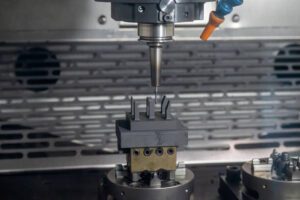

GCH Process offers rapid, high-quality CNC prototyping services designed for critical applications across diverse industries, including aerospace, defense, robotics, industrial, automotive, electronics, energy, hardware, and consumer products. Our skilled engineers and machinists, combined with cutting-edge equipment and stringent quality control, ensure superior accuracy, tight tolerances, and high-quality parts.

Capabilities:

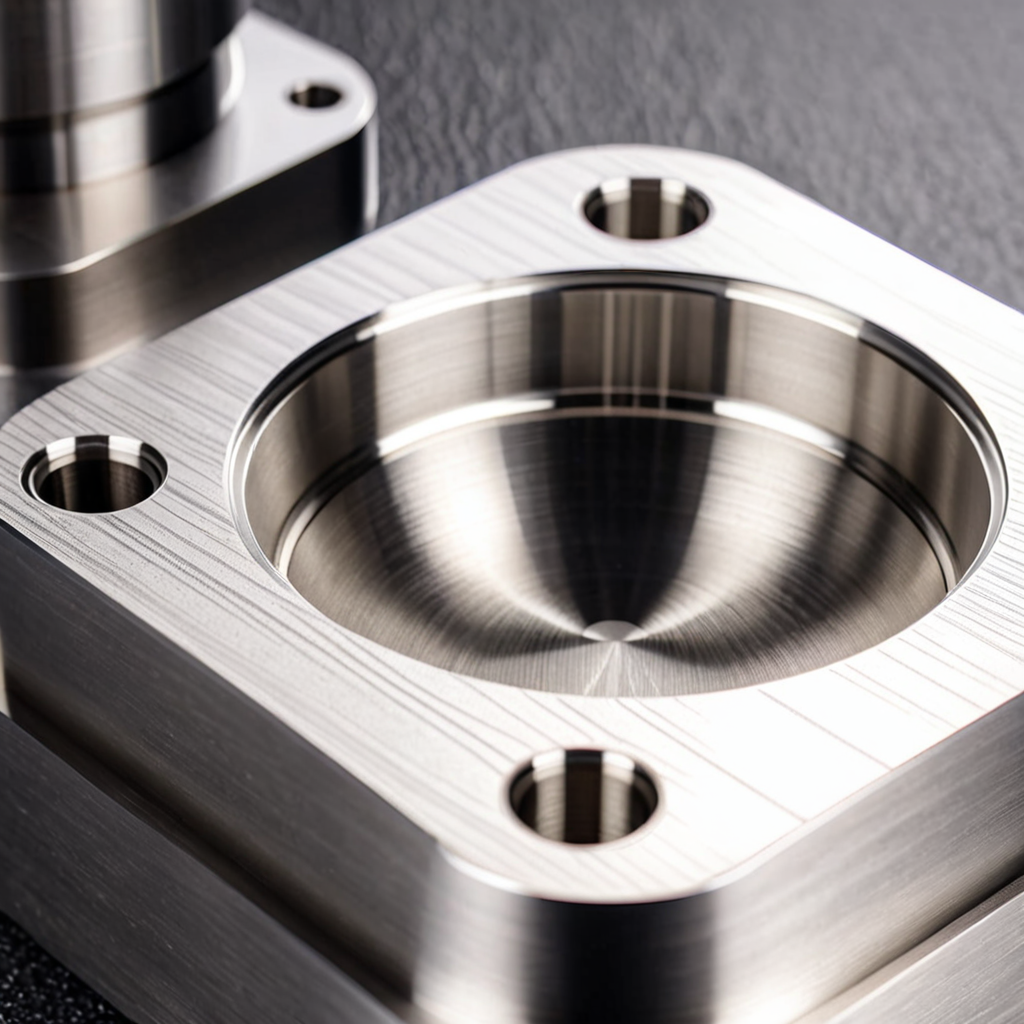

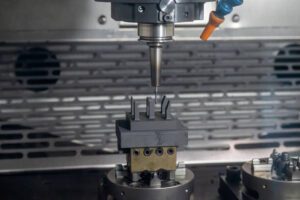

- 3-Axis and 5-Axis Milling: Create complex geometries and intricate features with high-precision surfaces.

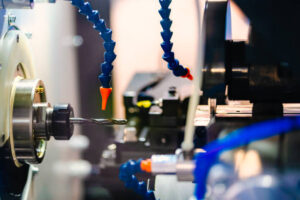

- Turning: Manufacture precision cylindrical parts, shafts, and components with tight tolerances.

