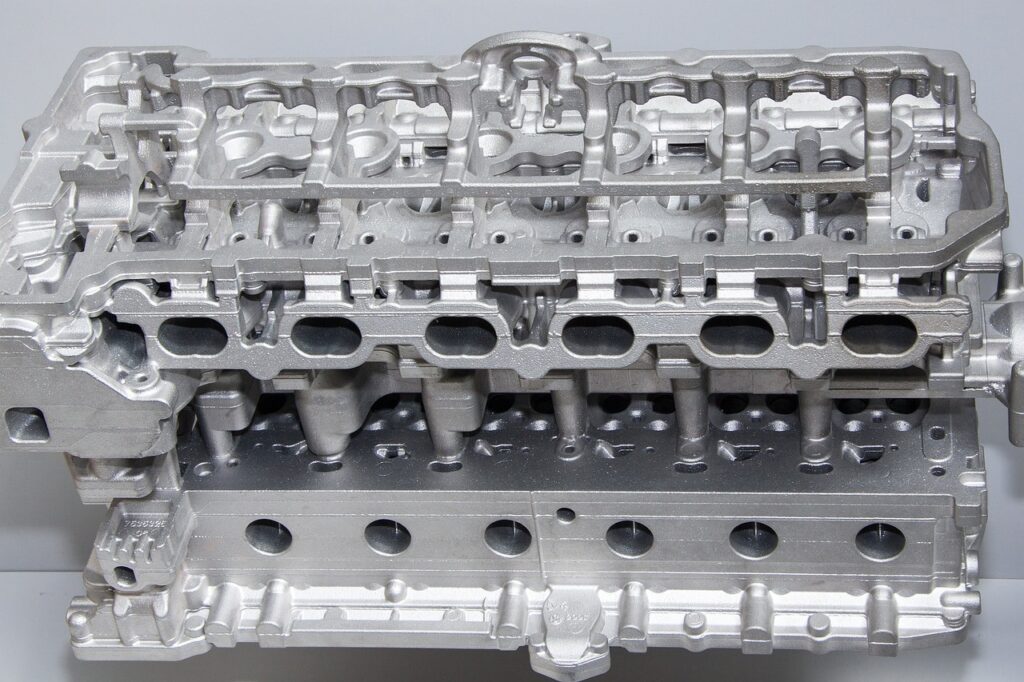

ألومنيوم

يتميز الألومنيوم بنسبة قوة إلى وزن ممتازة لهذا المعدن. وهو خيار رائع لمتطلبات التحميل العالية لأقواس ومبيتات الطائرات. يتميز الألومنيوم أيضاً بليونة جيدة، وصلابة، ومقاومة للتآكل، وقابلية التشغيل الآلي. كما أن خواصه خفيفة الوزن تجعله مفيداً للتطبيقات الهيكلية للطائرات مثل جلد جسم الطائرة، وأوتار الأجنحة، وجلود الأجنحة، وما إلى ذلك.

السعر: $

المهلة الزمنية: < أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

تيتانيوم

يتميّز التيتانيوم بعدد من الخصائص المادية التي تجعله المعدن المثالي للتطبيقات الصعبة. وتشمل هذه الخصائص مقاومة ممتازة للتآكل والمواد الكيميائية ودرجات الحرارة القصوى. كما يتمتع المعدن بنسبة قوة إلى وزن ممتازة.

تجعل هذه الخصائص من سبائك التيتانيوم خيارات رائعة لهياكل الطائرات ومحركات الطائرات.

السعر: $$$

المهلة الزمنية: < أقل من 10 أيام

سُمك الجدار: 0.75 مم

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

الفولاذ المقاوم للصدأ

الصلب هو معدن آخر يستخدم في إنتاج قطع غيار السيارات الحديثة. هذا المعدن متين وفعال في الأداء. كما أنه يسهل إنتاج أجزاء عالية الجودة. كما أنه مقاوم للتآكل وخفيف الوزن ويؤدي إلى إنتاج أجزاء مبهجة من الناحية الجمالية. يستخدم هذا المعدن في إنتاج مكابح السيارات، والمحركات، وأنظمة العادم، والعجلات، وغيرها.

