What is Rapid Prototyping?

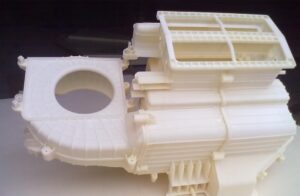

Rapid prototyping is the expedited creation of a physical part, model, or assembly using 3D computer-aided design (CAD). This process typically involves additive manufacturing, more commonly known as 3D printing. When the prototype closely resembles the intended final product, it is referred to as a high-fidelity prototype. Conversely, a significant difference between the prototype and the final product indicates a low-fidelity prototype.

How Does Rapid Prototyping Work?

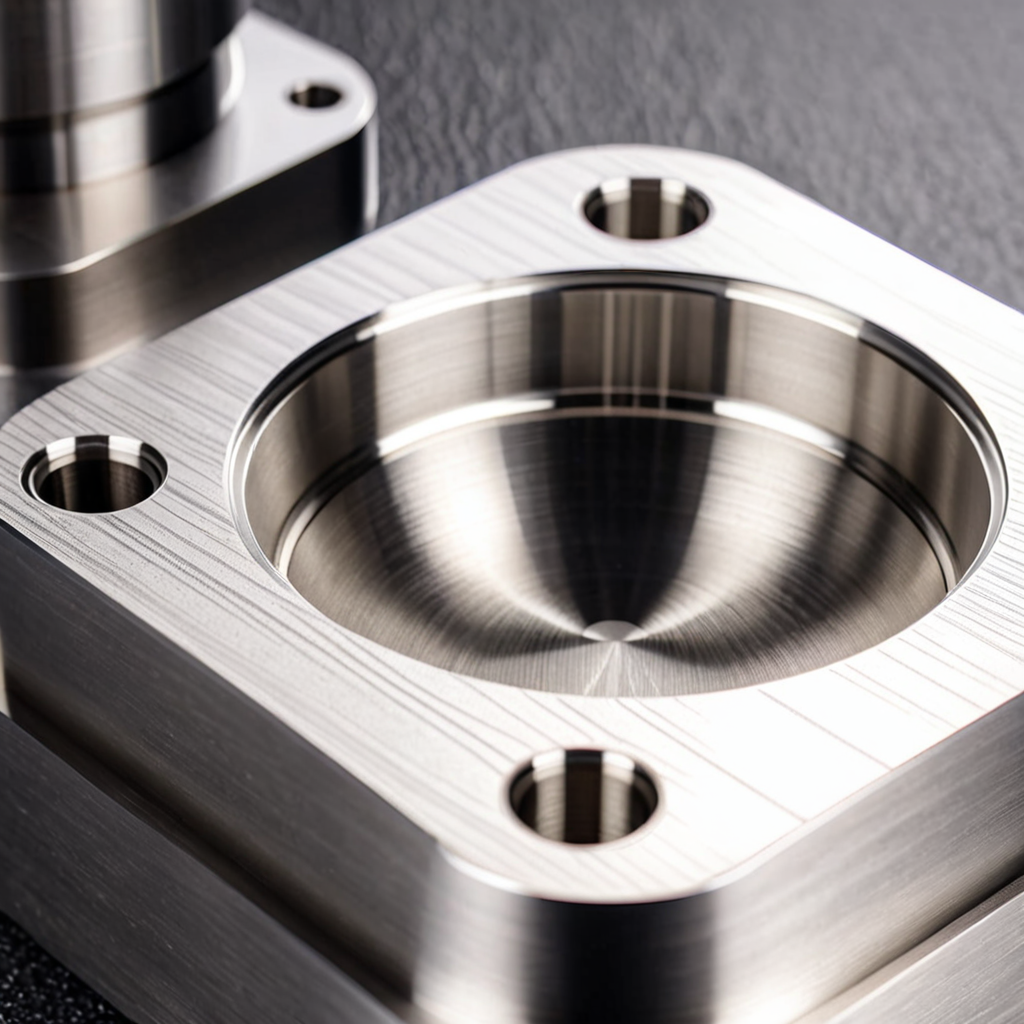

Rapid prototyping (RP) encompasses various manufacturing technologies, with most relying on layered additive manufacturing. Other methods include high-speed machining, casting, molding, and extruding. Besides additive manufacturing, more conventional techniques can create prototypes, such as:

- Subtractive: Material is carved from a block to achieve the desired shape using milling, grinding, or turning.

- Compressive: Semi-solid or liquid material is forced into the desired shape and solidified, such as in casting, compressive sintering, or molding.

Types of Rapid Prototyping

- Stereolithography (SLA) or Vat Photopolymerization: SLA is a fast and affordable technique that uses a bath of photosensitive liquid solidified layer-by-layer with UV light.

- Selective Laser Sintering (SLS): SLS builds prototypes from metal or plastic powders, layer by layer, using a laser to sinter the material. However, the resulting parts might need secondary finishing due to rough surfaces.

- Fused Deposition Modelling (FDM) or Material Jetting: FDM uses thermoplastic filament melted and deposited layer by layer. It’s inexpensive and suitable for non-industrial desktop 3D printers.

- Selective Laser Melting (SLM) or Powder Bed Fusion: SLM uses fine metal powders melted by a high-powered laser or electron beam to create high-strength, complex parts. This method is popular in aerospace, automotive, defense, and medical industries.

- Laminated Object Manufacturing (LOM) or Sheet Lamination: LOM builds parts by bonding thin laminates cut with lasers or other cutting devices. It’s less sophisticated but doesn’t require controlled conditions.

- Digital Light Processing (DLP): Similar to SLA, DLP uses a conventional light source for polymerization. It often requires support structures and post-build curing.

- Binder Jetting: Binder Jetting uses a powder bed and liquid binder to form parts layer by layer. It’s suitable for producing multiple parts simultaneously but results in lower strength compared to SLS.

Applications of Rapid Prototyping

Rapid prototyping aids product designers in the fast manufacturing of representative prototype parts, facilitating visualization, design, and development of manufacturing processes before mass production. Initially used in the automotive industry, its applications have spread to medical, aerospace, and other industries. Rapid tooling, another application, involves creating parts used as tools in other processes.

Advantages of Rapid Prototyping

- Early Visualization: Provides a complete picture of how a product will look or perform early in the design and manufacturing cycle.

- Cost-Effective: Automated processes require fewer staff and materials, reducing costs.

- Precision: CAD helps minimize material waste and avoids the need for specialized tools for each new prototype.

- Rapid Iteration: Facilitates quick modifications based on design changes and user feedback.

- Enhanced Communication: Allows designers to present tangible concepts to stakeholders for better understanding and approval.

- Customization and Flexibility: Supports incorporating customer requirements cost-effectively.

Cost of Rapid Prototyping

The cost of rapid prototyping services depends on several factors, including the volume and size of the parts, surface finish, materials used, and the extent of post-manufacture processing required.

Rapid Prototyping Services at GCH

GCH offers extensive expertise in 3D printing technologies and additive manufacturing processes. Our rapid prototyping services are designed to assist with technology and manufacturing process development. We are dedicated to helping industry improve safety, quality, efficiency, and profitability in all aspects of materials joining technology.

اتصل بنا

For more information about our rapid prototyping services, please contact us at Ophliea@gchprocess.com.

By leveraging GCH’s rapid prototyping services, your company can gain a competitive edge in product development, ensuring high-quality prototypes that meet your specific requirements.