Introduction to CNC Milling

CNC (Computer Numerical Control) milling is an advanced metal cutting process that leverages computer automation to produce precise shapes with high efficiency. The process starts with creating a CAD (Computer-Aided Design) model, which is then converted into CNC machine instructions through CAM (Computer-Aided Manufacturing) software. These instructions guide the CNC machine to manufacture the part. While the process may seem straightforward, it involves intricate details, from CAD and CAM software to tool selection and machine parameters.

What is CNC Milling?

CNC milling is a computer-controlled machining process that uses rotating tools to cut materials such as metals, wood, or plastics. The CNC system controls the sequence, path, spindle speed, and feed rate of the tool. Machines range from simple three-axis models to complex five-axis systems capable of producing intricate parts.

History of CNC Milling

In 1952, Richard Kegg, in collaboration with J.F. Reintjes at MIT, developed the first commercial CNC milling machine. Since then, CNC milling technology has evolved significantly, enabling the production of more complex machinery and advanced automation.

How CNC Milling Works

CNC milling uses rotating cutting tools to remove material from a fixed workpiece according to predetermined tool paths, cutting depths, and spindle speeds. The process includes several key steps:

- Creating the CAD Model: The process starts with developing a 3D CAD model, specifying the part’s dimensions, geometry, and shape. Design parts with minimal undercuts to ensure effective machining.

- Converting CAD to CNC: CAM software is used to convert the CAD model into a CNC program, typically written in G-code or M-code. The program specifies machining parameters, tool movements, and other critical functions.

- Preparing the CNC Machine: The machine operator imports the CNC program, sets up the tools, spindle, and workholding devices, and inserts the pre-machined blank into the machine.

- Executing the Program: The CNC machine executes the program line by line, performing the specified machining operations to produce the part.

Types of CNC Milling Operations

Various milling operations are employed in CNC machining, each suitable for different applications:

- Face Milling: Cutting surfaces perpendicular to the tool axis.

- Angular Milling: Removing material at an angle to the workpiece.

- Form Milling: Creating irregular surfaces, such as curves.

- Gang Milling: Using multiple tools simultaneously to increase productivity.

Essential CNC Milling Equipment

CNC milling requires several key pieces of equipment:

- Worktable: Holds the workpiece in place during machining.

- Saddle: Supports and guides the worktable’s movement.

- Knee: Provides vertical adjustment to accommodate different part thicknesses.

- Spindle: Holds and rotates the cutting tool.

- Arbor: The tool shaft mounted on the spindle.

- Column: Supports the spindle, especially in vertical or angular milling.

- Machine Tools: Various cutting tools, such as end mills.

- Interface: The communication point for the operator and the CNC machine, typically a keyboard and display screen.

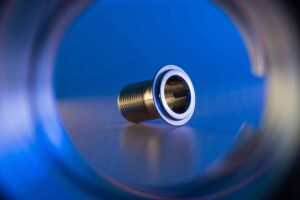

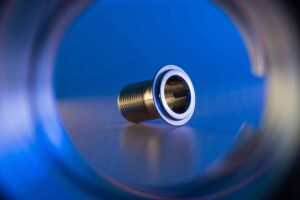

Applications of CNC Milling

CNC milling is widely used across multiple industries, including automotive, aerospace, agriculture, construction, electronics, and consumer goods. For example, in aerospace, it is used to manufacture engine components, fuel tank panels, and landing gear. In the medical field, it produces surgical instruments and implants. The versatility of CNC milling allows it to handle a variety of materials, including metals, plastics, ceramics, and composites.

Advantages of CNC Milling

CNC milling offers unmatched precision, enabling the efficient production of parts with tight tolerances. The automation of the CNC process reduces manual intervention, ensuring consistent quality and lowering labor costs. High productivity and the ability to produce complex geometries are significant advantages of CNC milling.

Limitations of CNC Milling

The primary limitation of CNC milling is cost. Basic machines capable of batch production can be expensive, while advanced multi-axis machines are even more costly. Additionally, part size is constrained by machine dimensions, and complex geometries may require specialized tools or multi-axis machines. Human errors, such as programming mistakes or improper tool setup, can also lead to part defects and increased scrap rates.

Cost of CNC Milling

The cost of CNC milling varies based on the complexity of the machine. Basic horizontal or vertical mills may cost around $10,000, while advanced five-axis machining centers can reach up to $300,000.

GCH’s CNC Milling Services

GCH offers customized CNC milling services suitable for various materials and industries. Our capabilities include three-axis, four-axis, and five-axis milling, enabling rapid prototyping, toolmaking, and end-use production. Contact GCH for all your CNC machining needs.

Conclusion

CNC milling is a versatile and precise manufacturing process widely used across industries. This guide covers its history, working principles, methods, equipment, applications, advantages, and limitations. For more information or to request a quote, contact a GCH representative.

Disclaimer

This document is for informational purposes only. GCH makes no representations or warranties regarding the accuracy or completeness of the provided information. Performance parameters and design features should not be construed as guarantees. For specific requirements, please refer to our terms and conditions.