السعر: $

المهلة الزمنية: < أقل من 10 أيام

سُمك الجدار: 0.75 مم

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

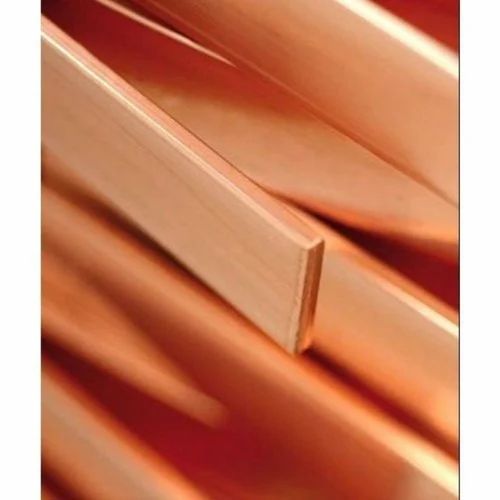

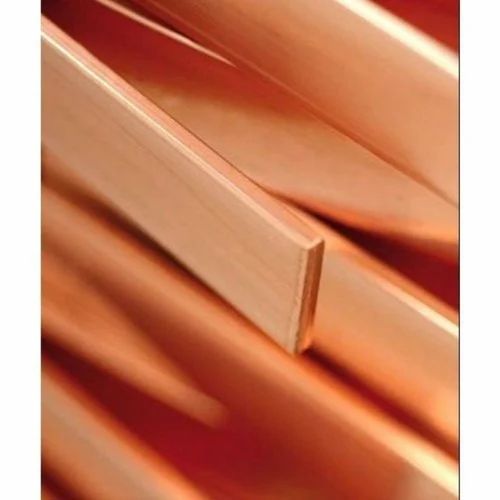

النحاس

يلعب النحاس دوراً كبيراً في الراحة والكفاءة والسلامة في صناعة السيارات. إنه موصل ممتاز للكهرباء ومطاطي للغاية وقابل للطرق. وله استخدامات في معظم المكونات الإلكترونية للسيارة، بما في ذلك الأسلاك الخاصة بالسيارة، والمبرد، ومحرك بدء التشغيل، ومولد الكهرباء، ومولد التيار المتردد، وأنابيب المكابح.

السعر: $

المهلة الزمنية: <أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

المغنيسيوم

يتميز المغنيسيوم بخفة وزنه وقابليته الممتازة للصب وقوته النوعية العالية، مما يتيح له استخدامات في صناعة السيارات. ويستخدم المغنيسيوم في إنتاج كتل المحركات، وعلب التروس، وعلب التروس، وعلب القابض، والعجلات، وحوامل المحركات، وأحواض الزيت.

السعر: $

المهلة الزمنية: <أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

Finishing Options for CNC machining

Improve the surface quality of your CNC machined parts with our superior surface finishing options. GCH offers an extensive range of surface treatments designed to enhance the aesthetic appeal of your products. These efficient secondary operations also improve the mechanical properties of both prototypes and production parts.

| الاسم | المواد | اللون | الملمس | السُمك | |

| الطلاء بأكسيد الألومنيوم | ألومنيوم | شفاف، وأسود، ورمادي، وأحمر، وأزرق، وذهبي. | لمسة نهائية ناعمة وغير لامعة. | طبقة رقيقة 5-20 ميكرومتر طبقة أكسيد الأنوديك الصلبة: 60-200 ميكرومتر |

| تفجير البيد | ABS، والألومنيوم، والنحاس، والفولاذ المقاوم للصدأ، والفولاذ | غير متاح | ماتي | 0.3 مم - 6 مم |

| طلاء المسحوق | ألومنيوم، ستانلس ستيل، فولاذ مقاوم للصدأ، فولاذ | أسود، أي كود RAL أو رقم بانتون | لامع أو شبه لامع | 5052 ألومنيوم 5052 0.063″-0.500" 6061 ألومنيوم 6061 0.063″ -0.500" ألومنيوم 7075 ألومنيوم 0.125″ -0.250″ فولاذ طري 0.048″-0.500" 4130 فولاذ كرومولي 4130 0.050″-0.250" فولاذ مقاوم للصدأ 0.048″-0.500" |

| الطلاء الكهربائي | ألومنيوم، فولاذ، فولاذ مقاوم للصدأ | غير متاح | لمسة نهائية لامعة وناعمة | 30-500 ميكروغرام |

| التلميع | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | غير متاح | لامع | غير متاح |

| التنظيف بالفرشاة | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | ساتان | غير متاح |

| الطباعة بالشاشة الحريرية | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | غير متاح | < 1 ميكرومتر |

| التخميل | الفولاذ المقاوم للصدأ | لا يوجد | لم يتغير | 5 ميكرومتر - 25 ميكرومتر |

هل تريد أن تجعل تصميمك حقيقة واقعة؟

لنبدأ

مشروع جديد اليوم

اتصل بمهندسينا على الفور وسنساعدك بسرعة في تحديد الحل الأفضل لك بناءً على احتياجاتك.