- Multi-Axis Mill-Turn Centers: Efficiently produce complex parts by combining milling and turning capabilities.

- Diverse Material Expertise: Work with engineering plastics, aluminum, steels, exotic alloys, and composites.

- Secondary Operations: Provide deburring, surface finishing, plating, and assembly services.

Why Choose GCH Process for CNC Prototyping Services?

- Focus on Precision: Utilize state-of-the-art machines and skilled machinists for exceptional accuracy.

- Industry Expertise: Demonstrated success in industries requiring tight tolerances and high-quality parts.

- Competitive Turnaround & Pricing: Streamlined processes for both prototypes and high-volume production.

What is CNC Machining?

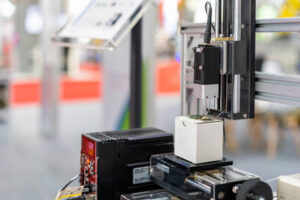

CNC machining, or Computer Numerical Controlled machining, is a manufacturing process that uses computers to control the movement of machining tools. It encompasses various techniques such as milling, drilling, and cutting, and can even include 3D printing. Common CNC machines operate in 3 axes, though some machines also control the workpiece rotation, providing 4-axis or 5-axis machining capabilities.

Advantages of CNC Machining

CNC machining offers significant benefits over traditional methods:

- Higher Accuracy: Achieve tight tolerances, often around ±0.0002mm.

- Consistency: Computer control minimizes human error.

- Faster Production: Automation shortens fabrication time.

- Lower Costs: Reduced operator intervention decreases production costs.

- Enhanced Safety: The automated process minimizes direct contact with tools and materials.

CNC Machining Processes

CNC machining can be categorized into two main types:

Subtractive Machining: Involves removing material from a workpiece.

- Turning:Uses a lathe to rotate the workpiece at high speeds, removing material with a tool.

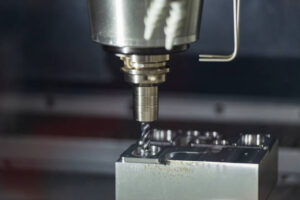

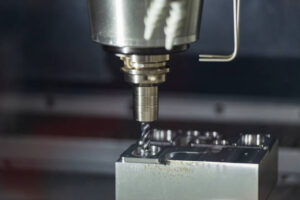

- Milling:Involves a rotating tool that removes material from a stationary workpiece.

- Drilling:Creates holes in the workpiece, which can be perpendicular or angled.

- Grinding:Uses an abrasive wheel to refine the workpiece by removing small amounts of material.

- EDM (Electrical Discharge Machining):Uses electrical discharges to remove material, with variations like sinker and wire EDM.

- Waterjet Cutting:Uses high-pressure water with abrasives to cut through various materials.

- Laser Cutting:Employs a focused laser beam to cut sheet metal.

- Plasma Cutting:Utilizes high-temperature gas jets to cut electrically conductive materials.

Additive Machining: Involves adding material to create the desired shape.

- 3D Printing:Layers of material are deposited to form the final shape, commonly used for rapid prototyping.

Learn More About Our Capabilities

GCH Process: Your Technology-Driven Manufacturing Partner

GCH Process excels in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our technology-driven approach ensures high quality, optimized costs, and seamless supply chain management.

Key Services:

- Precision CNC Machining:High-quality custom parts and components.

- Advanced 3D Printing:Rapid prototyping and complex production parts.

- Sheet Metal Fabrication:Custom fabrication solutions for various materials.

- Injection Molding:Scalable production for plastic parts.

Why Choose GCH Process?

- AI-Powered Manufacturing:Data and AI optimize processes for superior quality and minimized costs.

- Extensive Production Capacity:A wide network ensures both low and high-volume production.

- End-to-End Expertise:Our team of engineers and product developers ensures manufacturability and excellent service.

- Single-Source Solution:Streamlined supply chain, reduced overhead, and just-in-time delivery.

- Online CNC Machining Services:Fast, easy, and reliable way to create high-quality, custom-made parts.

خدمات النماذج الأولية باستخدام الحاسب الآلي الرقمي

GCH Process provides specialized CNC prototyping services, helping you bring your ideas to life with high precision and rapid turnaround times. Whether for local businesses or online clients, our expert team delivers customized CNC machining solutions tailored to your specific project needs.

Experience the GCH Process difference. Get a fast quote for your manufacturing needs today!