Tour Our Hermle CNC Machining Center

Discover the efficiency of GCH’s incredible line of CNC turning machines—delivering precision parts in just 24 hours.

Our CNC Machining for Various Industrial Applications

At GCH, we provide advanced CNC machining solutions designed to meet the diverse needs of industries such as aerospace, automotive, medical, electronics, and consumer goods. Our state-of-the-art CNC machines enable us to manufacture high-precision components with complex geometries and tight tolerances, ensuring reliability and performance in critical applications.

High Precision

Our advanced CNC technology ensures that each component meets stringent tolerances and design specifications, providing exceptional machining accuracy. This high level of precision is crucial for industries where exact dimensions are paramount.

Rapid Turnaround

GCH boasts efficient machining capabilities that allow us to deliver custom parts in a short timeframe. Our commitment to quick delivery helps our clients meet tight deadlines and accelerate their product development cycles.

Diverse Material Options

We can work with a wide range of materials, including metals and plastics, catering to the specific needs of various projects. This versatility allows us to accommodate unique design requirements and industry standards.

ISO 9001 Certification

GCH's facilities are ISO 9001 certified, ensuring consistency and excellence in quality management and production processes. This certification reflects our dedication to maintaining high standards and delivering reliable results for our clients.

What's CNC Machining?

CNC Machining, or Computer Numerical Control Machining, is a manufacturing technique where computer-controlled devices are used to remove layers from a material, creating detailed parts or components. Through a combination of tooling and precise machine movement, it produces parts to exact specifications.

What's CNC Machining?

The CNC machining process begins by designing a part in CAD software. This design is then converted into a set of machine commands using CAM software. The CNC machine reads these commands to precisely cut and shape the material, producing a finished part that matches the digital design.

What are the Advantages of CNC Machining?

CNC Machining offers unparalleled precision and repeatability, making it a top choice for industries requiring intricate parts. Its ability to handle a variety of materials, from metals to plastics, combined with fast production times and consistent quality, makes it an essential method in modern manufacturing.

What's the Difference Between 3D Printing and CNC Machining?

3D printing is an additive manufacturing method, building parts by depositing material layer by layer. In contrast, CNC machining is a subtractive method, starting with a solid block of material and removing sections until the desired part is achieved. While 3D printing is often favored for complex geometries and rapid prototyping, CNC machining excels in durability, precision, and material versatility.

FAQs About GCH CNC Services

GCH PROCESS is proficient in facilitating the production and prototyping of large machined parts, be it metal or plastic. We boast a substantial CNC machining build envelope measuring 2000 mm x 1500 mm x 300 mm. This ensures we can accommodate even sizable parts, including those tailored for furniture or architectural applications.

Absolutely! The exact tolerance we offer is contingent upon your specific requirements. For CNC machining, our metal components adhere to the ISO 2768-m standards, while our plastic parts align with ISO 2768-c standards. It’s worth noting that the demand for higher precision will correspondingly increase the cost.

Of course! GCH PROCESS has the capability to produce upwards of 10,000 diverse prototypes on a monthly basis, spanning from simple to intricate designs. Our infrastructure is bolstered by 120 state-of-the-art CNC machines, and we pride ourselves on having a team of over 100 skilled technical experts.

GCH PROCESS CNC Services is versatile in terms of material compatibility. Commonly used CNC materials include metals like aluminum, steel, brass, and copper, as well as plastics such as ABS, Polycarbonate, and POM. However, specific materials availability might vary, so it’s always a good idea to check directly with the service provider.

The expense associated with our CNC machining service is variable and directly influenced by the distinct attributes of your project, including its design and tolerance specifications. The machining duration for the chosen material is another key determinant of the cost. To illustrate, should you require a part where the combined machining and material expense is $2, with an additional setup charge of $200, the total cost for a singular part would amount to $202. Contrastingly, should you commission the production of 200 identical parts, the cost per unit would be just $3! Learn more about the تكاليف التصنيع الآلي باستخدام الحاسب الآلي CNC.

GCH PROCESS caters to both one-off prototype and large-scale production runs. Thus, there is typically no strict MOQ. Whether you need a single part or thousands, GCH PROCESS aims to provide a solution.

Lead times can vary based on the complexity of the design, the chosen material, and the current workload at GCH PROCESS. However, one of the advantages of CNC machining is its speed, especially for simpler parts. Once the setup is complete, machining times can be relatively quick. Parts delivered as fast as 1 day! But for an accurate estimate, it’s best to request for quotes directly.